High-density ferroelectric data storage method realized by piezo response force microscope (PFM) probe

A piezoelectric force microscope and data storage technology, applied in digital memory information, information storage, static memory, etc., can solve the problems of complex hard disk structure, high power consumption and noise, hard disk damage, etc., to achieve large-capacity information storage, Easy to operate and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

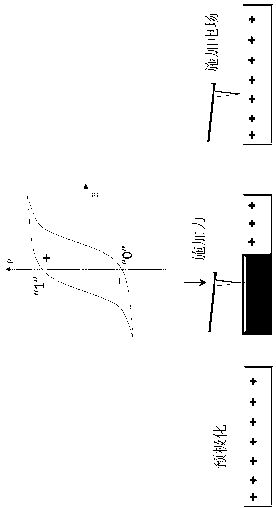

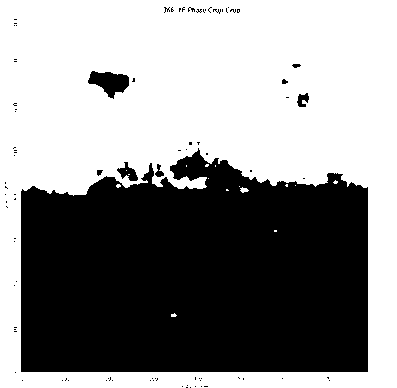

[0030] First, prepare a vinylidene fluoride-trifluoroethylene copolymer P(VDF-TrFE) solution, the molar ratio of vinylidene fluoride to trifluoroethylene is 68:32, the solvent is 2-butanone, and its concentration is 10 mg / mL ; Then a 50 nm-thick film was fabricated on a gold-coated silicon wafer substrate by spin coating at 2000 rpm for 40 seconds; then its storage performance was tested using a piezoelectric force microscope (PFM) from NT-MDT. ,like figure 1 As shown, the main steps are as follows: first, pre-polarization of the ferroelectric polymer film is carried out, and the PFM probe is used to perform pre-polarization treatment on the film with a voltage of -10 V; A constant force field is applied to the upper half of the surface, and the magnitude of the force is 200nN. At this time, its phase changes and can maintain this state. The phase diagram is as follows figure 2As shown, the upper part of the figure is erased by force field, and its phase is changed, so that...

Embodiment 2

[0032] The difference between this embodiment and Example 1 is that the concentration of the polymer solution of the vinylidene fluoride-trifluoroethylene copolymer is 5 mg / mL. A thin film sample with a thickness of 20 nm was prepared by the same method. On its surface, a constant force can also be used to store information and erase data with an electrical signal, with a force of 300nN.

Embodiment 3

[0034] The difference between this embodiment and Example 1 is that the concentration of the polymer solution of the vinylidene fluoride-trifluoroethylene copolymer is 20 mg / mL. A thin film sample with a thickness of 150 nm was prepared by the same method. On its surface, a constant force can also be used to store information and erase data with an electrical signal, with a force of 400nN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com