Groove type perforated plate staggered soundproof structure with air interlayers

A technology of staggered arrangement and air interlayer, applied in the direction of sound insulation, building components, noise absorption devices, etc., can solve the problems of energy consumption, complex overall structure, etc., achieve the effect of increasing scattering, improving sound insulation performance, and wide application area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

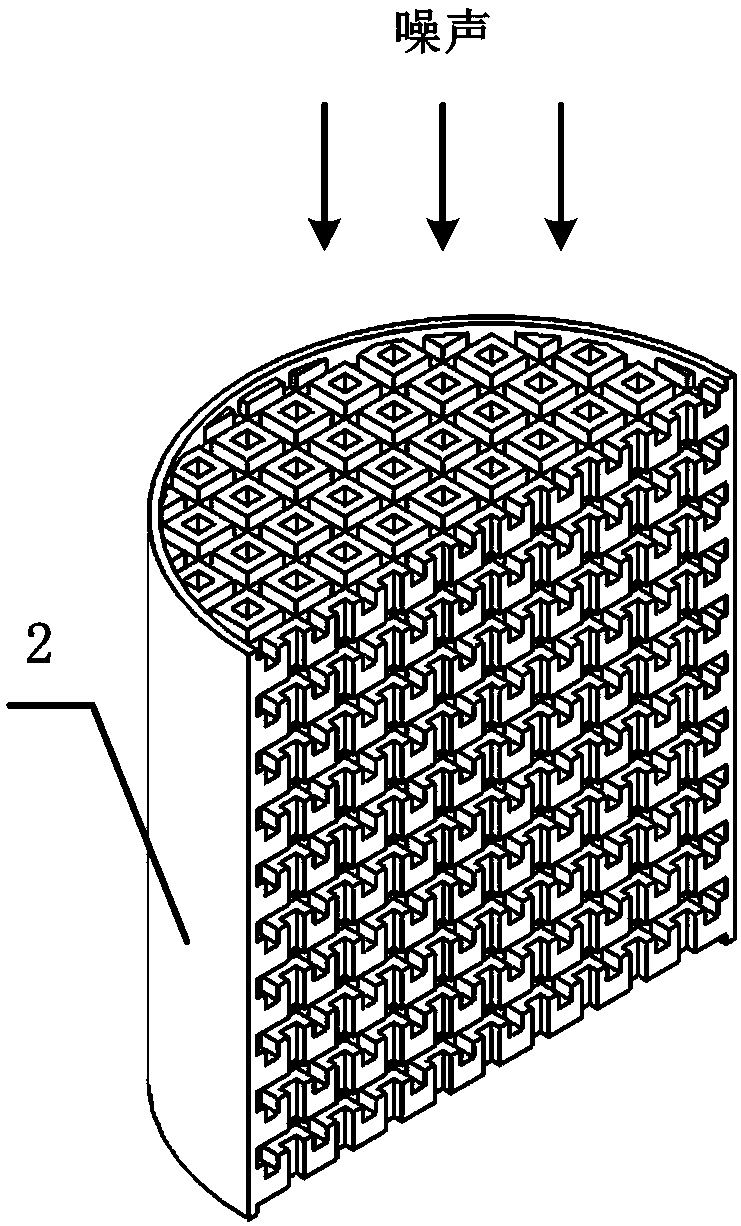

[0023] Such as figure 1 As shown in a, the overall shape of the sound insulation structure with staggered slot-type perforated plates in this embodiment, that is, the shell 1 is cylindrical, the diameter of the shell 1 is 29.8 mm, and the thickness is 30 mm. Its overall shape and thickness can be made according to actual engineering requirements. This embodiment includes a housing 1 and several layers of perforated plates 11 arranged in the housing 1 , and two adjacent perforated plates 11 are arranged alternately and provided with an air interlayer 13 . A plurality of grooves 12 are arranged on one side of the perforated plate according to two perforating directions perpendicular to each other. Among them, the thickness of the perforated plate is 2mm; the perforated section is square, and the square side length is 1mm; the perforation spacing of the perforated plate is 3mm; the groove width is 0.8mm, the depth is 0.8mm; the thickness of the air interlayer is 1mm. The outerm...

