Integral type aluminum alloy sound barrier structure unit

A structural unit and integral technology, which is applied in the field of integral aluminum alloy sound barrier structural units, can solve problems such as inconvenience in engineering construction, achieve low maintenance costs, improve assembly efficiency, and facilitate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

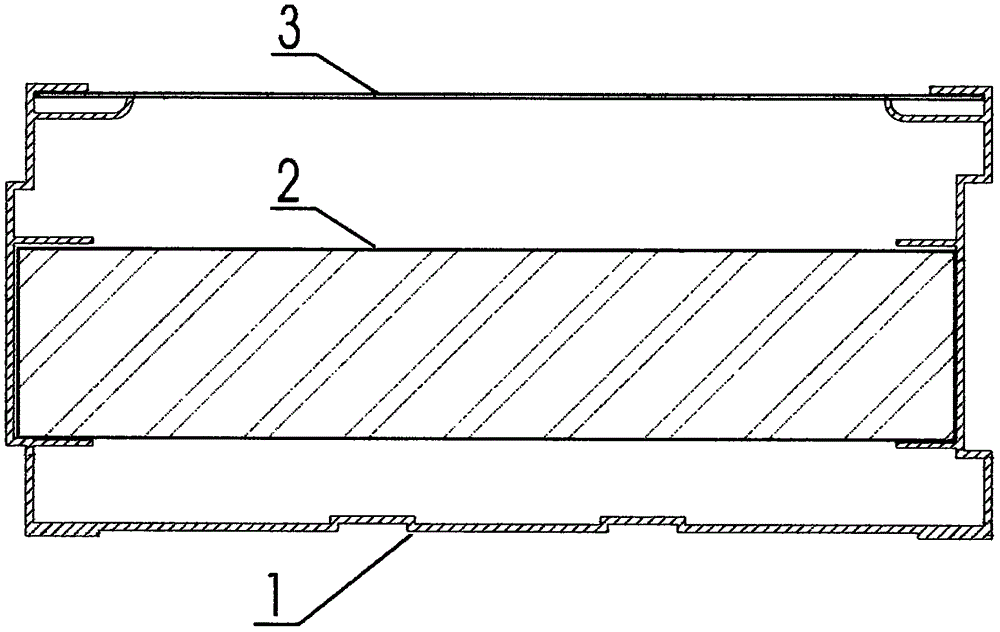

[0013] An integral aluminum alloy sound barrier structural unit, comprising an integral aluminum alloy bottom plate 1, sound-absorbing material 2, and mesh plate 3;

[0014] The integral aluminum alloy bottom plate 1 adopts an integral U-shaped structure, cooperates with local T-shaped and Y-shaped structures, and is made into an integral structural unit through an extrusion process. The thickness of the main body of the structural unit is 1.5mm;

[0015] The thickness of the sound-absorbing material 2 is 50 mm, and it is installed and fixed on the U-shaped structure of the integral aluminum alloy bottom plate 1;

[0016] The sieve plate 3 is installed on the Y-shaped structure of the integral aluminum alloy bottom plate 1 by plugging;

[0017] The thickness of the sieve plate 3 is 1.5mm, and the through-hole rate of the sieve plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com