High-intensity gray pig iron inoculator and preparation method thereof

An inoculant and technology for grey cast iron, applied in the field of inoculant for high-strength grey cast iron and its preparation, can solve the problems of inability to improve the strength of grey cast iron, increase the percentage of castings, waste of raw materials, etc., and reduce the sensitivity of tissue wall thickness , The effect of reducing inoculation recession and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

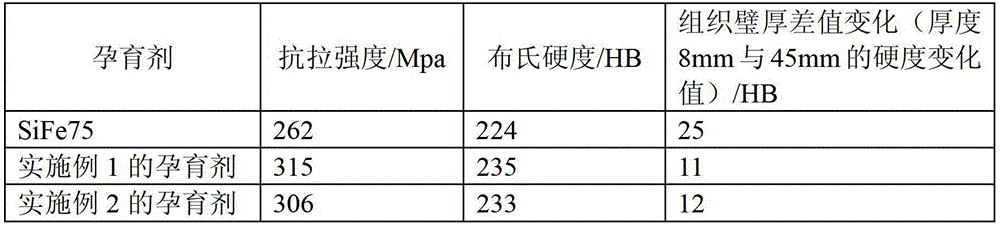

Examples

Embodiment 1

[0010] Proportion (parts by weight): Si: 65-72%, Al: 0.5-1.2%, Zr: 0.5-1.5%, RE: 0.6-1.8%, Mn: 4.0-6.0%, Sn: 0.4-1.2%, C <0.2, S<0.02, P<0.05, the balance is iron and unavoidable impurities.

[0011] Preparation method: Si is provided by ferrosilicon (FeSi75Al1.5, FeSi45Al1.5), RE is provided by rare earth ferrosilicon alloy (FeSiRe26), Mn is provided by ferromanganese, Zr and Sn are provided by metal zirconium and metal tin respectively; mix the above raw materials , Melting, cooling, crushing into 3-8mm particles.

Embodiment 2

[0013] Proportion (parts by weight): Si: 65-72%, Al: 0.5-1.2%, Zr: 0.5-1.5%, RE: 0.6-1.8%, Mn: 4.0-6.0%, Sb: 0.1-0.4%, C <0.2, S<0.02, P<0.05, the balance is iron and unavoidable impurities.

[0014] Preparation method: Si is provided by ferrosilicon (FeSi75Al1.5, FeSi45Al1.5), RE is provided by rare earth ferrosilicon alloy (FeSiRe29), Mn is provided by ferromanganese, Zr and Sb are respectively provided by metal zirconium and metal antimony; mix the above raw materials , Melting, cooling, crushing into 3-8mm particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com