PVC (polyvinyl chloride) carpet for high-sound-insulation vehicle and preparation method thereof

A vehicle and high-isolation technology, which is applied to carpets, vehicle parts, chemical instruments and methods, etc., to achieve the effect of improving acoustic quality, good sound insulation performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

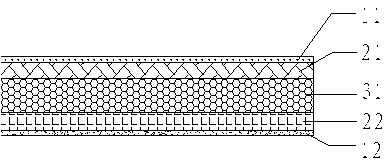

[0023] Such as figure 1 As shown, the high-sound insulation vehicle carpet made of PVC is made of five layers of materials and has a five-layer structure. From the surface layer to the bottom layer, there are an upper anti-skid layer 11, an upper sound insulation layer 21, and a foam layer 31. , the lower sound insulation layer 22 and the lower anti-slip layer 12; the materials of each layer are PVC materials, and the thickness, density and hardness of each layer of materials in each embodiment are specifically shown in Table 1 below. The upper anti-slip layer 11, the upper sound insulation layer 21, the foam layer 31, the lower sound insulation layer 22 and the lower anti-slip layer 12 are bonded by hot pressing to form a multi-layer constrained sheet, which is formed into a PVC material by heating and blistering. Carpets for high sound ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com