Preparation method of PIF foamed polymer sound insulation material

A foamed polymer and sound insulation material technology, applied in the field of sound insulation materials, can solve the problems of heavy weight and low sound insulation, and achieve the effects of light weight, improved sound insulation performance, and dense crystal arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Dry PP in a constant temperature oven at 80°C for 6 hours, and dry PA6 in a constant temperature oven at 120°C for 12 hours. Take 100g of dried PP and 100g of dried PA6 (1:1 ratio) and mix them. Add 10g PP-g-MA compatibilizer (5wt.%, Sigma-Aldrich, specification: SA9100mark) and 1g antioxidant (5wt.‰, 1:1 mixture of antioxidant 1010 and coating antioxidant 168); Then, the material was blended with a Haake torque rheometer at a speed of 60r / min and a temperature of 230°C until the torque no longer changed with time, and it was recorded as PP / PA6.

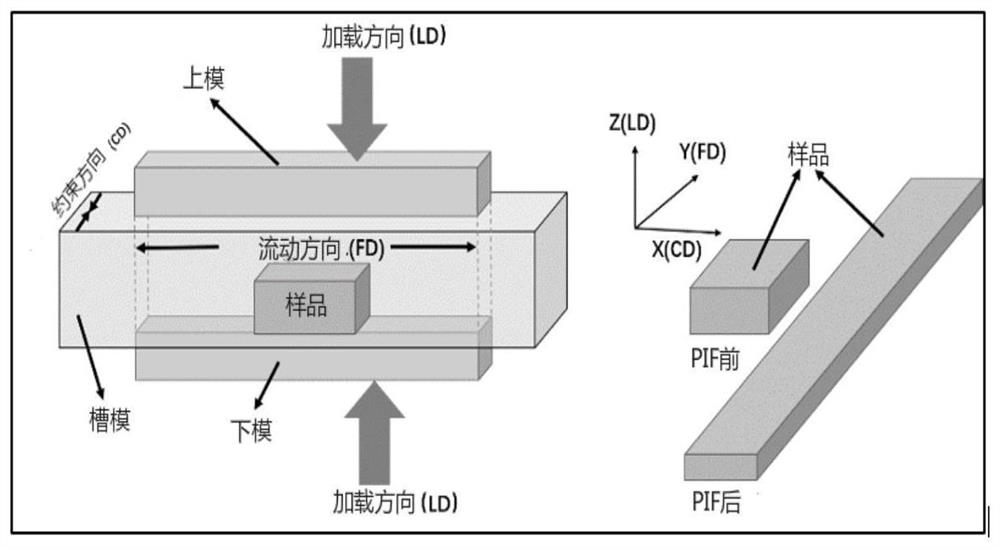

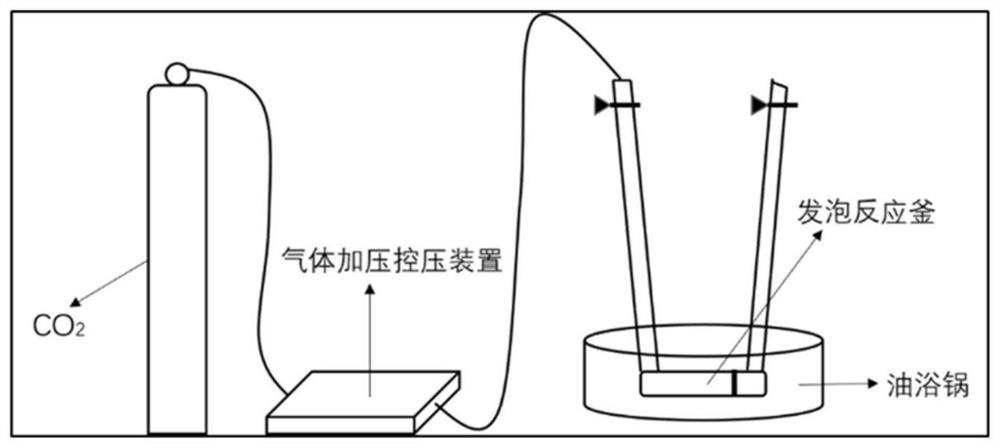

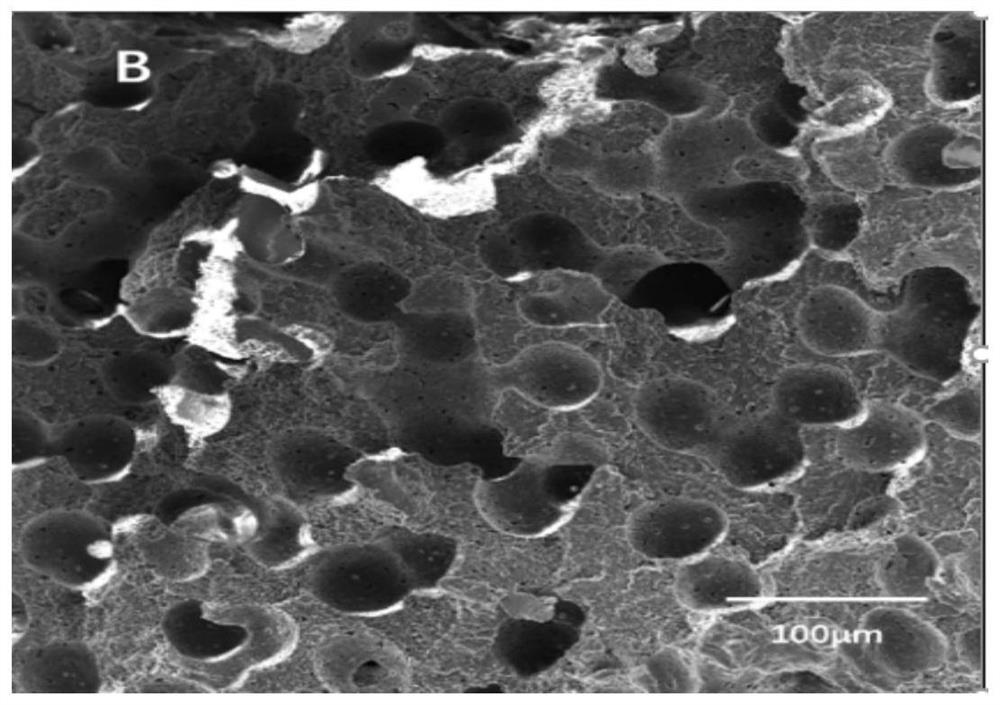

[0038] 2) Place PP / PA6 on a flat heating table and heat to 230°C. After the material is completely softened, put it into a mold to make a rectangular block sample of 50*30*6mm; then put it into a mold cavity of 150*30*12mm In the automatic tablet press, it is subjected to pressure-induced flow treatment at a temperature of 150°C and a treatment pressure of 8.5MPa, such as figure 1 As shown, a sample of 150*30*2mm is prepar...

Embodiment 2

[0042] 1) Dry PP in a constant temperature oven at 80°C for 6 hours, and dry POE in a constant temperature oven at 60°C for 8 hours. Take 100g of dried PP and 100g of dried POE (1:1 ratio) and mix them. Add 10g PP-g-MA compatibilizer (5wt.%) and 1g antioxidant (5wt.‰, 1:1 mixture of antioxidant 1010 and coating antioxidant 168); The instrument blends the materials at a speed of 60r / min and a temperature of 190°C until the torque no longer changes with time and then takes it out, which is recorded as PP / POE.

