Two-way twistable staggered-comb teeth electrostatic driving variable optical attenuator and manufacture method thereof

An electrostatic drive, optical attenuator technology, applied in the direction of electric solid devices, instruments, circuits, etc., can solve the problems of asymmetric structure, complex process, difficult linear control and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

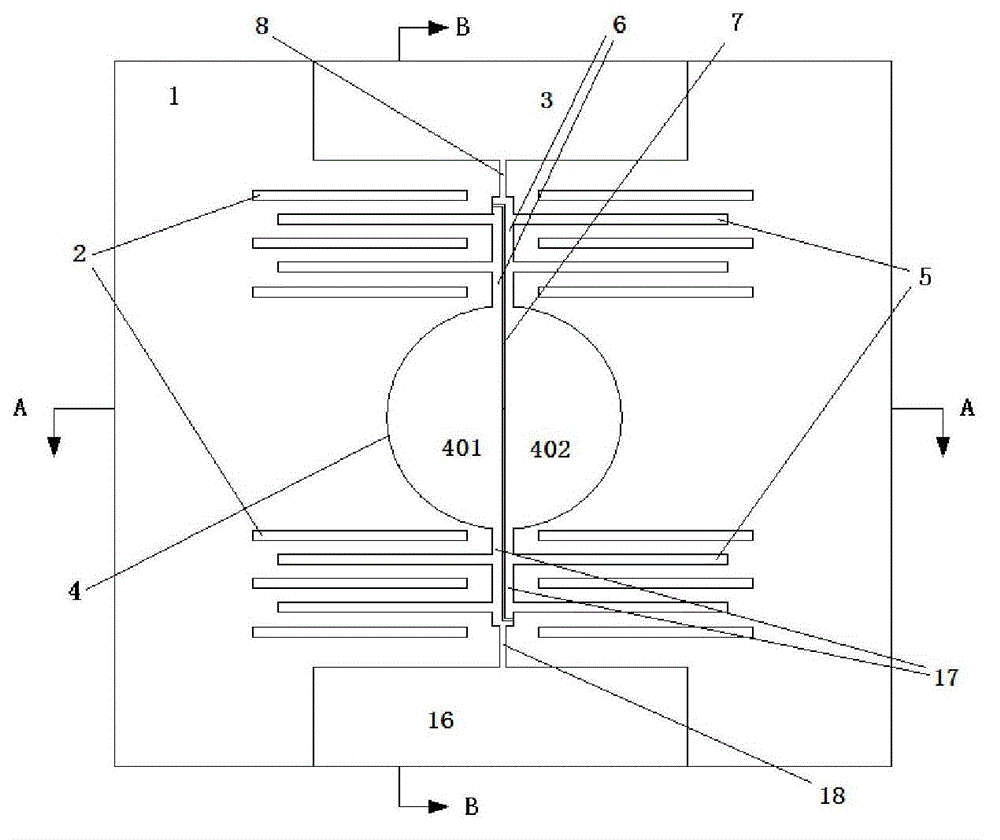

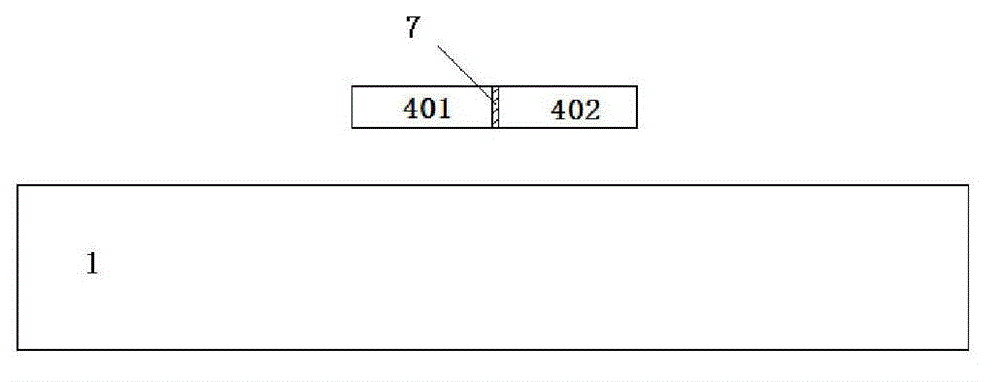

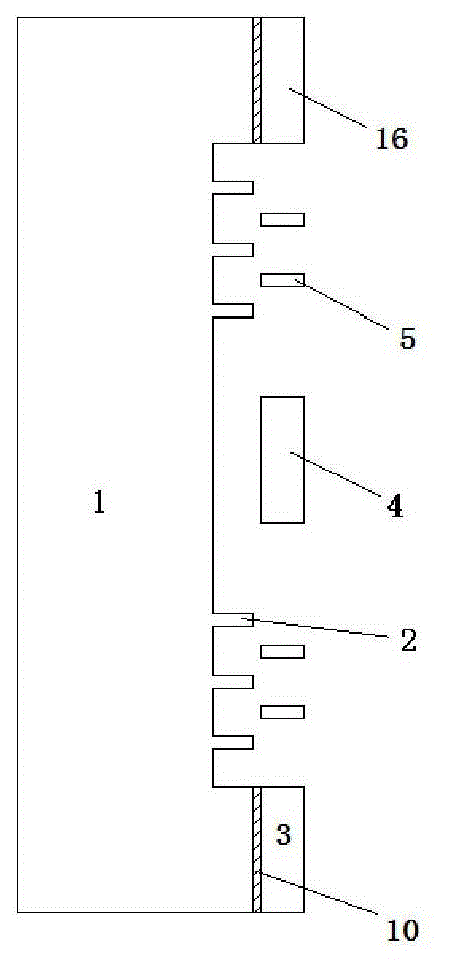

[0027] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1 to Figure 3As shown, the bidirectionally twistable interlaced comb tooth electrostatically driven variable optical attenuator of the present invention includes a substrate 1 with a cavity on the upper part, four fixed comb units 2 fixedly connected in the cavity of the substrate 1, Micromirror 4, four movable comb units 5, first pole 6, insulating medium layer 7, first torsion bar 8, second pole 17, second torsion bar 18, and the first torsion bar above the substrate 1 The active electrode area 3 and the second active electrode area 16 . The first active electrode region 3 and the second active electrode region 16 are fixedly connected to the substrate 1 with the oxide insulating layer 10 respectively. The oxide insulating layer 10 isolates the first active electrode region 3 and the second active electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com