Combustion engine capable of using electric heat energy in independent mode or in auxiliary mode

An internal combustion engine, a single technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of limited thermal efficiency of internal combustion engines, and achieve the effect of promoting the work of the piston and increasing the working air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

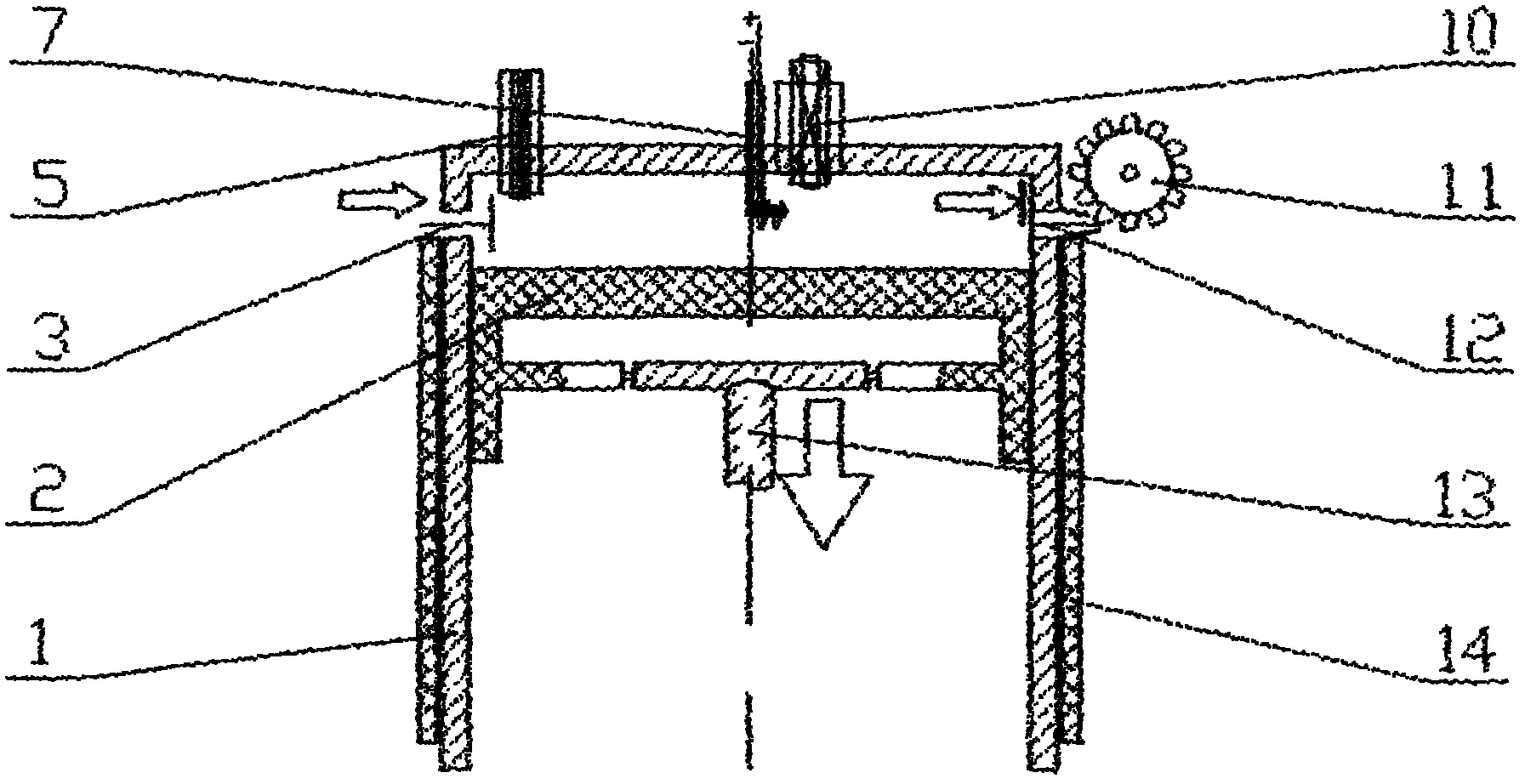

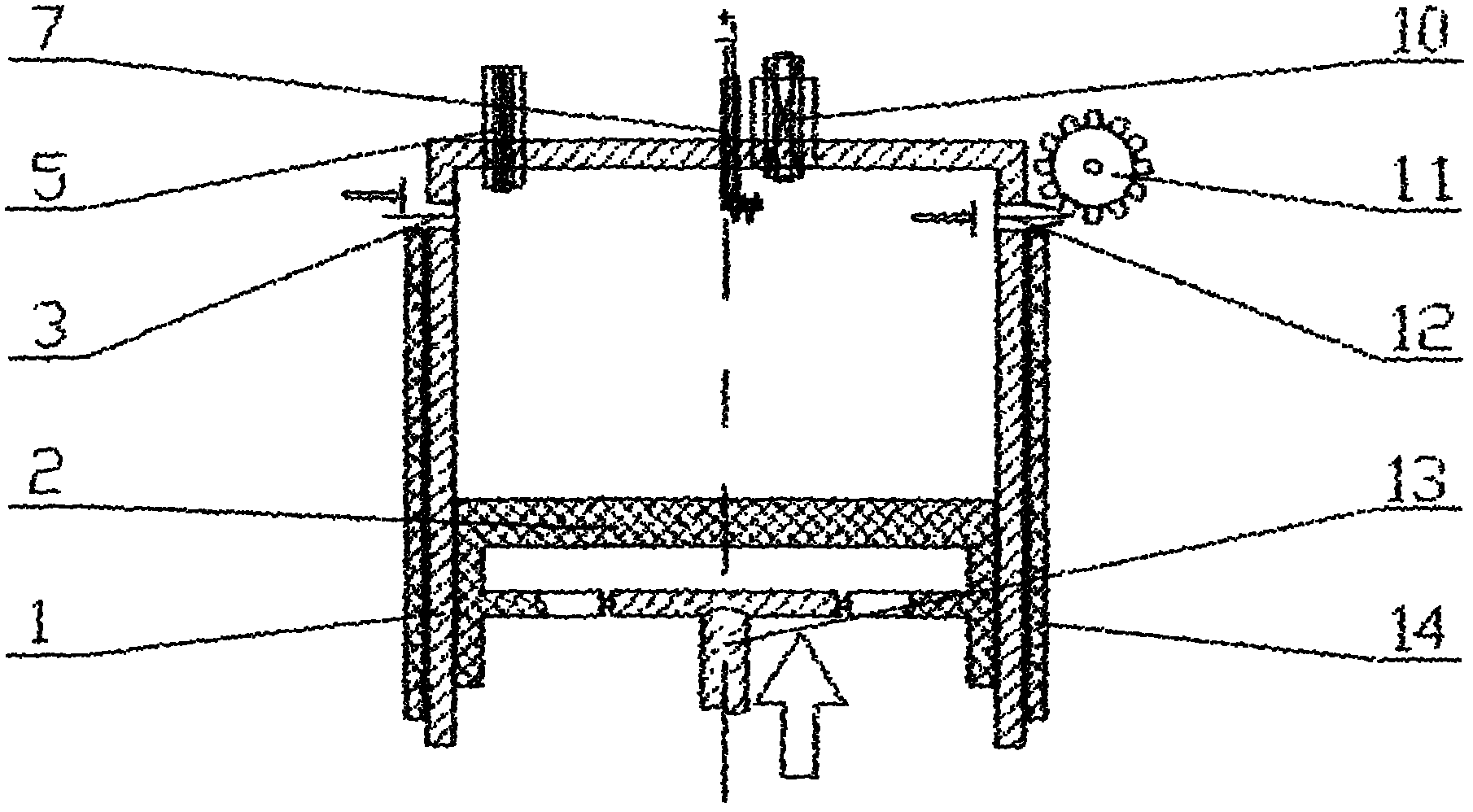

