Method and device for forming open bottoms on end regions of tubular bag bodies

An end area, bag body technology, used in transportation and packaging, envelope/bag manufacturing machinery, packaging, etc., can solve problems such as difficulty in reprocessing the bottom of the bag, achieve high quality and shape stability, and improve the effect of precise definition

Active Publication Date: 2013-06-12

STARLINGER & CO GMBH

View PDF10 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this known device, the corner flanges are formed together by turning over a bottom side cover, but due to geometrically uncertain initial conditions, do not always have the desired precise shape, so that by positioning the valve plate The inclusion of the bottom side flaps and the connection to the bottom flap also make reprocessing of the bottom of the bag difficult

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

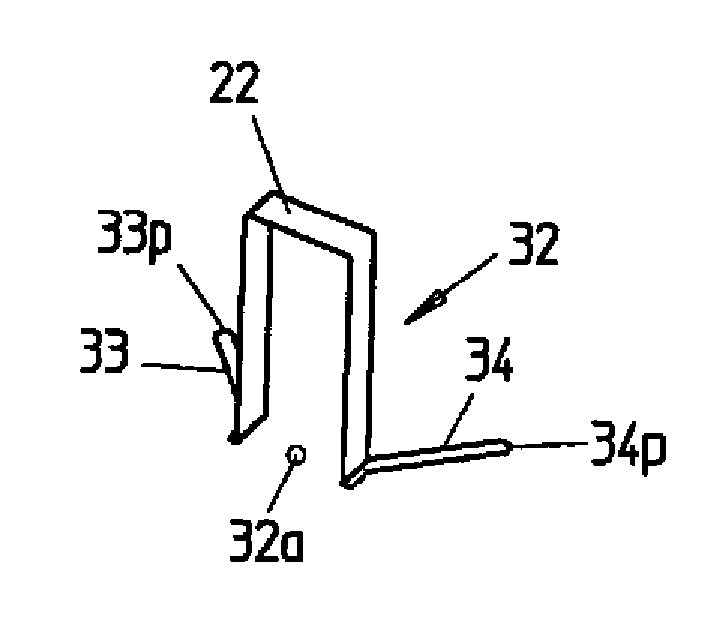

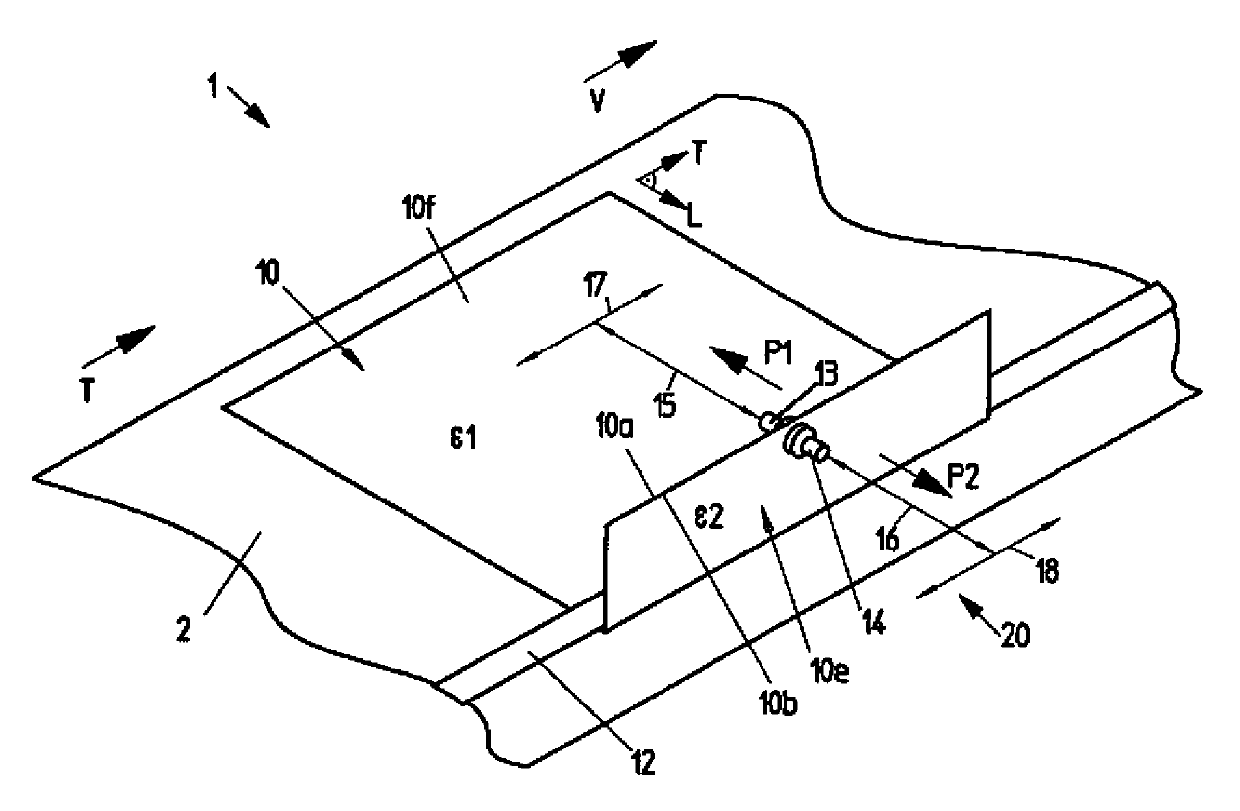

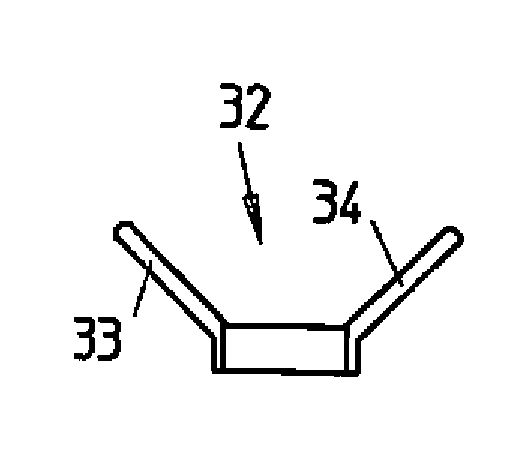

In a device (1) for forming an open bottom in an end region (10e) of a tubular bag body (10), the bag bodies (10) are transported in a flat manner in a transporting direction (T) transverse to the bag body longitudinal extension (L) at a transporting speed (V), and the end regions are opened with an opening device (20). A widening tool is introduced into the opened end regions (10e) of the bag bodies during their transportation on the transporting device and moved in the transporting direction (T) at a speed (V1R) that is increased relative to the transporting speed (V) until front contour points (23p, 24p; 33p, 34p) of said tool run against