Embodiment 2

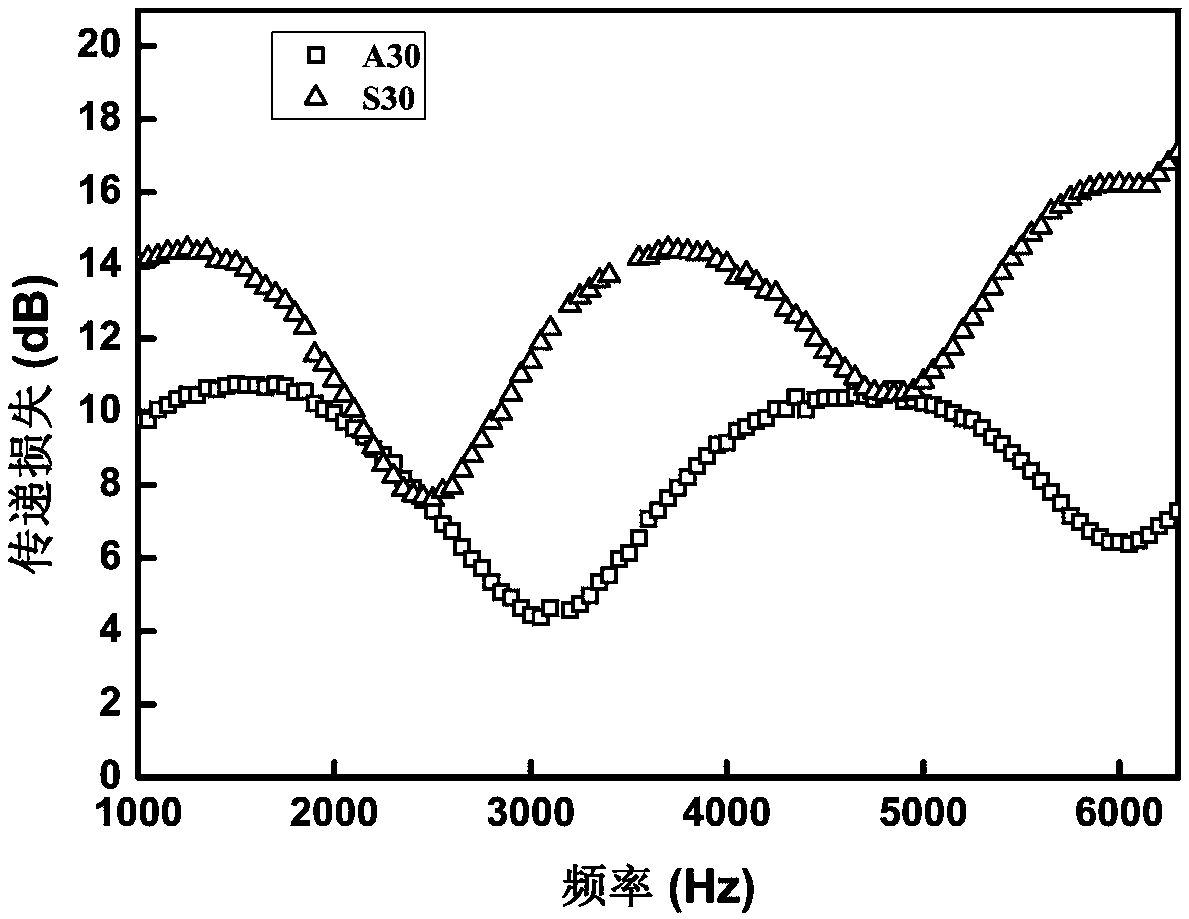

[0028] In this embodiment, the overall shape of the sound insulation structure with staggered arrangement of slot-type perforated plates is cylindrical, the diameter of the sample is 29.8 mm, and the thickness is 60 mm. In this embodiment, a sound insulation structure arranged in rows of grooved perforated plates is selected as a comparison, and its overall shape is cylindrical and its thickness is 60 mm.

[0029] The SW477 impedance tube manufactured by Beijing Shengwang Shengdian Technology Co., Ltd. was used to test the transmission loss of the staggered arrangement of slot-type perforated plates and the sound insulation junctions of the parallel arrangement involved in Example 2. The test frequency range is 1000Hz-6300Hz. During the test, the side of the sample with the groove faces the noise source.

[0030] Figure 5 When the shape is the same (the sample diameter is 29.8mm and the thickness is 60mm), the transmission loss of the staggered arrangement of slot-type perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com