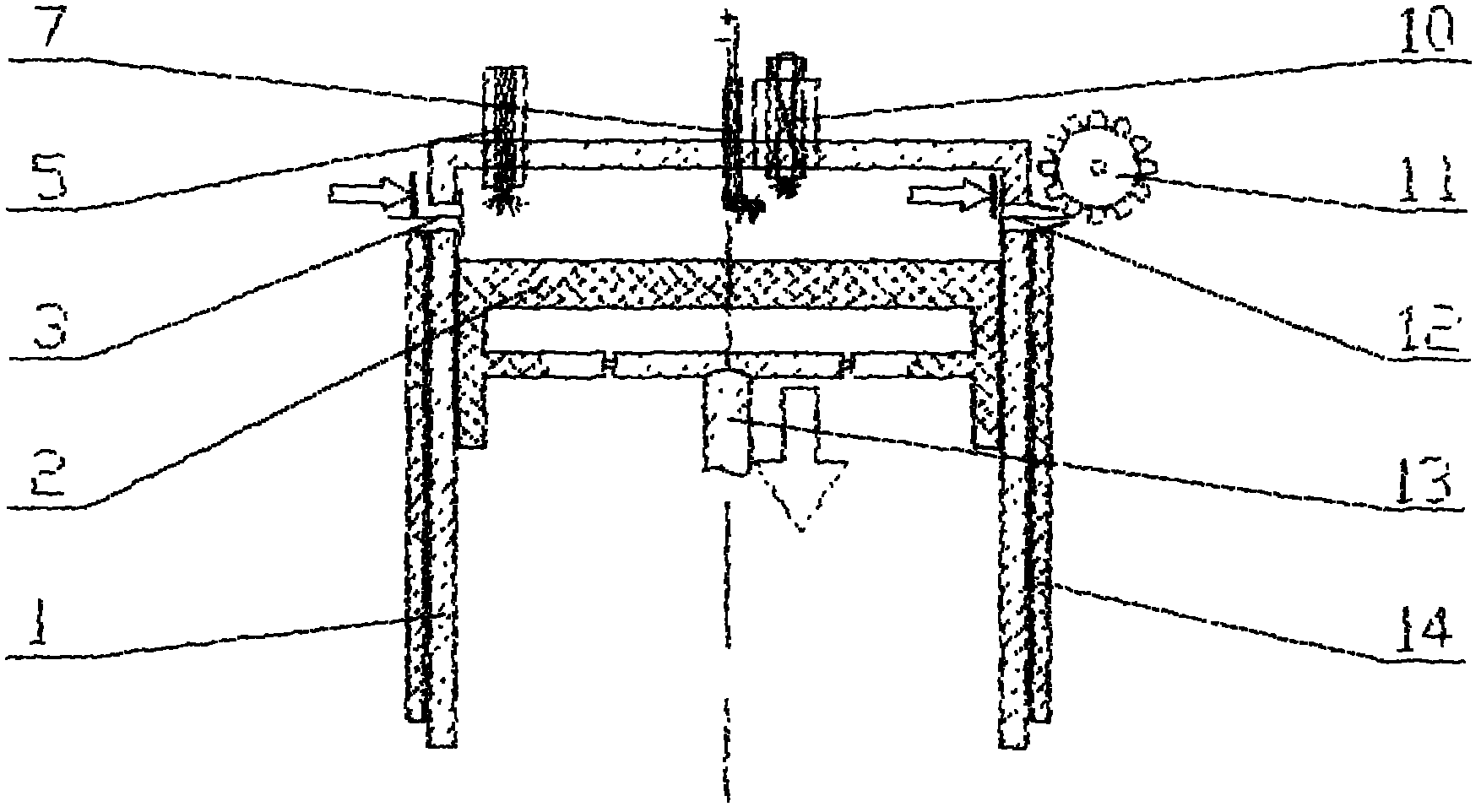

[0028] Embodiment 1 selects the working process when applying single electric heat energy for heating, and its work just requires that the air intake valve (3) and fuel injection nozzle (5) are in the locked closed state, and the electric heating rod (7) keeps energizing work all the time. Embodiment 2 selects the course of work of the single heat supply of electric heating energy to be basically the same (can refer to Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 ), it is also required that the air intake valve (3), the intake gas valve (6) and the fuel injector (5) are all locked and closed, the inner cylinder isolation door (4) is kept open, and the electric heating rod (7) is kept energized Work, other working processes are completely consistent with the above-mentioned two-stroke working processes.

[0029] Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com