A small-angle torsion method for equal-section hollow fan blades based on stress relaxation

A fan blade and stress relaxation technology, which is applied in the field of small-angle torsion of hollow fan blades in cross-section, can solve the problems of difficult to accurately control the torsion angle and the impact of springback, and achieve the effects of stable formed products, avoiding movement, and avoiding springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

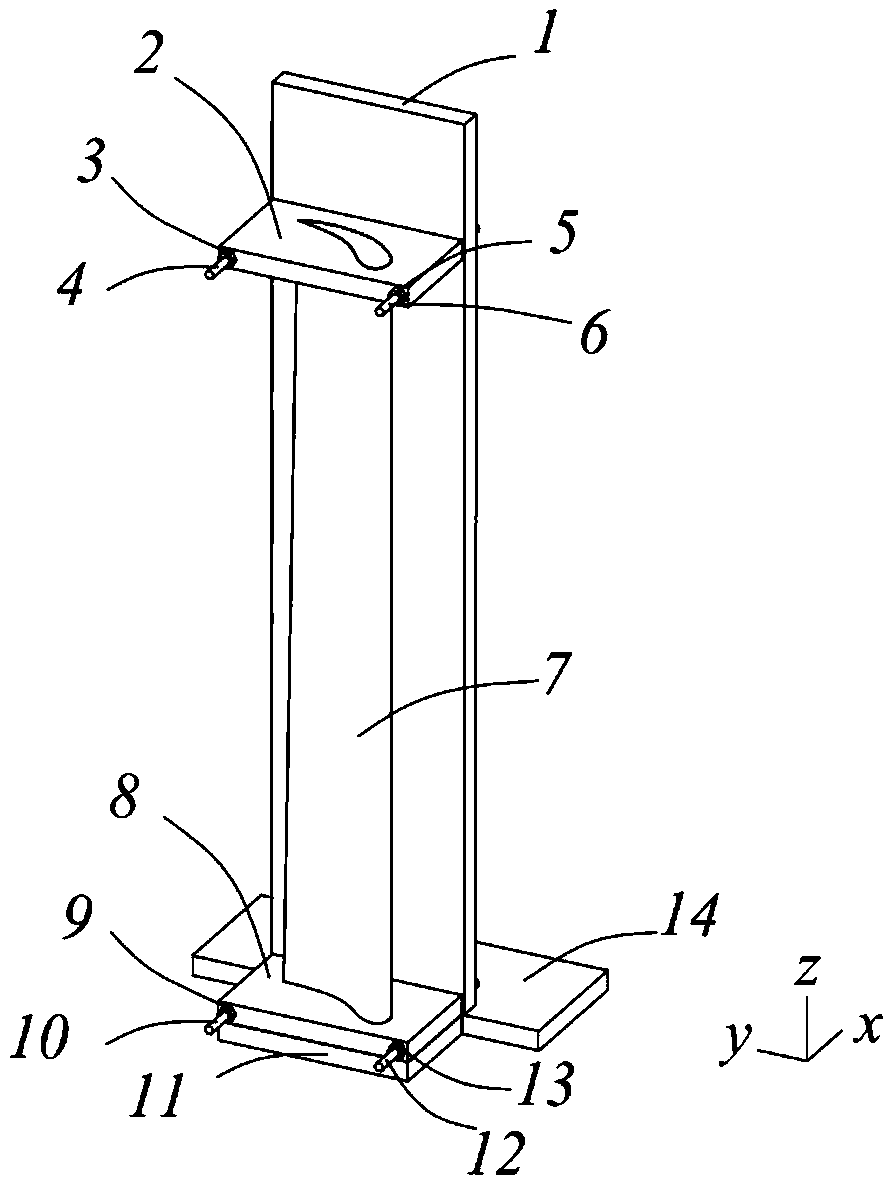

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

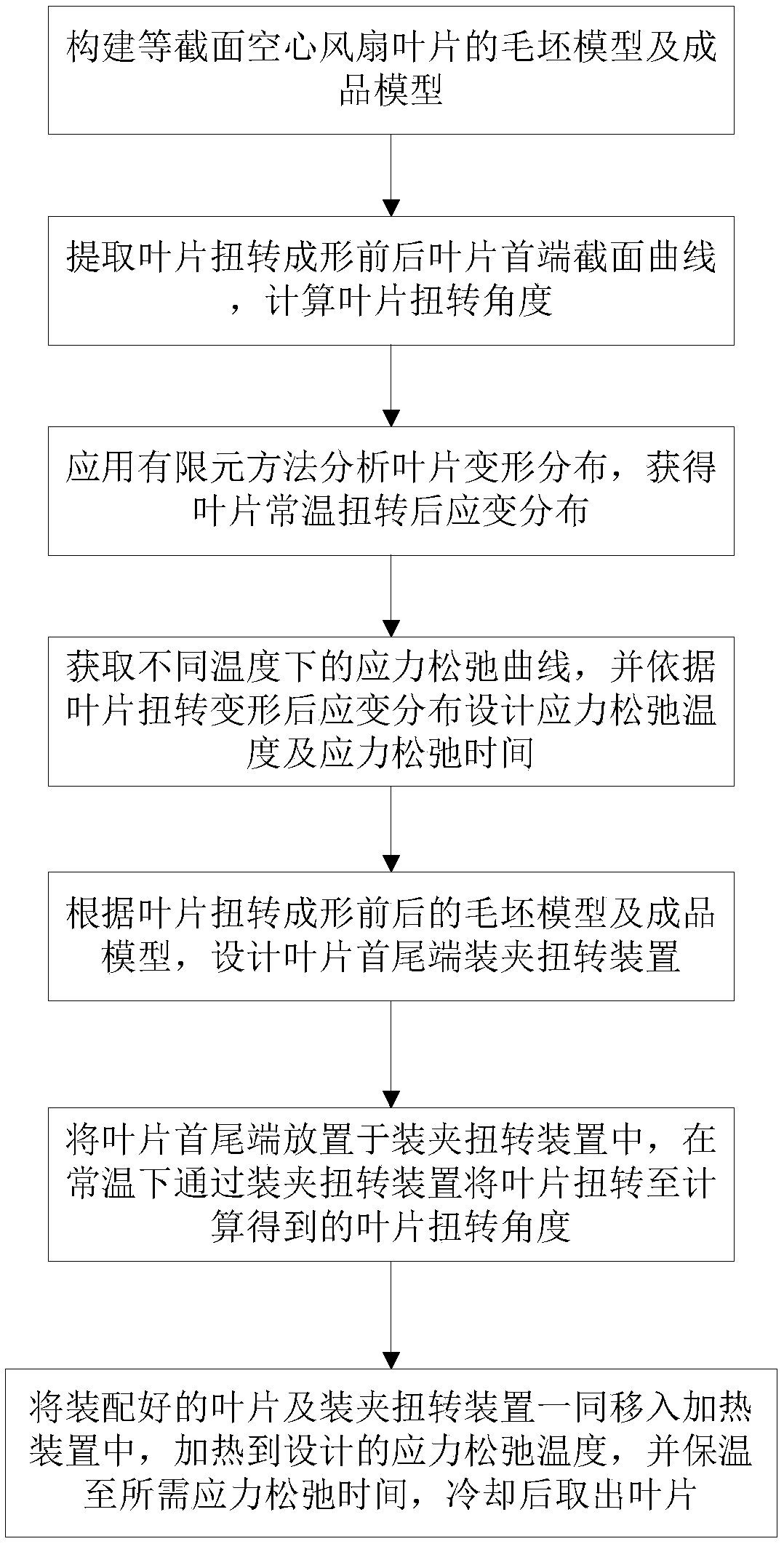

[0028] refer to figure 1 As shown, a small-angle torsion method of equal-section hollow fan blades based on stress relaxation of the present invention includes the following:

[0029] 1) Construct the blank model and finished product model of the hollow fan blade with equal cross-section, that is, the model of the blade before and after forming; see Figure 3a , wherein, 15 is the torsion-shaped front blade, and 16 is the torsion-shaped rear blade.

[0030] 2) Extract the cross-sectional curve of the blade head end before and after the blade torsion forming, and calculate the blade torsion angle; import the blank model and the finished product model of the equal-section hollow fan blade bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com