A Construction Method of Circular Drilling for Cut-off Wall Grooving

A circular drilling and construction method technology, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of increasing project costs, delaying the construction period, and burying drills, so as to speed up the construction progress and ensure the quality of the project.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

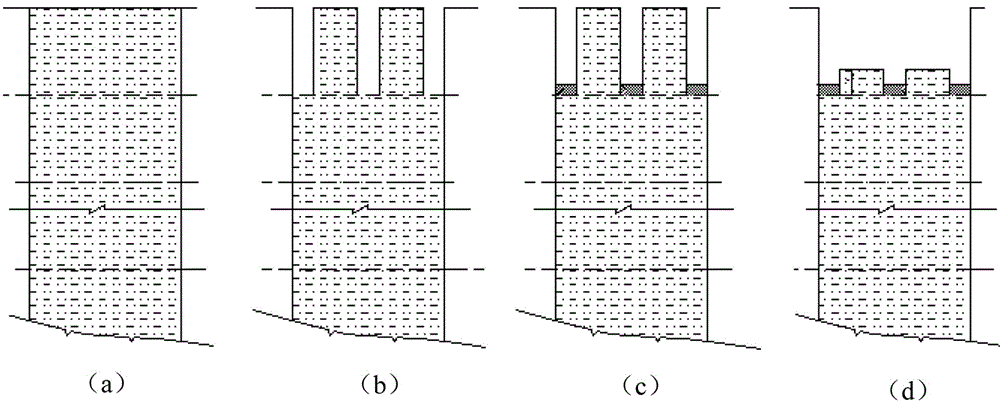

[0022] see figure 1 (a)— figure 1 (d), a construction method of circular drilling for cut-off wall grooves. The construction cycle in the groove section is divided: according to the hole depth of the groove section, the deep covering layer is divided into several cycles from top to bottom, and the depth of each cycle is at least The groove depth is preferably 10m. Construction cycle division of slot section, such as figure 1 as shown in (a);

[0023] Construction of the main hole in the first cycle: when the trough construction is carried out in the groove section, it is also divided into the main hole and the auxiliary hole, and the main hole is constructed first, and then the auxiliary hole is constructed. When using percussion drilling rig to construct the main hole, the hole depth should be 10m. When each main hole is drilled to a depth of 10m, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com