Diethylene glycol ferrous alkoxide with three-dimensional pattern multi-stage structure and preparation method thereof

A diethylene glycol ferrous alcohol, pattern technology, applied in ether preparation, dehydration of hydroxyl-containing compounds to prepare ether, organic chemistry, etc., can solve problems such as environmental pollution, high synthesis cost, unfavorable production and application, and achieve environmental friendliness, The effect of the simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

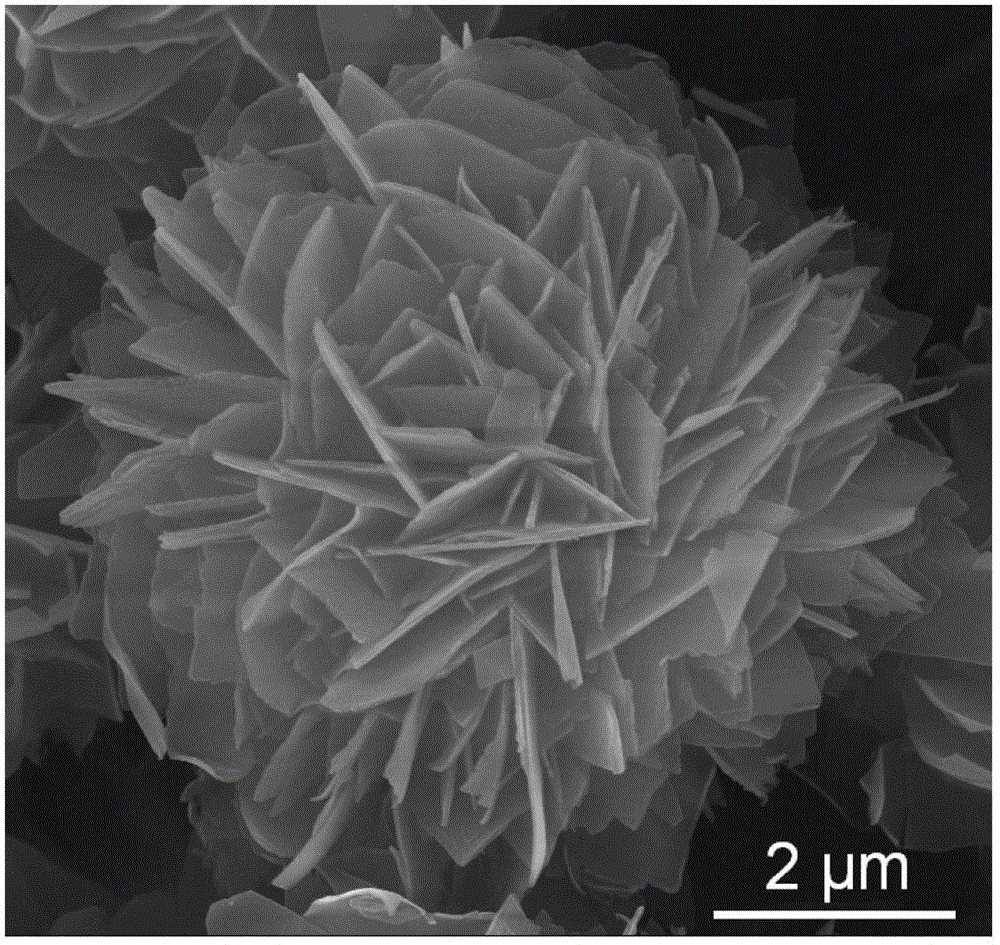

[0016] 1.35 g (0.005 mol) FeCl 3 ·6H 2 O and 3.60 g (0.0265 mol) CH 3 COONa·3H 2 O is placed in the 1000mL there-necked bottle, adds 400mL ethylene glycol, puts the there-necked bottle into 50 o Electric stirring in C water bath for 2 h to obtain a transparent yellow solution; transfer the above yellow solution to a 500mL Teflon stainless steel reaction kettle, seal it, and place it at 200 o In C oven, the yellow solution in the reaction kettle was reacted under autogenous pressure for 8 hours, and after the reaction was completed, the reaction kettle was cooled to room temperature with tap water; the green precipitate obtained by centrifugation was washed three times with absolute ethanol, and then the o C dried in an oven for 12 hours, stored in a desiccator, and the product was diethylene glycol ferrous alkoxide with three-dimensional pattern and hierarchical structure.

Embodiment 2

[0018] 1.35 g (0.005 mol) FeCl 3 ·6H 2 O and 3.60 g (0.0265 mol) CH 3 COONa·3H 2 O is placed in the 1000mL there-necked bottle, adds 400mL ethylene glycol, puts the there-necked bottle into 40 o Electric stirring in C water bath for 2.5 h to obtain a transparent yellow solution; transfer the above yellow solution to a 500mL Teflon stainless steel reaction kettle, seal it, and place it at 200 o In the C oven, the yellow solution in the reaction kettle was reacted for 8 hours under autogenous pressure. After the reaction, the reaction kettle was cooled to room temperature with tap water; the green precipitate obtained by centrifugation was washed three times with absolute ethanol, and then the o C dried in an oven for 12 hours, stored in a desiccator, and the product was diethylene glycol ferrous alkoxide with three-dimensional pattern and hierarchical structure.

Embodiment 3

[0020] 1.35 g (0.005 mol) FeCl 3 ·6H 2 O and 3.60 g (0.0265 mol) CH 3 COONa·3H 2 O is placed in the 1000mL there-necked bottle, adds 400mL ethylene glycol, puts the there-necked bottle into 30 o Electric stirring in C water bath for 3h to obtain a transparent yellow solution; transfer the above yellow solution to a 500mL Teflon stainless steel reaction kettle, seal it, and place it at 200 o In the C oven, the yellow solution in the reaction kettle was reacted for 8 hours under autogenous pressure. After the reaction, the reaction kettle was cooled to room temperature with tap water; the green precipitate obtained by centrifugation was washed three times with absolute ethanol, and then the o C dried in an oven for 12 hours, stored in a desiccator, and the product was diethylene glycol ferrous alkoxide with three-dimensional pattern and hierarchical structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com