Combined jet flow aeration device

A jet aeration, combined technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of complex production process, high production cost, short service life, etc. The effect of contact area, space saving, high oxygen transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

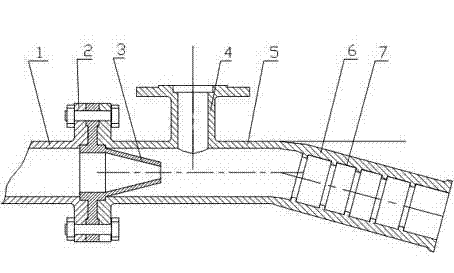

[0016] With reference to the accompanying drawings of the description, a kind of combined jet aeration device of the invention is described in detail below.

[0017] The combined jet aeration device of the present invention is composed of a high-pressure water inlet pipe 1, a jet nozzle 3, and an aeration tee pipe 5, wherein the right end of the high-pressure water inlet pipe 1 and the left end of the aeration tee pipe 5 are provided with Flange 2, the left end of the jet nozzle 3 is provided with a flange 2, the flange of the jet nozzle 3 is arranged between the right end of the high-pressure water inlet pipe 1 and the flange 2 provided at the left end of the aeration tee pipe 5, and the three are connected by bolts Fixed together, the conical nozzle of the jet nozzle 3 extends into the aeration tee pipe 5, and the air intake pipe 4 is arranged on the right side of the flange 2 at the left end of the aeration tee pipe 5, and the lower end of the air intake pipe 4 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com