Powdered coal coking device and powdered coal coking method

A technology for pulverized coal and equipment, which is applied to pulverized coal coking equipment and coking field, can solve problems such as temperature imbalance, affecting tar quality, and unstable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

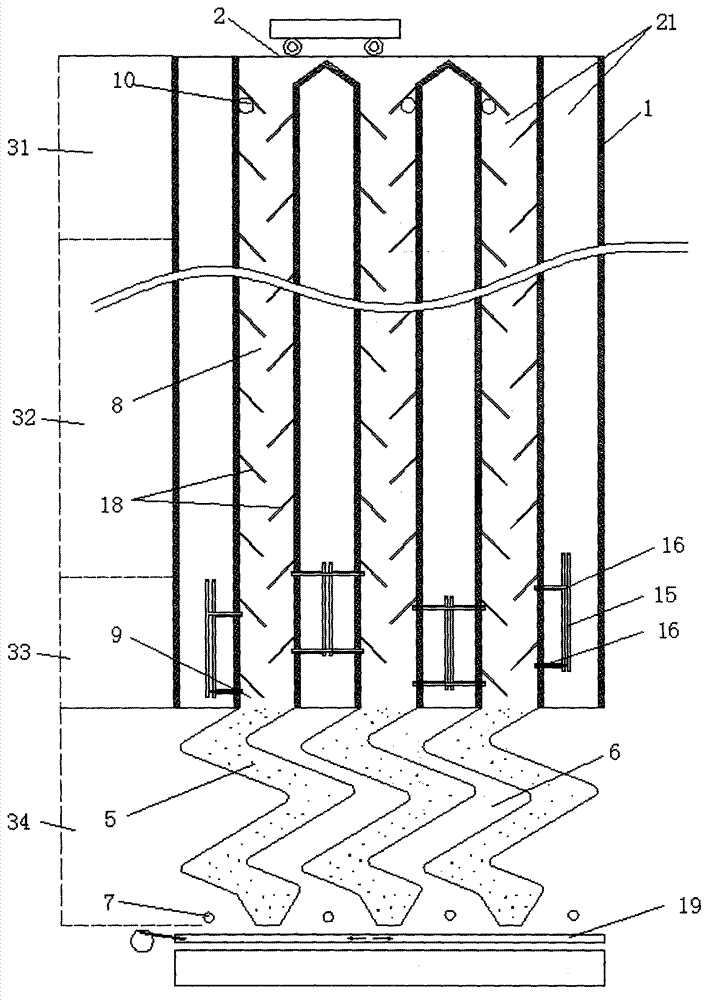

[0096] Example 1 Coking method of pulverized coal coking chamber 8 with internal heating structure

