Method for preparing three-dimensional spherical anatase type TiO2 photo-anode

An anatase type, photoanode technology, applied in the field of solar cell photoanode, can solve the problems of long preparation time, expensive, toxic, etc., and achieve the effects of obvious performance improvement, short operation time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of three-dimensional anatase TiO by low temperature hydrothermal method 2 nanosphere

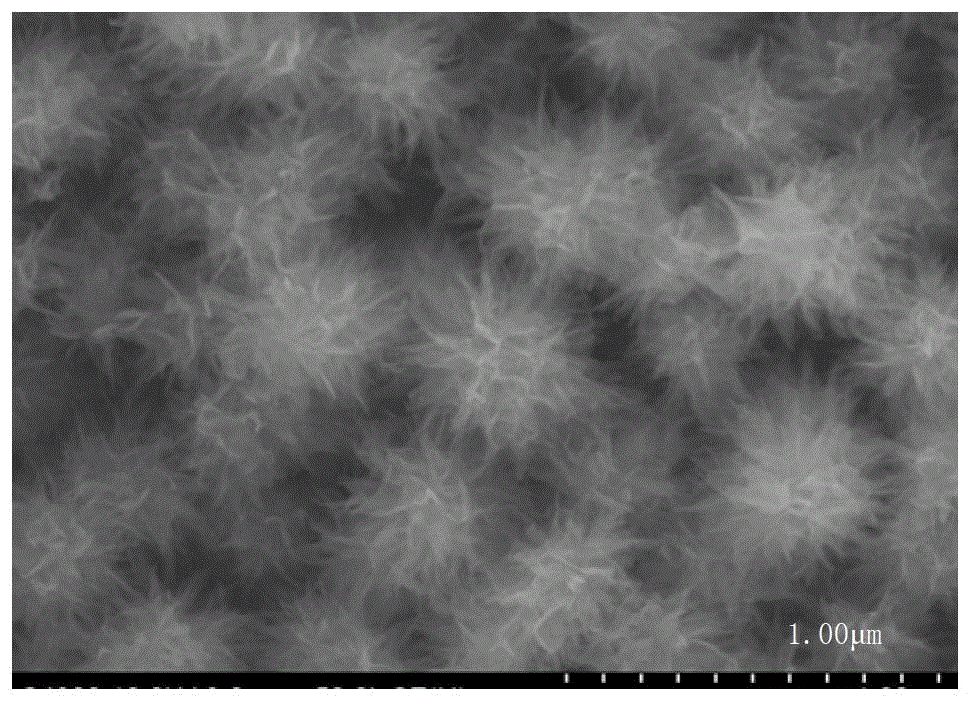

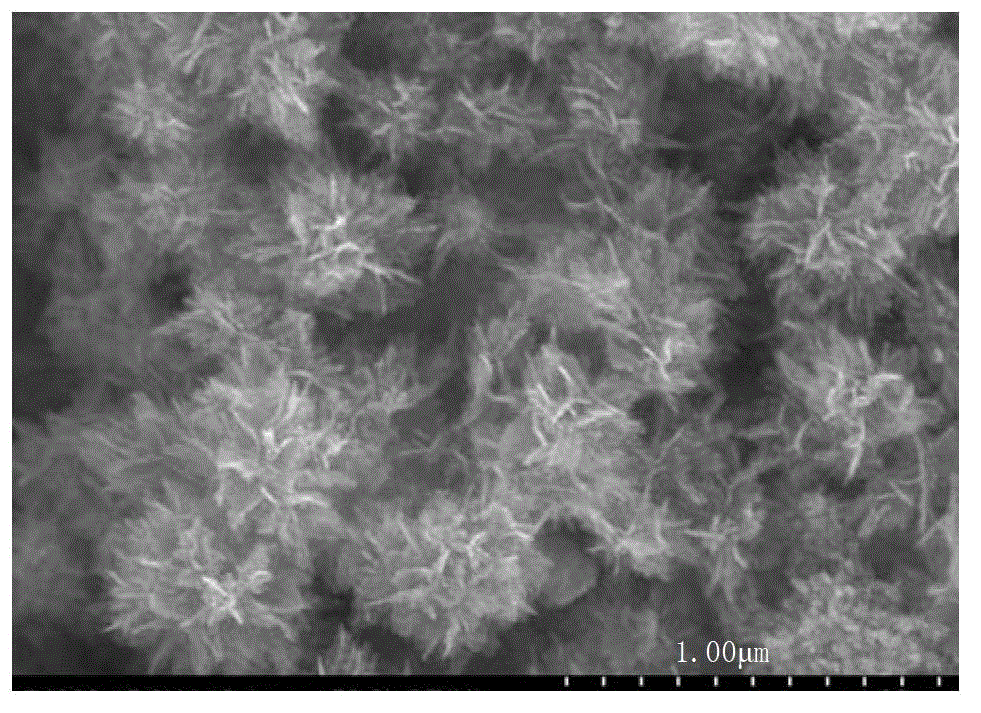

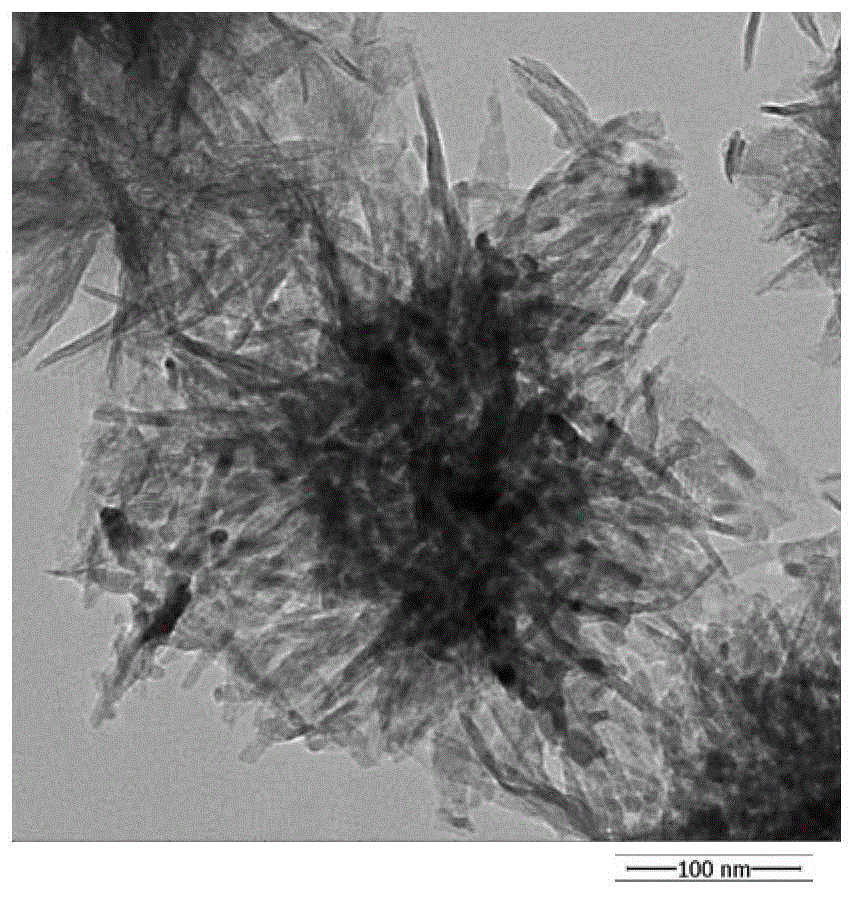

[0035] Prepare 30mL reaction aqueous solution, this solution contains 0.3M NaOH, 15wt%H 2 o 2 , and then wash a piece of titanium and place it in the above solution, and seal it in a hydrothermal kettle, react at 80°C for 1 hour, and cool at room temperature to obtain a light yellow precipitate, which is obtained by washing and filtering with deionized water and 0.1M hydrochloric acid solution respectively. Pale yellow precipitate, finally dried at 60°C and air calcined at 450°C for 2h, can get three-dimensional TiO with high surface area 2 nanospheres. Such as figure 1 As shown, the diameter of nanospheres before high-temperature calcination is about 500nm, and they are assembled by many extremely thin ribbon units, while figure 2 showed that after high-temperature calcination, these ribbon-like units break into smaller sheets, image 3 The TEM images also echoe...

Embodiment 2

