Test method of plane strain breaking tenacity of aluminum alloy stamp forgings

A fracture toughness and plane strain technology, which can be used in measurement devices, strength properties, instruments, etc., to solve problems such as difficult to measure accurately, and achieve accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the method for testing the plane strain fracture toughness of aluminum alloy die forgings of the present invention is described in detail in conjunction with the examples:

[0020] (i) Preparation of samples

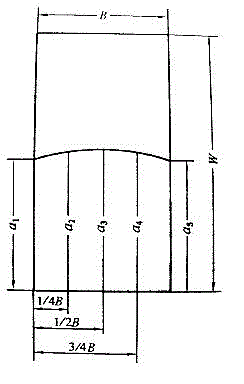

[0021] Process die forgings into compact tensile samples with a thickness of 10mm. Take three samples with the same state during the test, clean the cracks of the samples with acetone and other organic solvents to avoid oil pollution affecting crack growth, number the samples, and use Digital calipers and micrometers measure the width W and thickness B of the sample respectively;

[0022] (ii) Determination of crack length

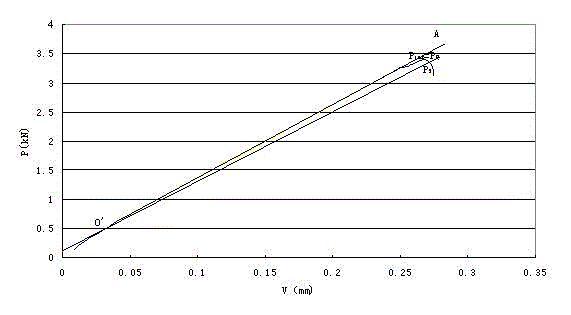

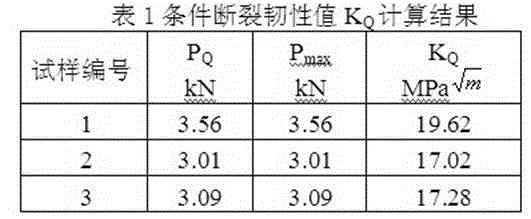

[0023] Install the sample in the fixture, and perform fatigue pre-cracking on the fatigue testing machine. The maximum fatigue load is 3kN, the fatigue stress ratio is 1 / 10, and the fatigue frequency is 10Hz. ) When a / W=0.45~0.55, stop fatigue, break the sample at a rate of 1mm / min, record the breaking force Fm measured on the testing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com