Hydraulic buffering protection device for automobile damper

A technology of hydraulic buffer and protection device, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems such as the reduction and disappearance of the limit buffer function and the reduction of the service life of the shock absorber, so as to avoid abnormality. The effect of noise reduction, impact reduction, and bending resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

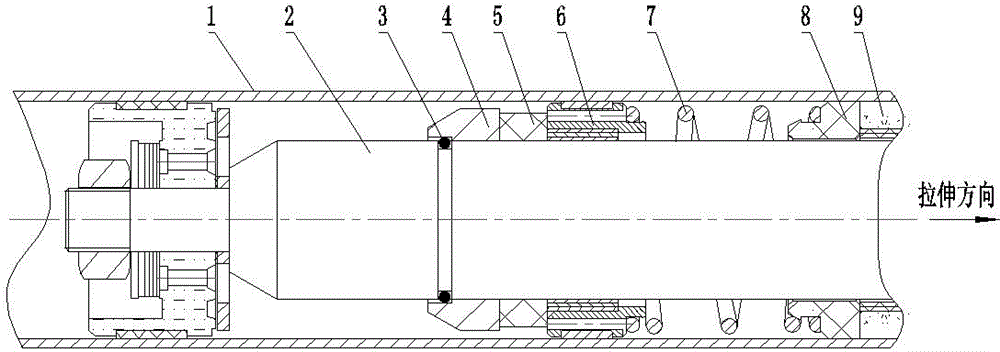

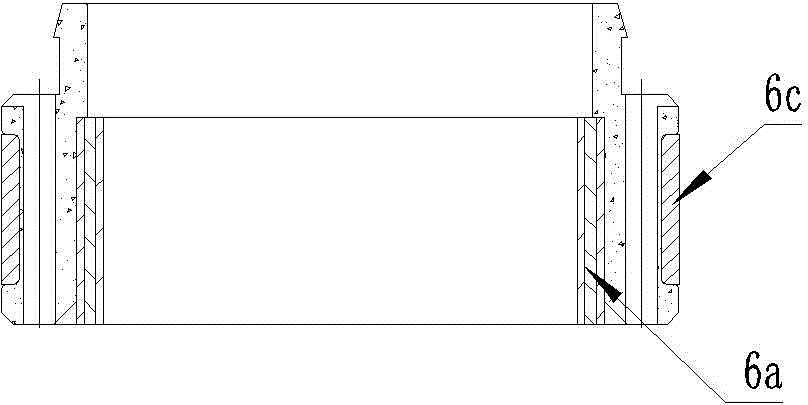

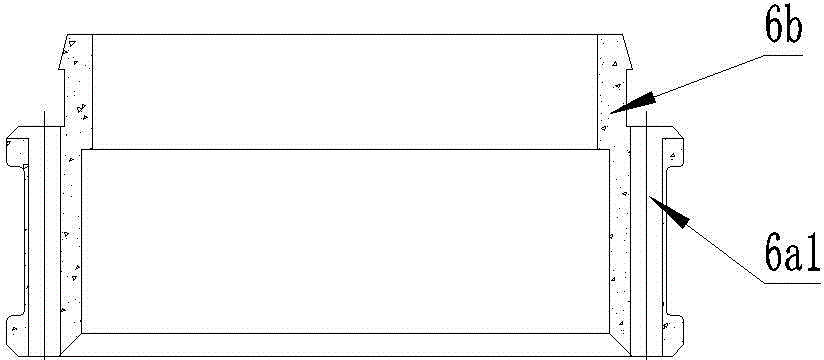

[0012] The following is a detailed description in conjunction with the accompanying drawings: as shown in the figure, the hydraulic buffer protection device for automobile shock absorbers is provided with a piston rod assembly 2 in the working cylinder 1, and a limit clip spring 3 is installed at the limit groove of the piston rod, and The piston rod of the rod assembly 2 is equipped with a limit seat 4, a limit buffer pad 5 and a floating piston assembly 6. The floating piston assembly 6 is composed of a bush 6a, a floating piston 6b and a piston ring 6c; There are several small through holes 6a1, the bush 6a made of three-layer composite material is pressed into the small through hole 6a1 of the floating piston, the floating piston 6b is in clearance fit with the piston rod of the piston rod assembly 2, the piston ring 6c is in contact with the working Cylinder 1 clearance fit, limit cushion 5 and the piston rod of piston rod assembly 2 interference fit, fixed on the end of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com