Multi-nozzle entrained-flow bed gasification furnace

A gasifier and entrained bed technology, which is applied in the field of multi-nozzle entrained bed gasifiers, can solve the problems of unreliable operation, burn-through of downcomers, and high investment costs, and achieves improved residence time, improved stability and reliability, and improved stability and reliability. The effect of simplifying the device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

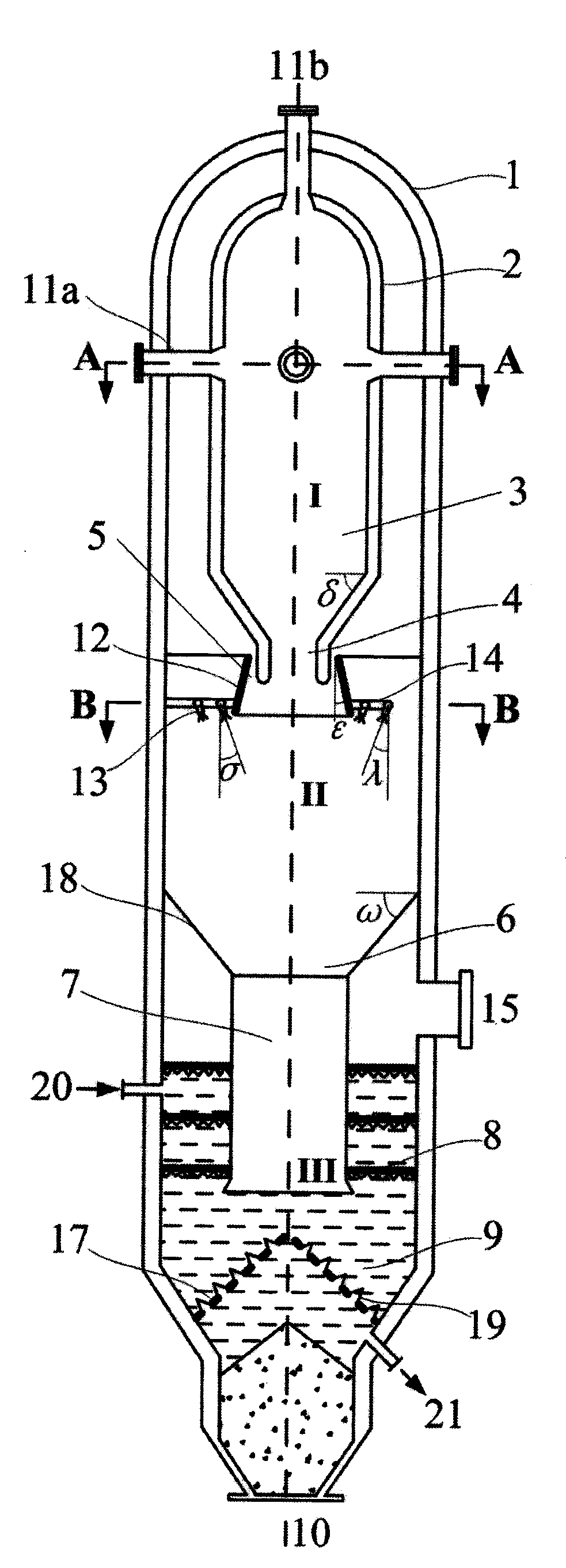

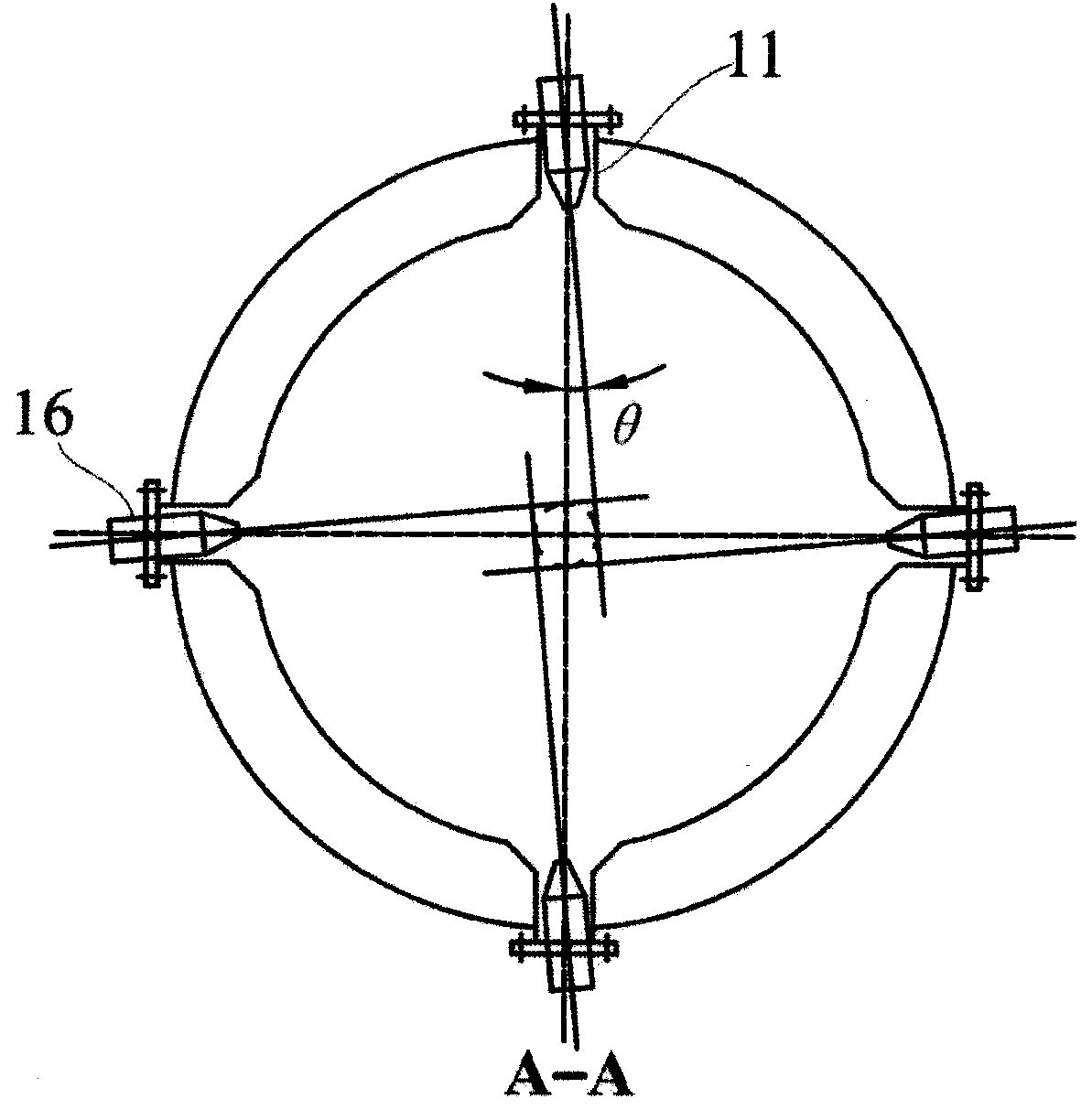

[0044] A set of dry coal powder pressurized multi-nozzle entrained flow gasifier with a daily processing capacity of 3,000 tons of coal. The inner diameter of the shell of the gasification reaction chamber (that is, the wall 2 of the gasifier) is 3850mm, and the inner diameter of the lower slag port of the gasifier is 4 1100mm. A layer of four side process burners 16 is evenly arranged on the upper side of the gasification furnace body. The plane of the side process burners is perpendicular to the axis of the gasification reaction chamber, and the radial deflection angle θ is 4.5°. The four side process burners 16 A total of 100% pulverized coal, 100% water vapor and 100% pure oxygen are injected, and the top burner chamber 11b is used as an ignition / start-up burner.

