Method for producing holder blank with ether anhydride type polyimide molding powder composite material

A polyimide and composite material technology, applied in the field of bearing cages, can solve problems such as no related reports, achieve high tensile strength, high temperature resistance and excellent tribological properties, and improve tribological properties and high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

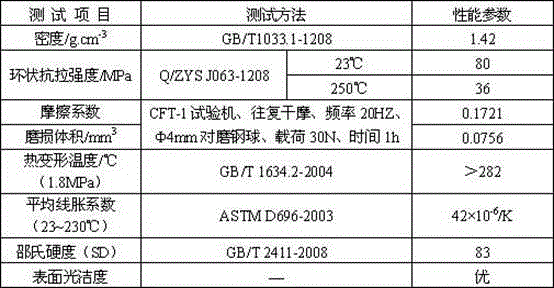

[0028] The invention is a method for making a cage blank from an ether anhydride type polyimide molding powder composite material. The method uses the ether anhydride type polyimide molding powder as a base material and adding polyimide pulp And lubricating modified materials polytetrafluoroethylene and carbon nanotubes, the ether anhydride type polyimide molding powder composite material is passed through the bearing cage mold and hot pressed on the program-controlled hot press to obtain the ether anhydride type polyimide mold The cage blank made of plastic powder composite material has the characteristics of light weight, high tensile strength, high temperature resistance and friction resistance after reprocessing.

[0029] The method of the present invention includes five steps:

[0030] The first step is to dry the ether anhydride type polyimide molding powder and polyimide pulp;

[0031] The second step is to pre-open the polyimide pulp;

[0032] The third step is to prepare eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com