Preparation method of purple sweet potato wine

A technology of purple sweet potato and Saccharomyces cerevisiae, which is applied in the field of wine making, can solve the problem of destroying purple sweet potato nutrition, aroma substances and physiological functional substances, reducing the quality of purple sweet potato wine, nutrition and health function value, and destroying the stability of anthocyanins in purple sweet potato To achieve the effect of obvious characteristic flavor, high transparency and clarity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of embodiment 1 purple sweet potato wine

[0027] (1) The preparation method is as follows:

[0028] 1) Fragmentation of purple sweet potatoes: grind the peeled purple sweet potatoes with a colloid mill to obtain purple sweet potato pulp;

[0029] 2) Saccharification: Add glucoamylase to purple sweet potato pulp, and saccharify at 70°C for 30 minutes to obtain purple sweet potato saccharification liquid;

[0030] 3) Fermentation: In purple sweet potato saccharification solution, press 1×10 3 The ratio of cfu / L is inserted into the activated fruit wine yeast, fermented at 10-35°C for 15 days, and filtered to obtain the filtrate;

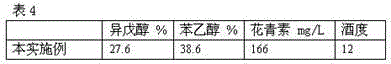

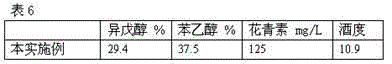

[0031] 4) Aging: aging the obtained filtrate for 180 days at 10-20°C to obtain purple sweet potato wine with strong fruit wine aroma and sweet potato aroma, bright color, rich nutrition and high anthocyanin content. Alcohol 9.4 o , Anthocyanin content: 143mg / L.

[0032] (2) Comparative test

[0033] Using the tra...

Embodiment 2

[0036] The preparation method of embodiment 2 purple sweet potato wine

[0037] (1) Preparation method

[0038] 1) Fragmentation of purple sweet potatoes: grind the peeled purple sweet potatoes with a colloid mill to obtain purple sweet potato pulp;

[0039] 2) Saccharification: Inject pre-activated Aspergillus niger into purple sweet potato pulp, and saccharify at 35°C for 3 days to obtain purple sweet potato saccharification liquid;

[0040] 3) Fermentation: In purple sweet potato saccharification solution, press 1×10 7 Insert activated fruit wine yeast at the ratio of cfu / L, such as commercially available Angel wine yeast, ferment at 35°C for 1 day, and filter to obtain the filtrate;

[0041] 4) Aging: aging the obtained filtrate for 180 days at 10-20°C to obtain purple sweet potato wine with strong fruit wine aroma and sweet potato aroma, bright color, rich nutrition and high anthocyanin content. Alcohol 11.2 o , Anthocyanin content: 116mg / L.

[0042] Aspergillus n...

Embodiment 3

[0047] The preparation method of embodiment 3 purple sweet potato wine

[0048] (1) Preparation method

[0049] 1) Fragmentation of purple sweet potatoes: grind the peeled purple sweet potatoes with a colloidal mill to obtain purple sweet potato pulp;

[0050] 2) Saccharification: add koji to purple sweet potato pulp, and saccharify at 10°C for 3 days to obtain purple sweet potato saccharification liquid;

[0051] 3) Fermentation: In purple sweet potato saccharification solution, press 1×10 7 The ratio of cfu / L was inserted into activated Saccharomyces cerevisiae, and fermented at 10-35°C for 5 days; filtered to obtain the filtrate;

[0052] 4) Aging: aging the obtained purple sweet potato wine at 10-20°C for 150 days to obtain a purple sweet potato wine with rich fruit wine aroma and sweet potato aroma, bright color, rich nutrition and high anthocyanin content. Alcohol 12.1 o , Anthocyanin content: 150mg / L.

[0053] (2) Comparative test

[0054] Using the traditional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com