A method for preparing single-layer graphene folded structure with controllable twist angle

A technology of single-layer graphene and twist angle, which is applied in the direction of single-layer graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of low repetition rate, complicated process flow, and strict environmental requirements, and achieve stable folding, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

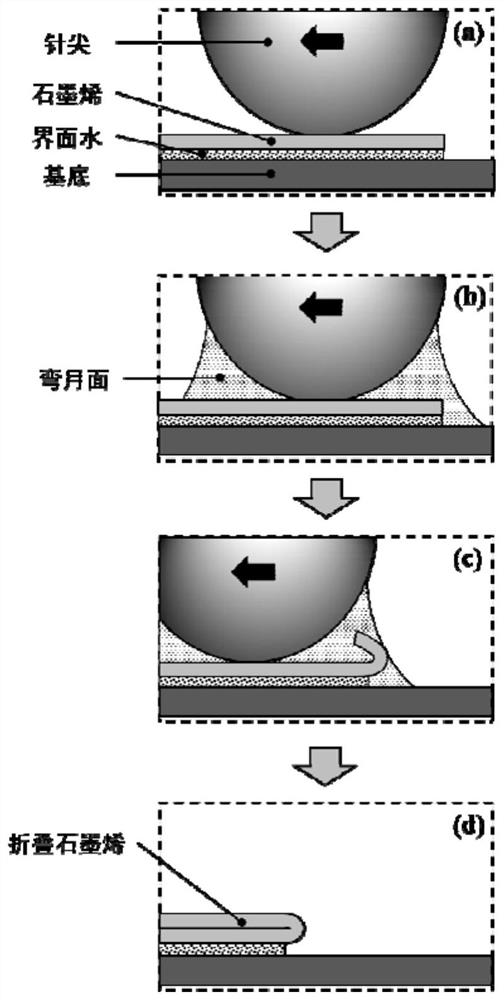

[0037] Such as figure 2 As shown, a method for preparing a single-layer graphene folded structure with controllable torsion angle, the steps are as follows:

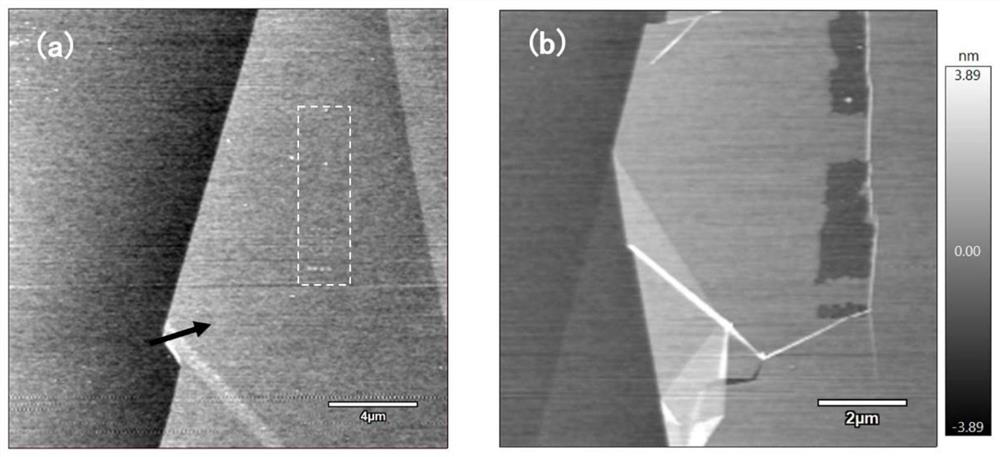

[0038] (1) Using the micromechanical exfoliation method on SiO 2 / Si surface to prepare single-layer graphene, and use the tapping mode of atomic force microscope (AFM) to scan the morphology to obtain the height of single-layer graphene;

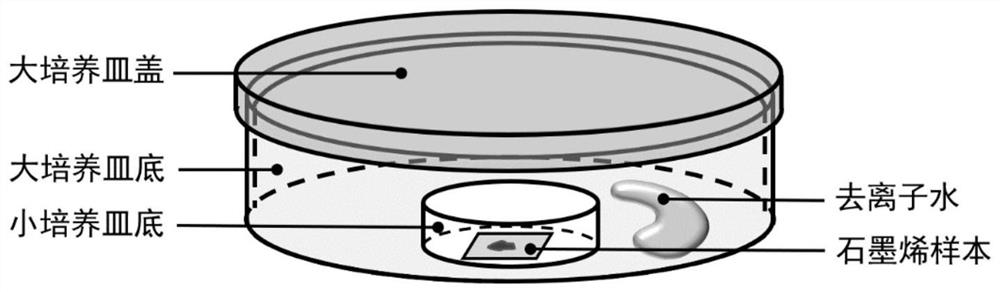

[0039] (2) if figure 1 As shown, the SiO 2 / Si substrate and the single-layer graphene loaded on it are placed in a high-humidity environment with a relative humidity greater than 90% and sealed for two weeks (the specific operation is: the graphene sample is placed in a small petri dish without a lid; the open Place the small Petri dish with the mouth in the large Petri dish, and drop 10-20mL of deionized water into the empty area of the large Petri dish; then cover the lid of the large Petri dish, put it in a sealed bag, seal it, and store it in a cool and dry place for two d...

Embodiment 2

[0048] A method for preparing a single-layer graphene folded structure with controllable twist angle, which is basically the same as in Example 1, except that the probe in step (4) is SiO with a diameter of 5 μm 2 Microsphere tip, and the diameter of the microsphere is 1 / 3 of the maximum size along the direction of the proposed folding motion on the graphene; the size of the load in step (6) is 8nN; the moving speed of the probe in step (7) is 0.3μm / s .

Embodiment 3

[0050] A method for preparing a single-layer graphene folded structure with controllable twist angle, which is basically the same as in Example 1, except that the probe in step (4) is SiO with a diameter of 10 μm 2 A microsphere tip, and the diameter of the microsphere is 1 / 3 of the largest dimension along the direction of the proposed folding motion on the graphene; the size of the load in step (6) is 20nN; the moving speed of the probe in step (7) is 0.1μm / s .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com