the inner face of the bag body on the front part (10v) of the opened end region. Said tool widens the front part (10v) into a front corner flap (10j) in the form of an isosceles triangle. The widening tool (21, 30, 32) is moved out of the front corner flap (10j) by slowing of the movement of said tool with respect to the transporting speed (V) after formation of the corner flap (10j). The corner flap is pressed with a pressing device (28, 35, 36).

Description

technical field The invention relates to a method and a device for forming an open bottom at the end region of a tubular bag body, which is preferably produced from a fabric made of stretched plastic tape, wherein the bag The body is transported lying flat at a transport speed in a transport direction transverse to its longitudinal extent, and the end region of the tubular bag body to be folded is opened during transport. Background technique Box bags (Kastensack), also known as cross-bottom bags (Kreuzbodensack) are bags of square configuration, which are manufactured in bag-forming equipment (by providing a tubular bag body whose open end regions are folded into a cross-bottom panel) . The bag is guided through the forming device lying on its back, so that the two layers of the tubular bag rest against each other. For the bottom formation, the two layers are separated from each other at the end region of the tubular bag body and one of the two layers is folded in half by...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B31B29/00

CPCB31B70/00B31B70/52B31B2150/00B31B2150/0014B31B2160/102B31B2160/20B31B2160/10

Inventor H.格里尔

Owner STARLINGER & CO GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com