[0043] 2) Place PP / POE on a flat heating table and heat to 190°C. After the material is completely softened, put it into a mold to make a rectangular block sample of 50*30*6mm; then put it into a mold cavity of 150*30*12mm In the process, it was subjected to pressure-induced flow treatment at a temperature of 140°C and a treatment pressure of 8.5 MPa in a fully automatic tablet press to prepare a sample piece of 150*30*2mm, which was recorded as PIF PP / POE. The benchmark...

Embodiment 3

[0047] 1) Dry PP in a constant temperature oven at 80°C for 6 hours, and dry TPU in a constant temperature oven at 60°C for 8 hours. Take 100g of dried PP and 100g of dried TPU (1:1 ratio) and mix them. Add 10g PP-g-MA compatibilizer (5wt.%) and 1g antioxidant (5wt.‰, 1:1 mixture of antioxidant 1010 and coating antioxidant 168); The machine blends the materials at the parameters of rotating speed of 60r / min and temperature of 170°C until the torque no longer changes with time, then take it out, and record it as PP / TPU.

[0048] 2) Place PP / TPU on a flat heating table and heat to 170°C. After the material is completely softened, put it into a mold to make a rectangular block sample of 50*30*6mm; then put it into a mold cavity of 150*30*12mm In the process, it was subjected to pressure-induced flow treatment at a temperature of 130°C and a treatment pressure of 8.5 MPa in a fully automatic tablet press to prepare a sample piece of 150*30*2mm, which was recorded as PIF PP / TPU. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com