Pressure test and airtight test method of pressed equipment and pressure pipeline system

A technology for pressure pipelines and equipment, applied in the field of pressure equipment and pressure pipeline detection, can solve problems such as detection dead ends, affecting production efficiency, bursting, etc., and achieve the effects of good detection accuracy, good use effect, and fast detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

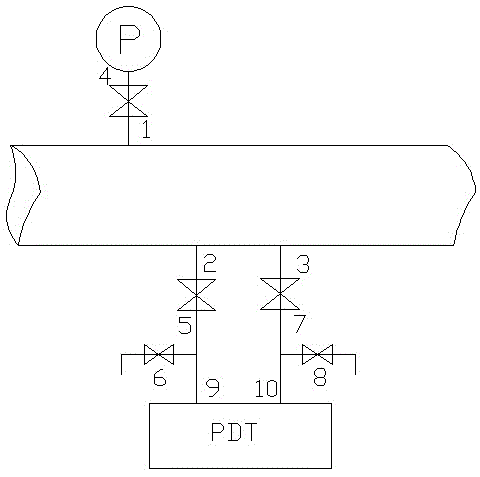

[0010] Embodiments of the present invention: pressure piping system pressure test test airtight method, such as figure 1 As shown, (1) firstly pump the liquid nitrogen and then vaporize it to the pressure required for the pressure test, pressurize it to the pressure piping system to be tested according to the pressure increase rate, and check the sealing points of the equipment pipes and root instruments connected to the main system 1, 2, and 3 to determine its pressure bearing capacity and air tightness, so as to realize integrated air tightness testing; (2) Use a nitrogen cylinder with a pressure gauge It can be determined when nitrogen gas is installed) Off-line detection of the instrument sealing point after the root of each point, 4-10, so as to determine the corresponding air tightness, so as to realize the distributed air tightness detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com