Automatic pressure pin, choke plug and pressure plate system for camshaft

An automatic pressing pin and camshaft technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of wasting manpower, safety hazards, time wasting, etc., to save processing time, reduce safety hazards, and reduce manpower input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

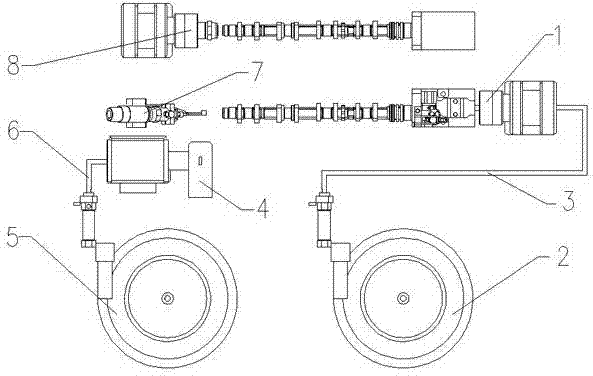

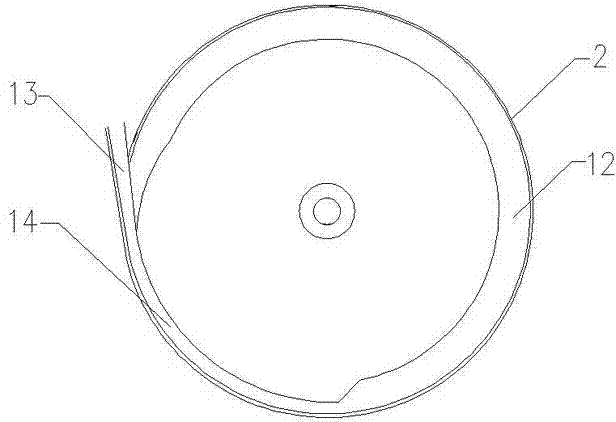

[0025] The invention provides a camshaft automatic pressure pin, pressure plug, and pressure plate system, including a system support frame, a pressure plate device for pressing a signal plate on the rear end of a camshaft is installed on the system support frame, for Gluing device for applying glue to the shaft tube at the rear end of the camshaft, a pin pressing device and a plugging device for pressing the pin and plug into the pin hole at the front end of the camshaft and the shaft tube at the rear end, and a plugging device for detecting plugging A leak detection device for whether the shaft tube of the head and the camshaft is sealed. The system support frame is also provided with a manipulator for transporting the camshaft between the devices and an industrial computer for controlling the automatic operation of the devices and the manipulator.

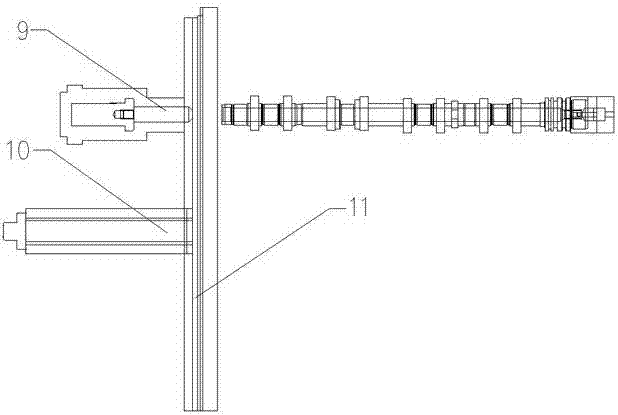

[0026] see figure 1 , 2 , 3 and 4, the pin pressing device can include a pin automatic feeding mechanism, a pin positioning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com