Rapid powder transferring device for adjacent furnace of power station boiler and using method thereof

A power plant boiler and powder conversion technology, which is applied in the direction of combustion method, transportation and packaging, and conveying bulk materials, can solve the problems of poor safety, reduced powder conversion efficiency, and cumbersome process, so as to improve strength, improve powder conversion efficiency, and save energy. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

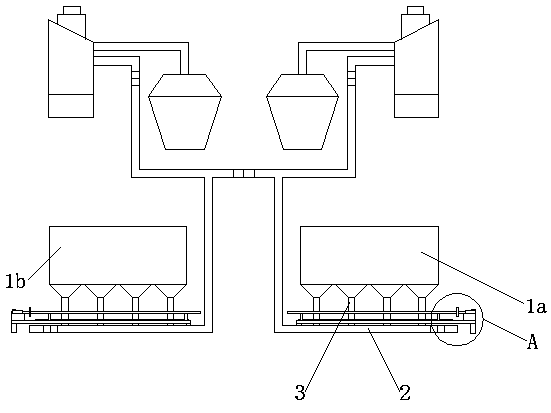

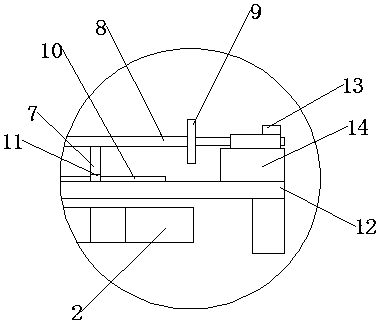

[0036] see figure 1, a power plant boiler adjacent furnace fast powder transfer device, comprising a first furnace powder bin 1a, a second furnace powder bin 1b and a pair of powder pumping branch pipes 2, the first furnace powder bin 1a and the second furnace powder bin 1b and a pair of There are many evenly distributed powder outlet pipes 3 connected between the powder pumping branch pipes 2, which play the role of transferring the coal powder in the first furnace powder bin 1a and the second furnace powder bin 1b. The above all belong to the prior art. This will not be repeated here.

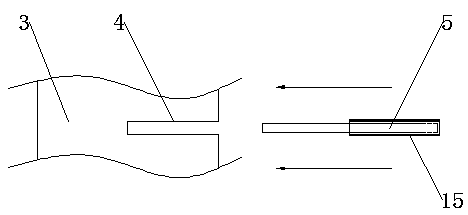

[0037] see Figure 3-4 , the right end of the lower powder outlet pipe 3 is dug with an arc-shaped through hole 4, and the lower powder outlet pipe 3 is inserted with a moving sealing plate 5, and the moving sealing plate 5 plays a role in blocking the lower powder outlet pipe 3, and the moving sealing plate 5 It includes a blocking part 501 and a sealing part 502, and the sealing part 501 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com