Cellulose nanocrystal/ethylene-vinyl acetate (EVA) gas separating membrane, preparation method thereof and application thereof

A technology of gas barrier films and nanocrystals, which is applied in transportation and packaging, flexible coverings, packaging, etc., can solve the problems of insufficient dispersion, small layered montmorillonite sheets, and the addition of fillers should not be too large, etc. Achieve the effect of simple preparation method and good water vapor barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

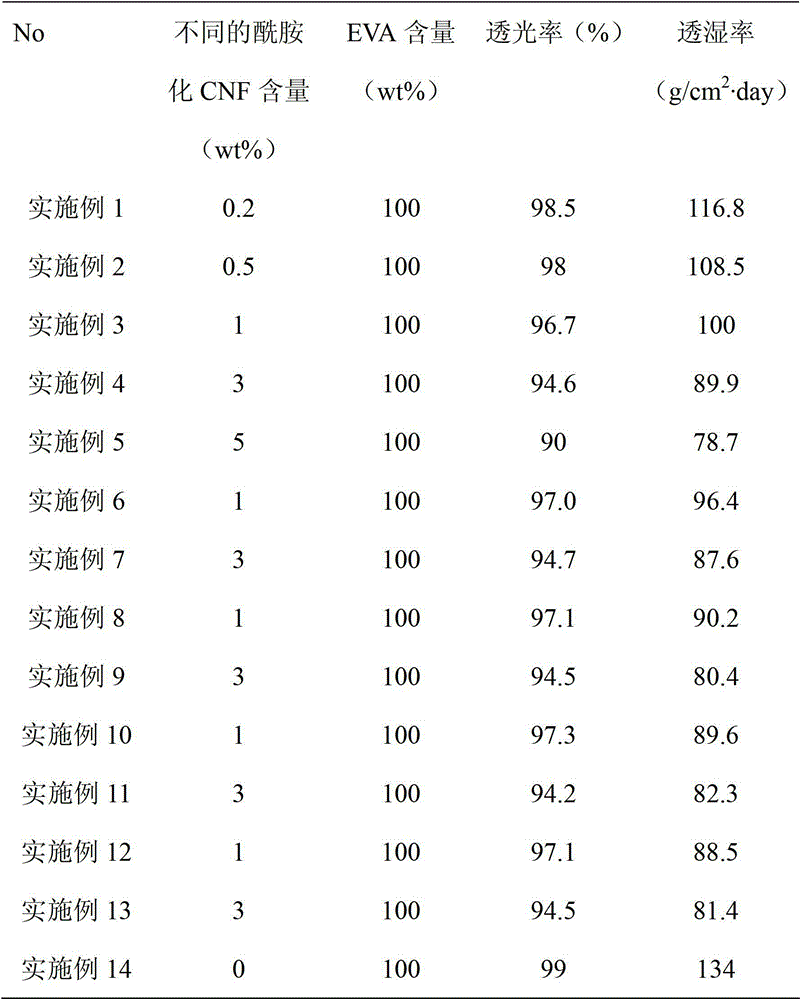

Examples

Embodiment 1

[0024] (1) Preparation of carboxylated cellulose nanocrystals: Weigh 1 g of cellulose nanocrystals (Aladdin's reagent) into a 250 mL three-necked round-bottom flask, and then add 100 mL of deionized water to form a suspension. NaBr (0.10 g, 1 mmol), 0.016 g of TEMPO reagent (Aladdin reagent), and NaClO solution (86 g / L, 1.27 g) were sequentially added, and the reaction was performed under magnetic stirring at 20° C. for 4 h. During the reaction process, 0.5 mol / L NaOH solution was continuously added dropwise with a dropping funnel to keep the pH value of the system around 10 and remained unchanged. After the reaction, add 30mL saturated saline, centrifuge (3000rpm, 5min) to obtain the product; then wash 4 times with 1mol / L NaCl solution, 4 times with 0.1mol / L HCl solution, and 4 times with deionized water; Dialyze in a beaker filled with deionized water for 3 days, and dry in a vacuum oven at 50° C. for 24 hours to obtain carboxylated cellulose nanocrystals. Determination of ...

Embodiment 2

[0029] (1) Preparation of carboxylated cellulose nanocrystals: Weigh 1 g of cellulose nanocrystals (Aladdin's reagent) into a 250 mL three-necked round-bottom flask, and then add 100 mL of deionized water to form a suspension. NaBr (0.10g, 1mmol) and NaClO solution (86g / L, 3.38g) were added in sequence, and the reaction was performed under magnetic stirring at 20°C for 4h. During the reaction process, 0.5 mol / L NaOH solution was continuously added dropwise with a dropping funnel to keep the pH value of the system around 10 and remain unchanged. After the reaction, add 30mL saturated saline, centrifuge (3000rpm, 5min) to get the product; then wash 3 times with 1mol / L NaCl solution, 3 times with 0.1mol / L HCl solution, and 3 times with deionized water; Dialyze in a beaker filled with deionized water for 3 days, and dry in a vacuum oven at 50° C. for 24 hours to obtain carboxylated cellulose nanocrystals. Weigh 0.100g carboxylated cellulose nanocrystals into a 100ml Erlenmeyer fl...

Embodiment 3

[0034] (1) Preparation of carboxylated cellulose nanocrystals: Weigh 1 g of cellulose nanocrystals (Aladdin's reagent) into a 250 mL three-necked round-bottom flask, and then add 100 mL of deionized water to form a suspension. NaBr (0.10 g, 1 mmol), 0.016 g of TEMPO reagent, and NaClO solution (86 g / L, 5.08 g) were added in sequence, and the reaction was performed under magnetic stirring at 20° C. for 4 h. During the reaction process, 0.5 mol / L NaOH solution was continuously added dropwise with a dropping funnel to keep the pH value of the system around 10 and remain unchanged. After the reaction, add 30mL saturated saline, centrifuge (3000rpm, 5min) to obtain the product; wash with 1mol / L NaCl solution 3 times, 0.1mol / L HCl solution 3 times, and deionized water 3 times; Dialyze in a beaker of deionized water for 3 days, and dry in a vacuum oven at 50° C. for 24 hours to obtain carboxylated cellulose nanocrystals. Weigh 0.100g carboxylated cellulose nanocrystals into a 100ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com