Composition structure of sound absorption and insulation composite material

A composite material, sound absorption and sound insulation technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

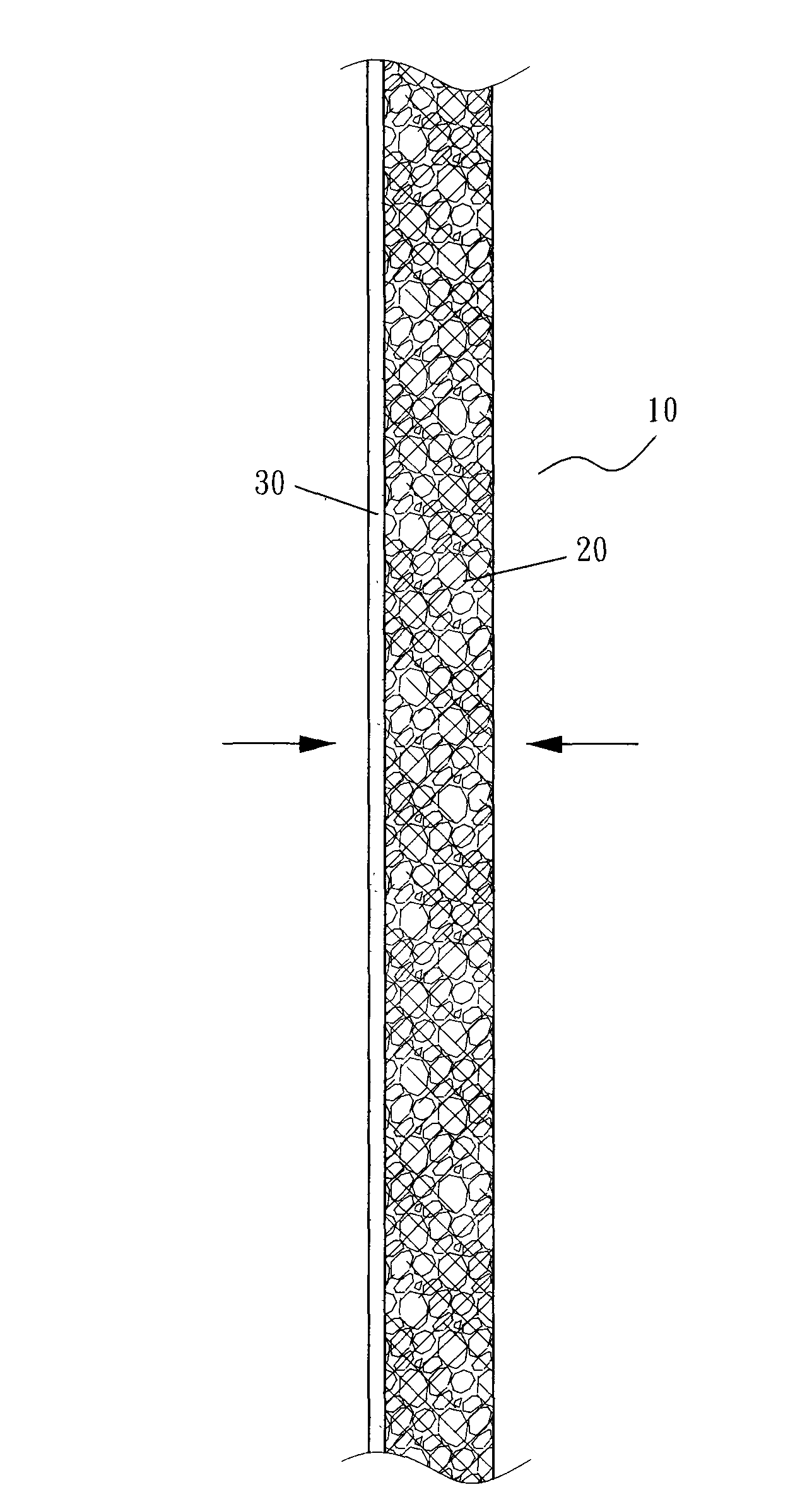

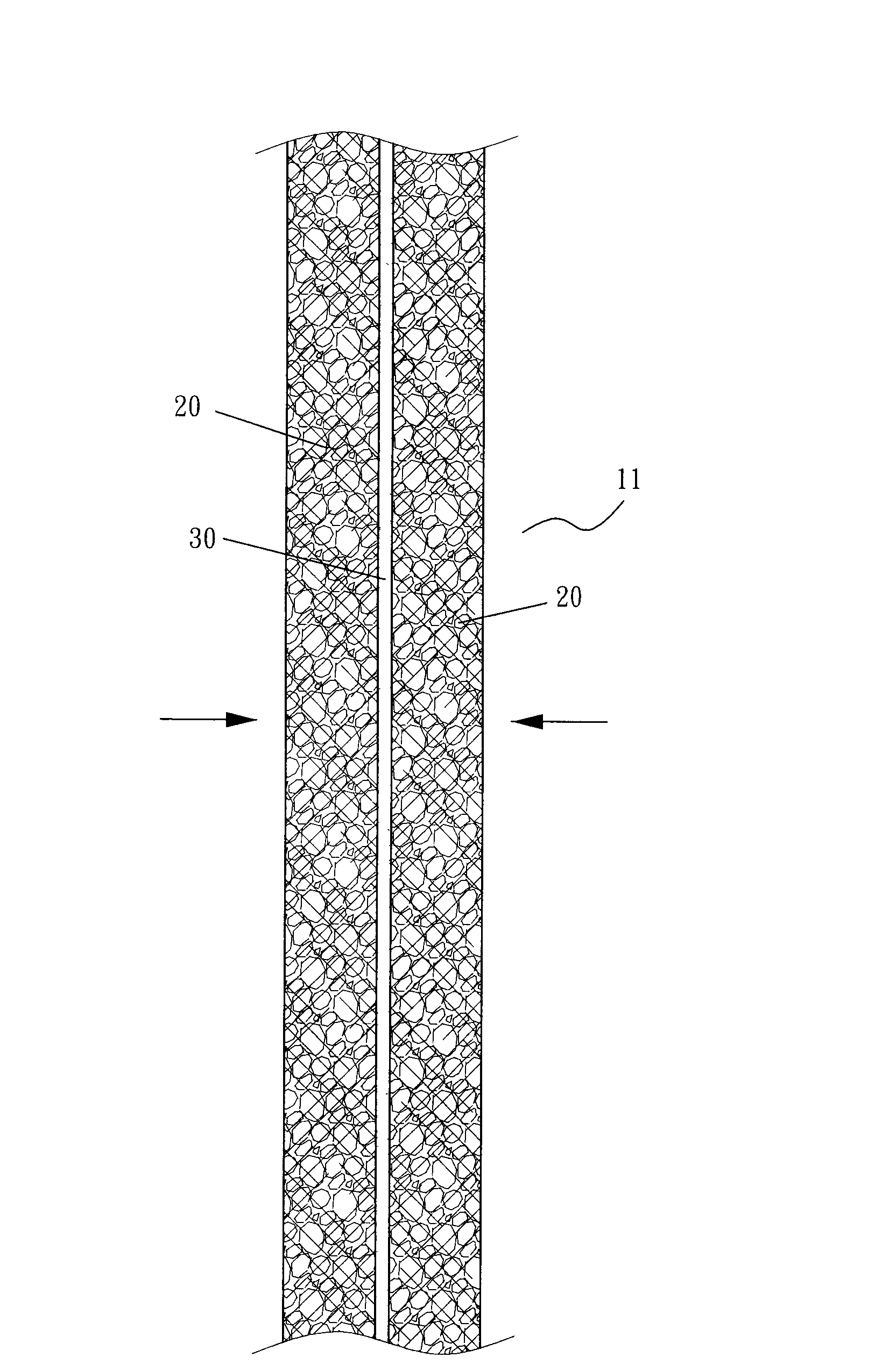

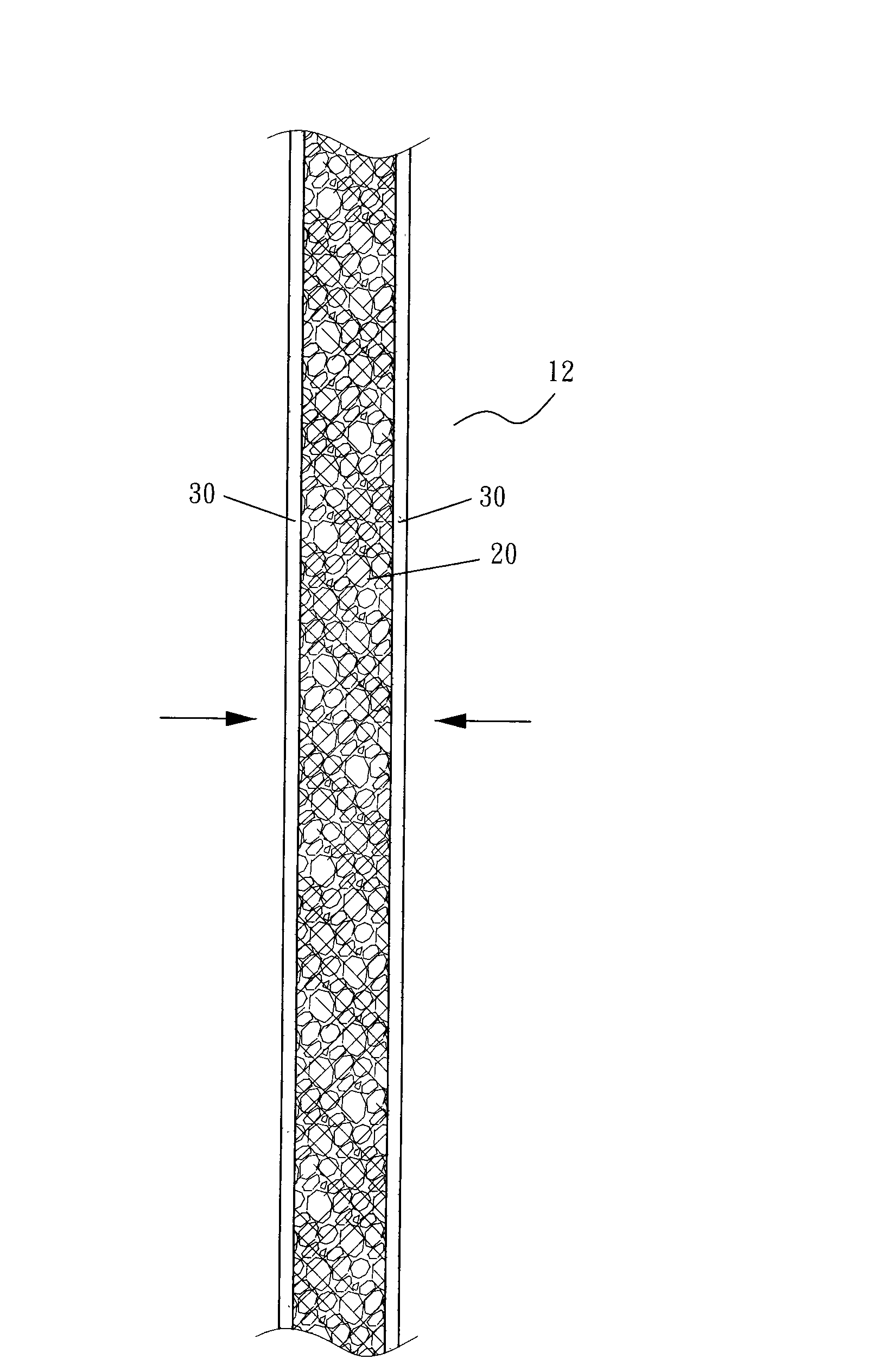

[0029] see figure 1 As shown, the first embodiment of the present invention is a sound-absorbing and sound-insulating composite material 10, which is composed of a layer of fiber non-woven fabric layer 20 and a layer of closed foam layer 30. Wherein, the fiber non-woven fabric layer 20 can be The fiber laminated layer made of any fiber material by non-woven fabric manufacturing method can be made of environmentally friendly recycled fiber material by non-woven fabric manufacturing method, so as to achieve the effect of environmental protection, energy saving and carbon reduction; the forming thickness of the fiber non-woven fabric layer 20 is 0.5mm (inclusive) above, the weight is 50g / m 2 up to 3000g / m 2Between them, the main function is to support a fiber stacked layer formed by interlacing and interlacing of many fibers, and there are many interlaced three-dimensional spaces inside; the closed foam layer 30 is a closed foam with many independent closed air holes. Body, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com