[0043] Prepare 30mL reaction aqueous solution, this solution contains 0.3M NaOH, 15wt%H 2 o 2 , and then wash a piece of titanium and place it in the above two solutions, and seal it in a hydrothermal kettle, react at 60°C for 2 hours, cool at room temperature, a pale yellow precipitate can be obtained, wash and filter with deionized water and 0.1M hydrochloric acid solution respectively The obtained pale yellow precipitate was finally dried at 60°C for 2h. Such as Figure 17 , when the hydrothermal reaction temperature is lowered from 80 °C in Example 1 to 60 °C, three-dimensional TiO can also be obtained 2 Spherical structure, the difference is that the diameter of the sphere increases from about 500 nm at 80 °C to about 700 nm at 60 °C. It can be seen that under lower temperature conditions, the reaction rate of the system decreases, and larger spherical structures are easy to form.

Embodiment 3

[0045] Prepare 30mL reaction aqueous solution, this solution contains 0.3M NaOH, 15wt%H 2 o 2 , and then wash a piece of titanium and place it in the above two solutions, and seal it in a hydrothermal kettle, react at 100°C for 0.5h, cool at room temperature, and a pale yellow precipitate can be obtained, which is washed with deionized water and 0.1M hydrochloric acid solution respectively The resulting pale yellow precipitate was filtered and finally dried at 60 °C for 2 h. Such as Figure 18 , when the hydrothermal reaction temperature is increased from 80 °C in Example 1 to 100 °C, three-dimensional TiO can also be obtained 2 A spherical structure, except that the diameter of the spheres decreases from about 500 nm at 80°C to about 300 nm at 100°C. It can be seen that under higher temperature conditions, the reaction speed of the system is accelerated, and smaller spherical structures will be formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com