Liquid-phase distribution self-cleaning device for emulsion liquid pumping plant

An emulsion pumping station and emulsion pump technology are applied in the field of liquid phase distribution self-cleaning devices for emulsion pumping stations, which can solve the problems of large engineering, low reliability, high power consumption, etc., and achieve simple control and prolonged cleaning cycle. , the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

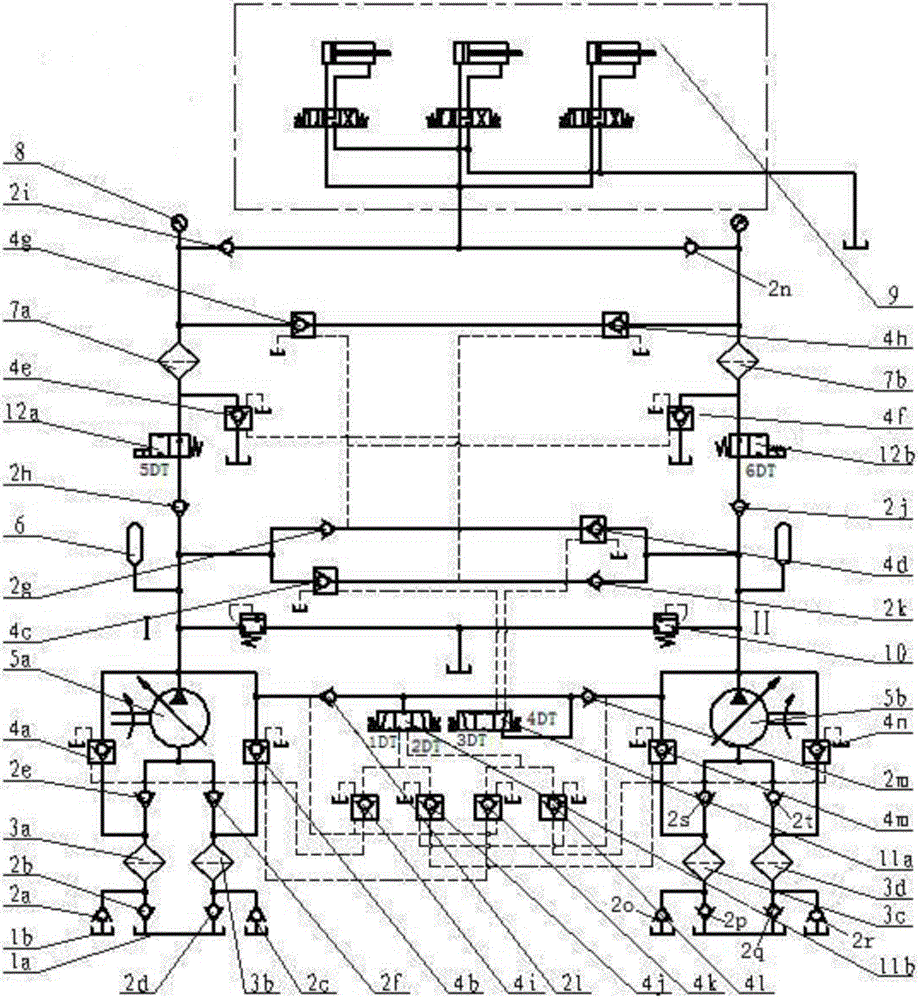

[0027] The present invention will be further explained below in conjunction with the accompanying drawings.