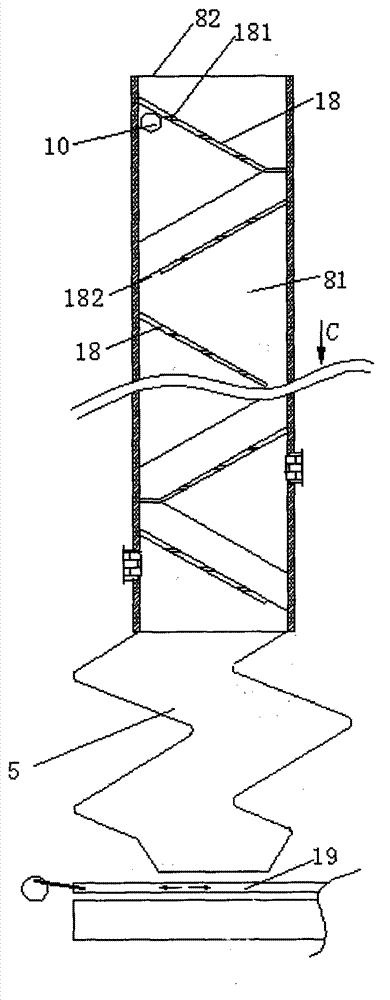

[0097] Such as figure 1 As shown, when the pulverized coal coking chamber 8 has an internal heating structure, the pulverized coal coking chamber 8 is divided into a preheating and drying zone 31, a pyrolysis and carbonization zone 32, a combustion coking zone 33 and a semi-coke cooling zone 34, wherein : the preheating and drying area 31 includes several heat exchange units located at the upper part of the carbonization chamber for preheating and drying of pulverized coal; The dried pulverized coal is subjected to low-temperature pyrolysis, and the volatile matter in the pulverized coal is dry-distilled; the combustion and coking zone includes several heat exchange units located in the middle and lower part of the carbonization chamber, which are used to generate heat carrier gas, and pyrolyze the pyrolysis and carbonization zone. The pulverized coal is further pyrolyzed at m...

Embodiment 2

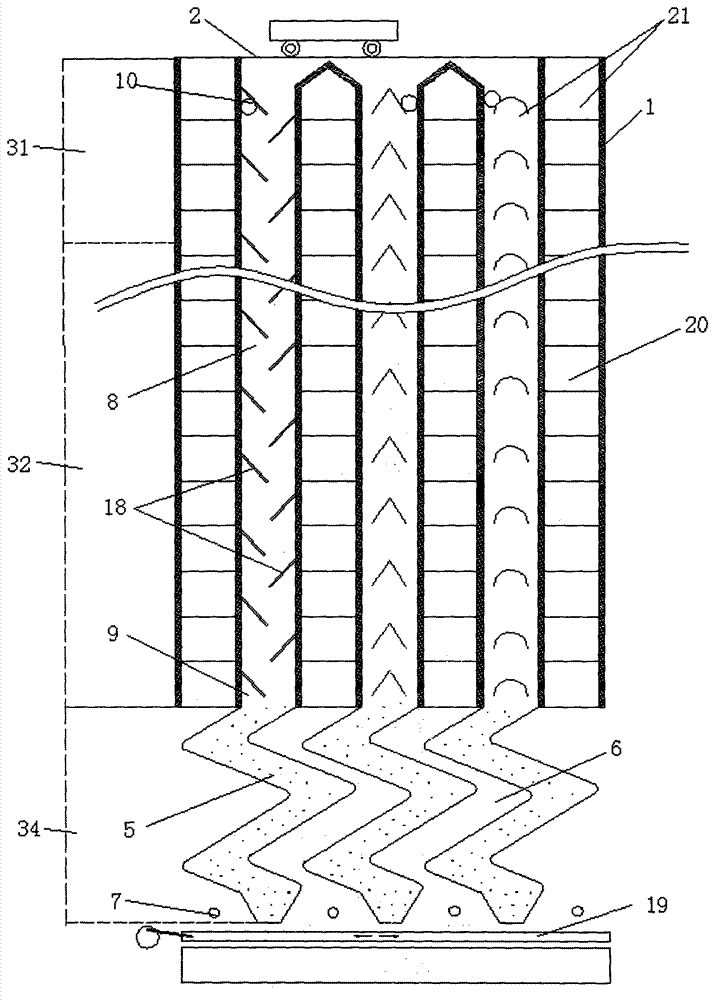

[0103] Example 2 Coking method of pulverized coal coking chamber 8 with external heating structure

[0104] Such as figure 2 As shown, when the pulverized coal coking chamber 8 is an external heating structure, the carbonization chamber is divided into a preheating and drying zone 31, a pyrolysis and carbonization zone 32, and a semi-coke cooling zone 34, wherein: the preheating and drying zone 31 includes Several heat exchange units in the upper part of the chamber are used for preheating and drying of pulverized coal; the pyrolysis and carbonization area contains several heat exchange units located in the middle and lower parts of the carbonization chamber for pyrolysis of preheated and dried pulverized coal , to dry out the volatile matter in pulverized coal to produce powdery semi-coke; the semi-coke cooling zone includes several heat exchange units located in the lower part of the carbonization chamber and a curved semi-coke discharge channel, which is used to use high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com