Preparation method of flame retardant type separant

A kind of isolation agent, flame retardant technology, applied in the field of preparation of functional isolation agent, to achieve the effect of not easy to spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

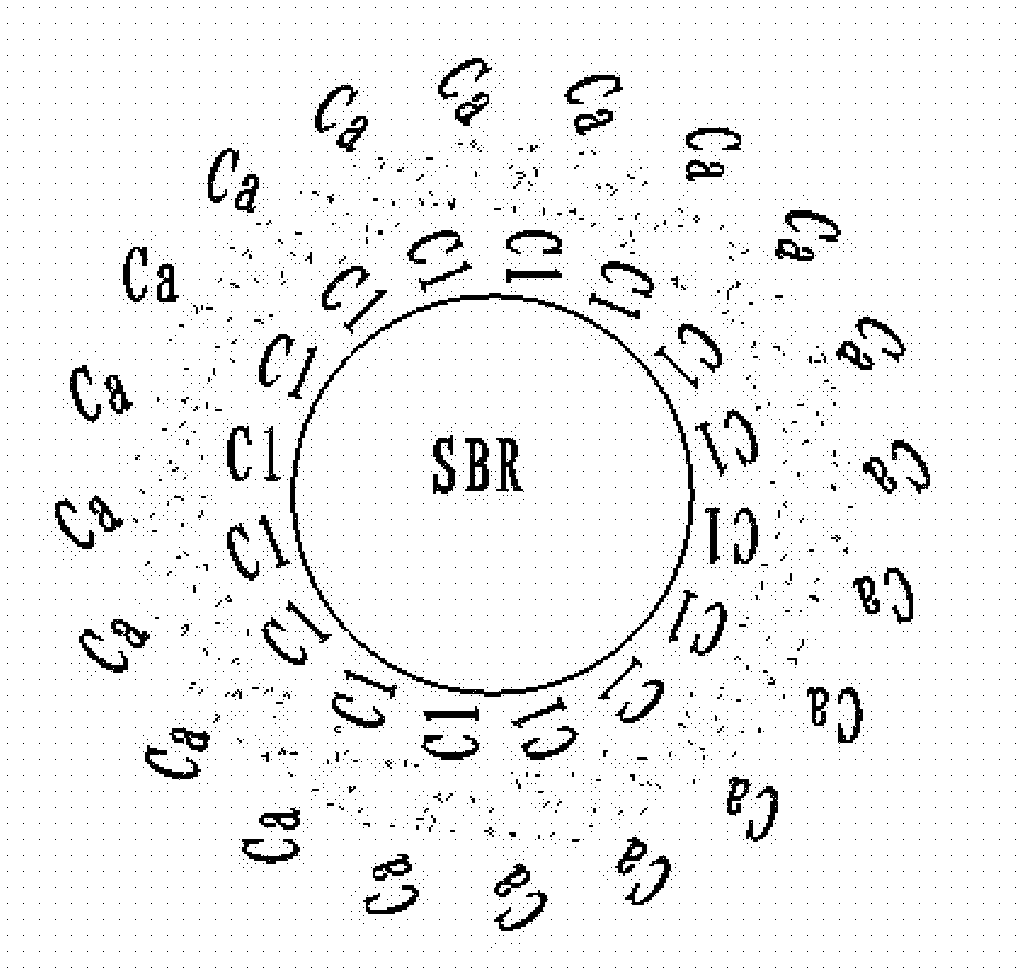

Image

Examples

Embodiment 1

[0025] Add 10mol monoenyl octadecanoic anhydride and 20mol CCl to the reactor 4 Stir to mix evenly, add 0.1mol of (PhCO 2 ) 2 Initiator, control the reaction temperature at 40°C, add 5% (w) NaOH solution to the reactor after reacting for 60 minutes to adjust the pH of the reaction solution to 8.5, and stir for 20 minutes to obtain a spacer for use. Get 500g of 20% (w) styrene-butadiene latex, add 40g of the aforementioned release agent, stir to make it evenly mixed, then add 50g of CaCl 2 Coagulation is carried out, the temperature of the coagulation tank is controlled at 40°C, and the obtained slurry is washed and dried to obtain powdered rubber. The oxygen index is 23.5%, which is flame retardant.

Embodiment 2

[0029] Add 10mol dienyl octadecanoic anhydride and 1molCCl to the reactor 4 Stir and mix evenly, add 0.05mol of (PhCO 2 ) 2 As an initiator, control the reaction temperature at 30°C, add 50% (w) NaOH solution to the reactor after reacting for 30 minutes to adjust the pH of the reaction solution to 8.5, and stir for 6 minutes to obtain a spacer for use. Take 500g of 20% (w) styrene-butadiene latex, add 10g of the aforementioned release agent, stir to make it evenly mixed, add 200g of CaCl 2 Coagulation is carried out, the temperature of the coagulation tank is controlled at 45°C, and the obtained slurry is washed and dried to obtain powdered rubber. The oxygen index is 24.8%, which is flame retardant.

Embodiment 3

[0033] Add 10mol triene octadecanoic anhydride and 60mol CCl to the reactor 4 Stir and mix evenly, add 0.3mol of (PhCO 2 ) 2 As an initiator, control the reaction temperature at 90°C, add 25% (w) NaOH solution to the reactor after 180 minutes of reaction to adjust the pH of the reaction solution to 8.9, and stir for 120 minutes to obtain a spacer for use. Get 500g of 20% (w) natural rubber latex, add 200g of the aforementioned release agent, stir to make it evenly mixed, add 10g of CaCl 2 Coagulation is carried out, the temperature of the coagulation tank is controlled at 55° C., and the obtained slurry is washed and dried to obtain powdered rubber. The oxygen index is 25.8%, which is flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com