Reorganized mannase, genetically-engineered bacteria of recombined mannose and hydrolyzing preparation mannan oligosaccharide method

A technology of mannanase and genetically engineered bacteria is applied in the fields of recombinant mannanase and genetically engineered bacteria and the preparation of mannose oligosaccharides by hydrolysis, and can solve the problems of low substrate concentration, low hydrolysis efficiency, poor activity, etc. The effect of simplifying processing steps, shortening the process flow, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0192] 1. Construct the recombinant β-mannanase gene according to the first step of the method of the present invention;

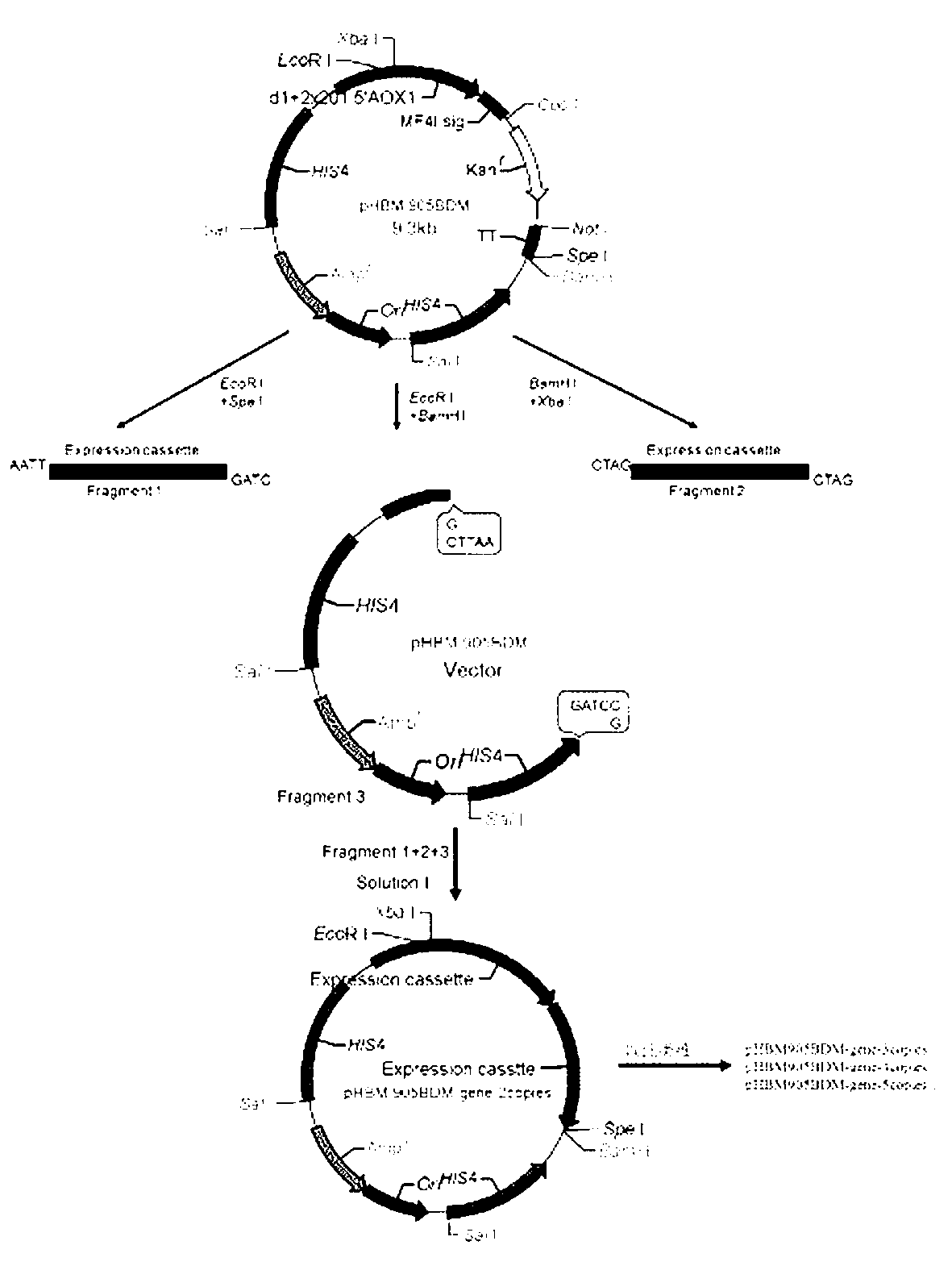

[0193] 2. Construct the recombinant expression vector pHBM905BDM according to the second step of the method of the present invention;

[0194] 3. Digest the pHBM905BDM plasmid sequentially with restriction endonucleases Cop I and Not I to produce a vector with two fixed base single-stranded cohesive ends, and recover the vector from agarose gel; secondly, according to the known man gene sequence , use GeneTool software to design two primers, man-1: 5'GTCA ATGTTGCCAAAGGCTTTCTCAGCCCCATCCACTTCTTTCTAG3' and man-45: 5'GGCCATTAATGGTGATGGTGATGGTGAGCAGAACCGATAGCTGCAACAT3', use primerstar DNA polymerase for PCR amplification, and obtain the man (1.1kb) gene fragment, which is agarose After gel recovery, in the presence of dTTP, treat with T4 DNA polymerase at 12°C for 20 min to generate cohesive ends that match with the pHBM905BDM carrier, and recover fragments. T...

Embodiment 2

[0199] The constructed single-copy and two-copy mannanase recombinant strains were respectively inoculated in 50 mL of BMGY medium, cultured at 28°C and 200 r / min for 48 hours, until OD 600 6-9, centrifuge at room temperature at 5000r / min for 5min to collect the bacteria, then transfer the bacteria to 50mL BMMY medium, culture at 28°C and 200r / min, add methanol once every 12h (addition amount is 0.5% of the medium volume), after induced expression, the expression supernatants were taken at 24h, 48h, and 72h respectively for SDS-PAGE electrophoresis, and the protein expression levels at different time periods were analyzed. (See image 3 ).

Embodiment 3

[0201] Mannan-oligosaccharides were prepared by hydrolyzing mannans with different concentrations using the recombinant mannanase crude enzyme solution obtained in shake flasks in Example 2.

[0202] Raw material: guar gum

[0203] 1) The concentrations of the hydrolyzed substrates are respectively prepared to be 10%, 25%, 30%, and 40%;

[0204] Use tap water at a temperature of 50-55°C as a solvent, add an appropriate amount of guar gum, stir, and prepare 100ml of reaction solutions with substrate concentrations of 10%, 25%, 30%, and 40%, and then press the substrate and enzyme Solution ratio 1g: 20ul, add 200ul, 500ul, 600ul, 800ul of crude enzyme solution respectively. No need to adjust pH.

[0205] The hydrolysis times were about 10, 30, 45, 60 minutes, respectively.

[0206] The reaction solution is centrifuged to remove residues, the supernatant is taken for filtration, ultrafiltration, and vacuum spray drying to obtain the finished mannooligosaccharide.

[0207] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com