Automatic sheet transmission tension adjustment device and sheet post-processing system

An automatic adjustment and processing system technology, applied in the direction of transportation and packaging, winding strips, thin material processing, etc., can solve problems such as paper breaking, speed difference fluctuations, and affecting production efficiency, so as to achieve stable tension, eliminate influence, and improve The effect of processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

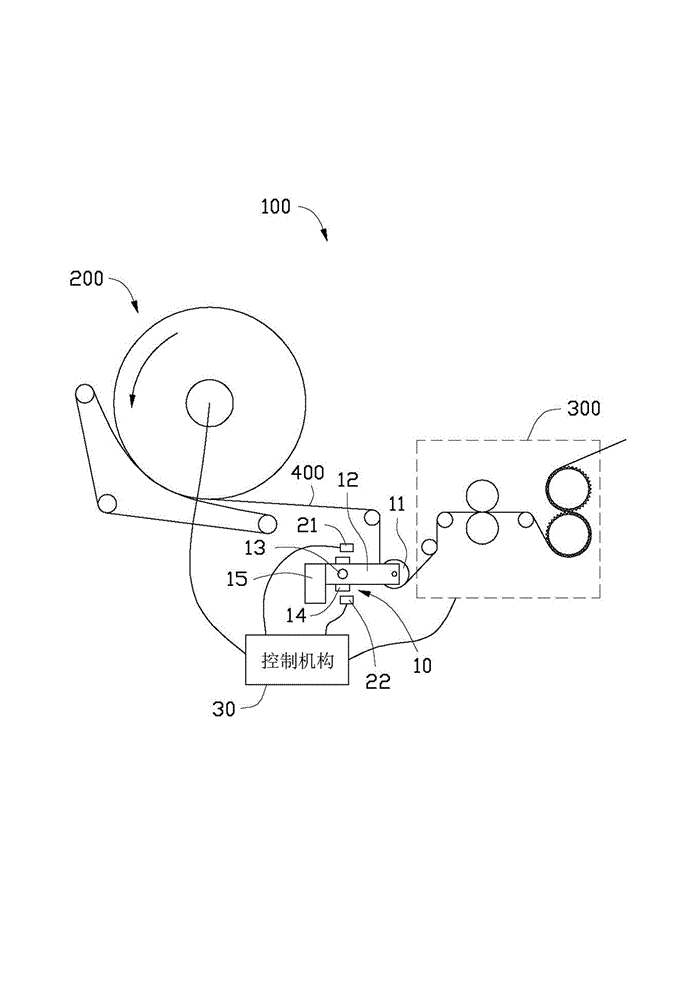

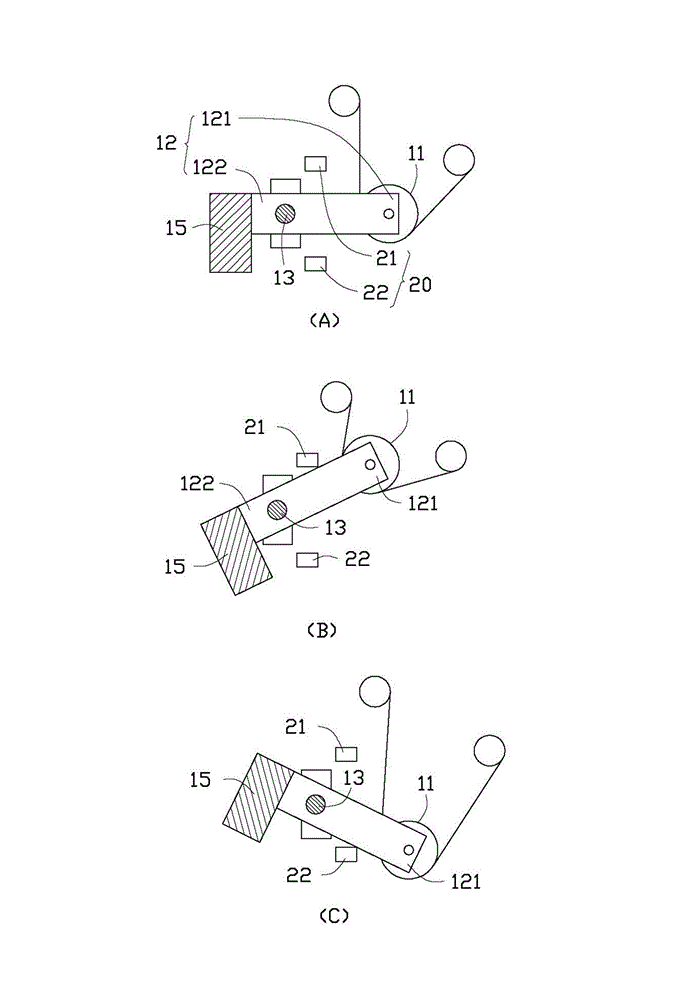

[0017] Such as figure 1 and figure 2 As shown, the sheet conveying tension automatic adjustment device 100 provided by the embodiment of the present invention is used to adjust the The transmission stroke of the sheet between the sheet unwinding device 200 and the sheet post-processing device 300, so that the sheet always maintains tension when it is transported between the sheet unwinding device 200 and the sheet post-processing device 300 Stablize. In this embodiment, the sheet is base paper 400 .

[0018] It can be understood that, in the present invention, the sheet can also be non-woven fabric, cloth, film and other raw materials that need to maintain stable tension during the transmission process.

[0019] The sheet material transmission tension automatic adjustment device 100 includes a swing roller mechanism 10, which is arranged between the sheet material unwinding device 200 and the sheet material post-processing device 300 to increase or decrease the base paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com