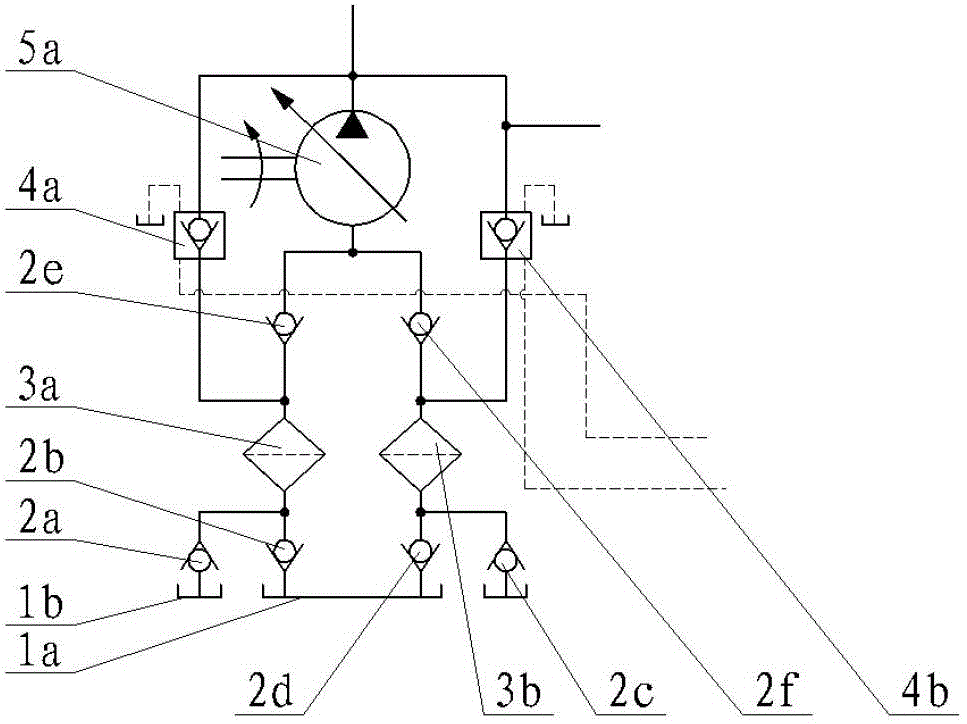

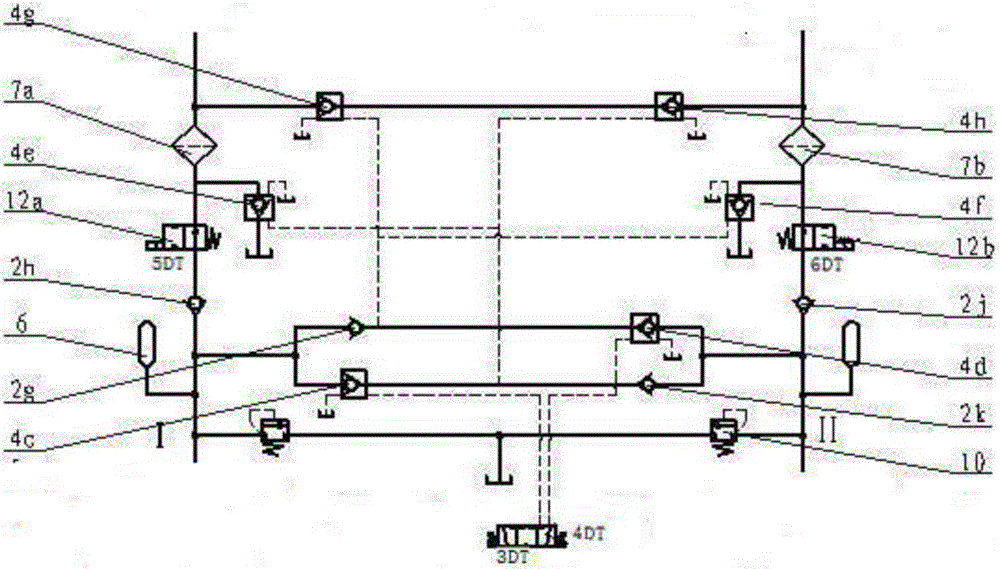

[0028] Such as Figures 1 to 5 As shown, the liquid phase distribution self-cleaning device of the emulsion pump station of the present invention includes an oil tank, a low-pressure filter system, an emulsion pump system, a high-pressure filter system, a bypass valve group and an electromagnetic control valve group. The low pressure filter system includes low pressure filter 1 3a, low pressure filter 2 3b, low pressure filter 3 3c and low pressure filter 4 3d, the emulsion pump system includes emulsion pump 1 5a and emulsion pump 2 5b, and the high pressure filter system includes High pressure filter one 7a and high pressure filter two 7b.

[0029] The liquid inlet of low-pressure filter one 3a is respectively connected with the liquid inlet of one-way valve one 2a and the liquid outlet of one-way valve two 2b, and the liquid inlet of low-pressure filter two 3b is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com