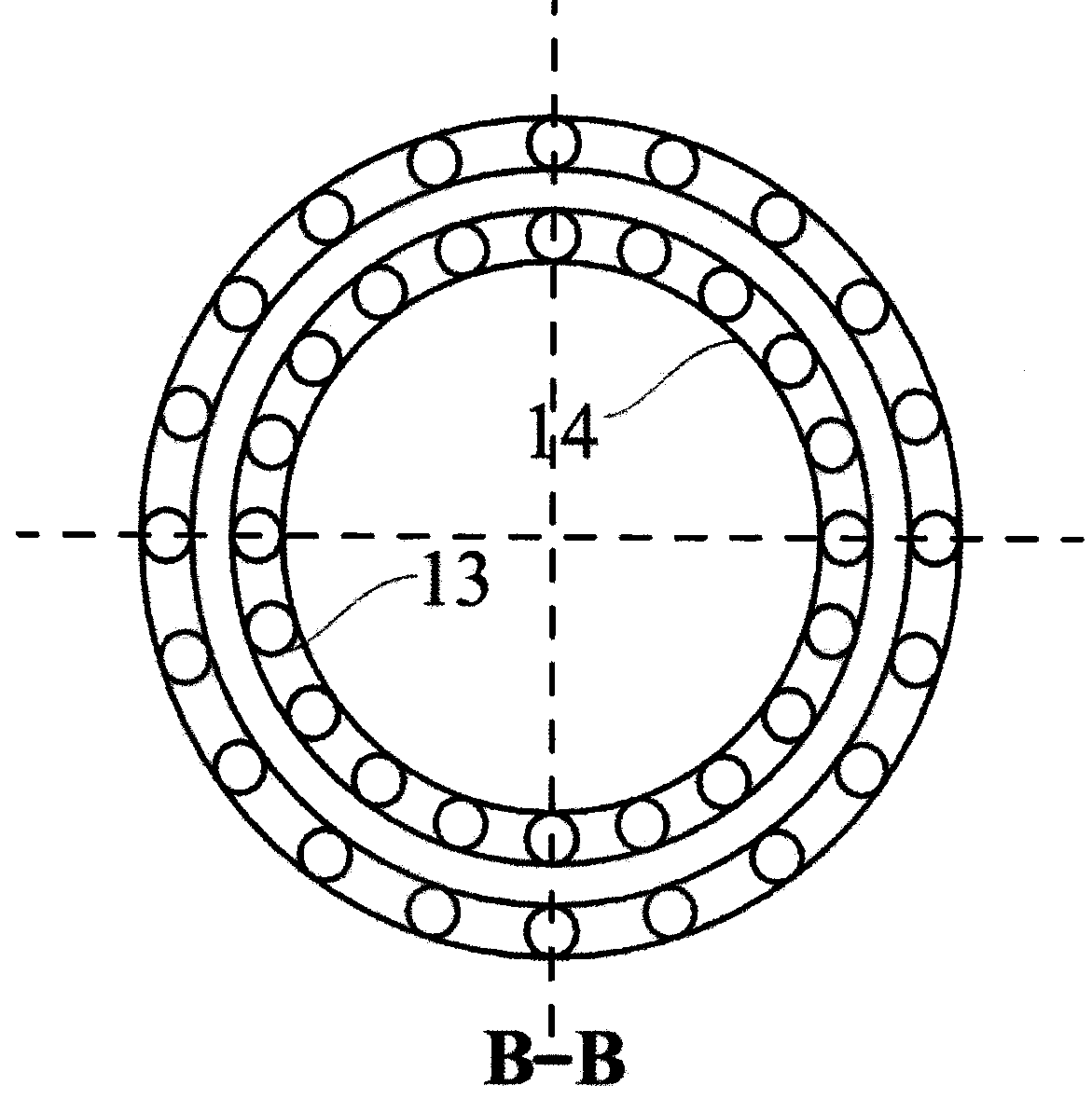

[0045] The cylinder diameter of the syngas quenching conversion chamber is 4800 mm. There is one layer of quenching ring 14. 128 quenching nozzles 13 are evenly arranged along the quenching ring 14. Liquid wat...

Embodiment 2

[0073] A set of coal-water slurry pressurized multi-nozzle entrained gasifier with a daily processing capacity of 3000 tons of coal. The inner diameter of the gasifier body (namely the gasifier wall 2) is 4000mm, and the inner diameter of the lower slag port 4 of the gasifier is 1000mm. A layer of four side process burners 16 is evenly arranged on the upper side of the gasification furnace body. The plane of the side process burners is perpendicular to the axis of the gasification reaction chamber, and the radial deflection angle θ is 1.8°. The four side process burners 16 100% coal water slurry and 100% pure oxygen are injected into the process burner in the top burner chamber 11b.

[0074] The cylinder diameter of the syngas quenching conversion chamber is 4800 mm. The quenching ring 14 is provided with a layer. The quenching nozzles 13 are evenly arranged along the quenching ring 14. There are 128 layers. The included angle λ is 30°, the second included angle α of radial in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com