Palladium or palladium alloy membrane based on wall-flow honeycomb ceramic and preparation method and application thereof

A technology of honeycomb ceramics and palladium alloy membranes, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as small channel diameter, peeling of palladium membranes, and inability to meet the working requirements of palladium composite membranes, and achieve large membranes Area, the effect of increasing hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

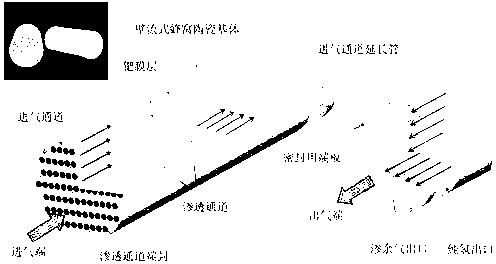

[0031] (1). The wall-flow honeycomb ceramic with square channels was selected as the substrate of the palladium composite membrane. The outer diameter of the substrate was 150 mm, the length was 152.4 mm, and the average pore diameter of the substrate was 3 μm. After cleaning the substrate with commercially available dish soap, rinse with water.

[0032] (2). Use the conventional sol-gel method to modify the inner surface of the matrix pores. The sol composition is 0.5 mol / L Boehmite sol, 5% PVA (polyvinyl alcohol) solution and PEG 400 (polyethylene glycol 400) solution.

[0033] (3). Using conventional SnCl 2 / PdCl 2 The activation method activates the inner surface of the air inlet channel of the wall-flow honeycomb ceramic matrix, in which the sensitization liquid contains SnCl 2 5 g / L, hydrochloric acid 1 ml / L; activation solution contains PdCl 2 0.2 g / L, hydrochloric acid 1 ml / L. First dip in the sensitizing solution and rinse with water, then dip in the activation s...

Embodiment 2

[0038] (1). The wall-flow honeycomb ceramic with circular channels is selected as the substrate of the palladium composite membrane, such as figure 2 As shown, the outer diameter of the substrate is 90 mm, the length is 150 mm, and the average pore diameter of the substrate is 0.2 μm. After cleaning the substrate with commercially available dish soap, rinse with water.

[0039] (2). Using conventional SnCl 2 / PdCl 2 The activation method activates the inner surface of the air intake channel of the wall-flow honeycomb ceramics, in which the sensitizing liquid contains SnCl 2 5 g / L, hydrochloric acid 1 ml / L; activation solution contains PdCl 2 0.2 g / L, hydrochloric acid 1 ml / L. First dip in the sensitizing solution and rinse with water, then dip in the activation solution, and finally dip in dilute hydrochloric acid. Repeat this operation 5 times.

[0040] (3). Put the activated substrate into the plating solution to start electroless plating. The composition of the pla...

Embodiment 3

[0045] (1). The wall-flow honeycomb ceramic with circular channels is selected as the substrate of the palladium composite membrane. The outer diameter of the substrate is 90 mm, the length is 150 mm, and the average pore diameter of the substrate is 3 μm. After cleaning the substrate with commercially available dish soap, rinse with water.

[0046] (2). Use the conventional sol-gel method to modify the inner surface of the matrix pores. The sol composition is 0.5 mol / L Boehmite sol, 5% PVA (polyvinyl alcohol) solution and PEG 400 (polyethylene glycol 400) solution.

[0047] (3). Using conventional SnCl 2 / PdCl 2 The activation method activates the inner surface of the air inlet channel of the wall-flow honeycomb ceramic matrix, in which the sensitization liquid contains SnCl 2 5 g / L, hydrochloric acid 1 ml / L; activation solution contains PdCl 2 0.2 g / L, hydrochloric acid 1 ml / L. First dip in the sensitizing solution and rinse with water, then dip in the activation solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com