Soldering system of waste printed-circuit board

A waste printed circuit board and processing system technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as low efficiency, inability to meet large-scale processing of waste printed circuit boards, etc., to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to improve the speed and treatment effect of waste printed circuit boards and realize the large-scale processing of waste printed circuit boards, the present invention provides a soldering treatment system for waste printed circuit boards. By using a transfer device and a control module, the The automatic processing of waste printed circuit boards is improved, the working efficiency of waste printed circuit boards is improved, and the waste printed circuit boards are processed in large quantities. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

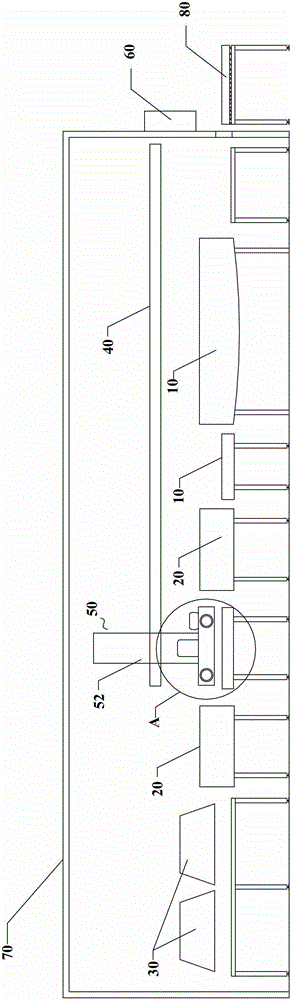

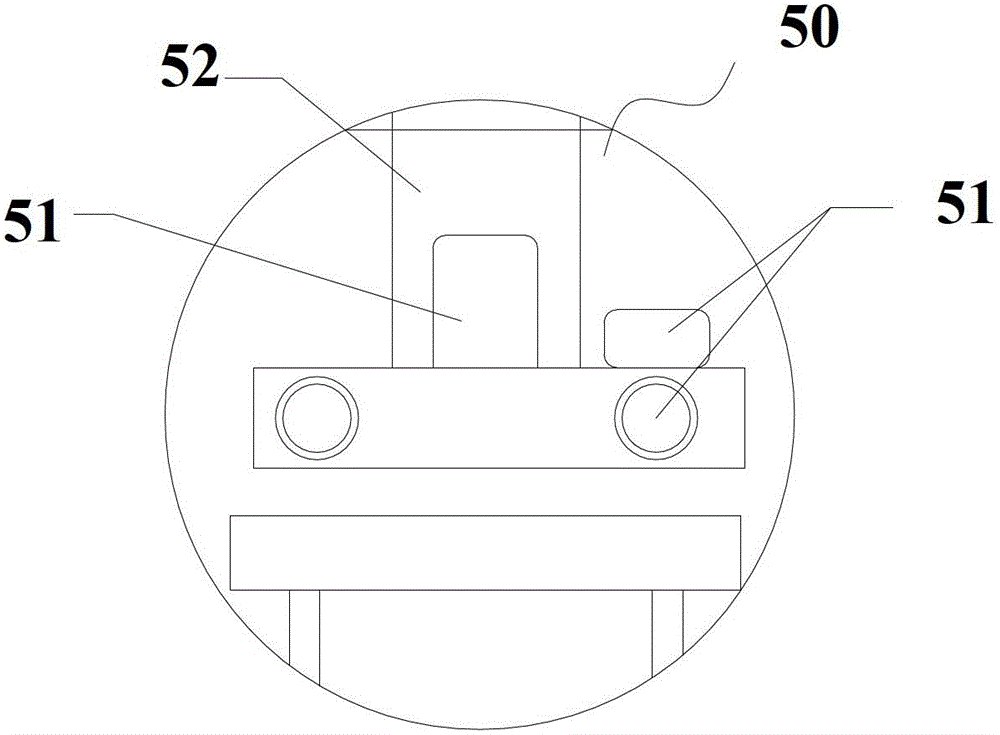

[0029] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a waste printed circuit board solder processing system provided by an embodiment of the present invention. by figure 1 The placement orientation of the solder handling system for scrap printed circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com