Simulation method, simulation program, and semiconductor manufacturing apparatus

A simulation method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, CAD numerical modeling, complex mathematical operations, etc., can solve problems such as sensor deterioration and high emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

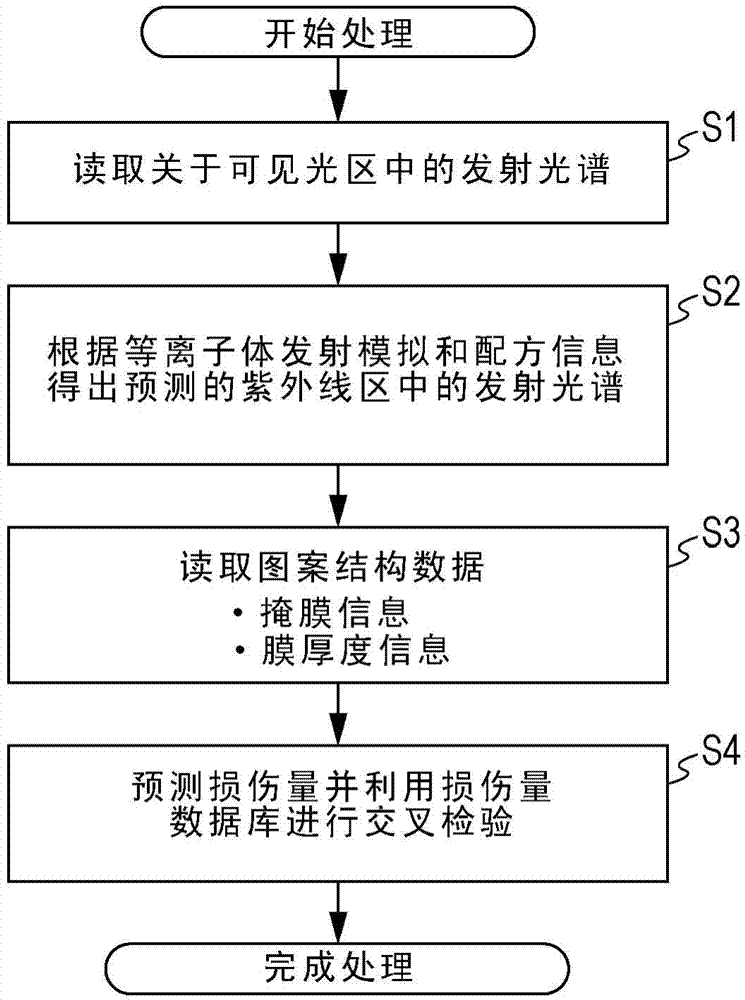

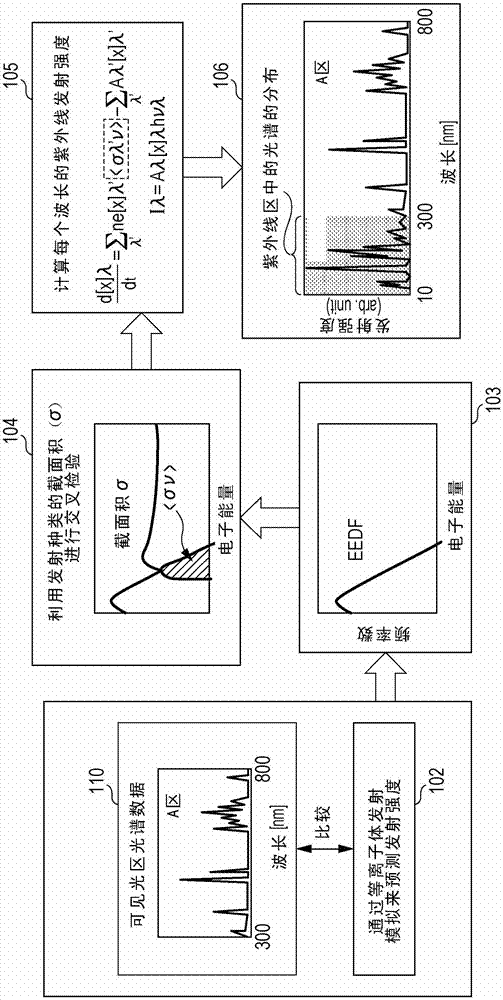

[0081] 2. First embodiment (simulation method)

[0082] 3. The second embodiment (simulator)

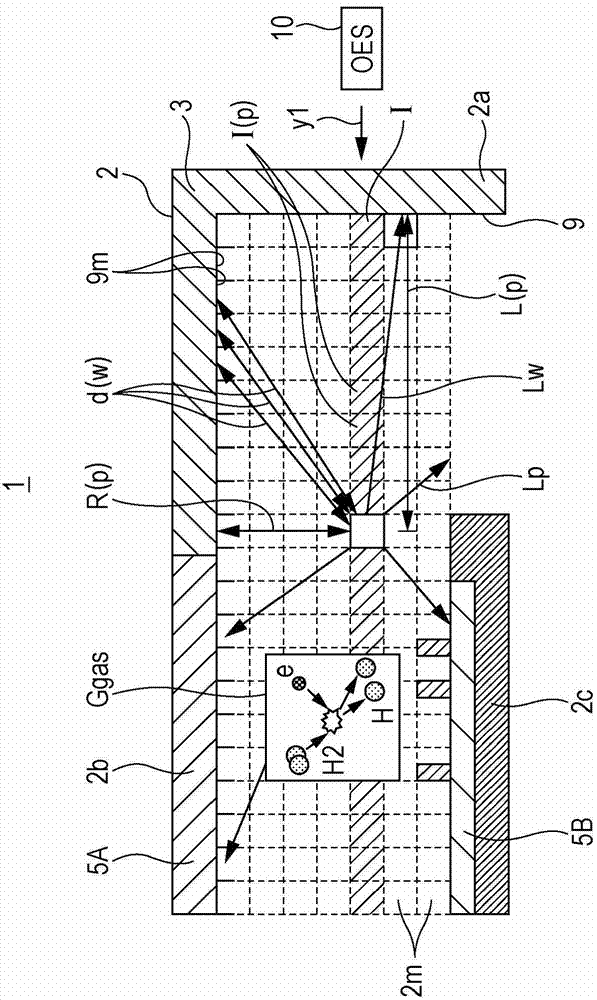

[0083] 4. The third embodiment (dry etching device)

[0084] 5. Fourth Embodiment (Dry Etching Apparatus)

[0085] 6. Fifth Embodiment (Dry Etching Apparatus and Etching Treatment Method)

[0086] 1. Outline of this disclosure

[0087] First, an outline of the present disclosure will be described before describing specific embodiments.

[0088] According to an embodiment of the present disclosure, the ultraviolet emission spectrum is predicted by performing simulations based on data of the visible emission spectrum without directly monitoring the ultraviolet emission.

[0089] Furthermore, the amount of damage to the film is predicted by performing simulation using the result of prediction of the ultraviolet emission spectrum by the simulation as input information.

[0090] Furthermore, for the purpose of reducing damage due to ultraviolet rays in real time, a semiconductor manu...

no. 6 example

[0368] 2. Sixth embodiment (simulation method)

[0369] 3. The seventh embodiment (simulator)

[0370] 4. Eighth embodiment (dry etching device)

[0371] 5. Ninth Embodiment (Dry Etching Apparatus)

[0372] 6. Tenth Embodiment (Dry Etching Apparatus and Etching Treatment Method)

[0373] 1. Outline of this disclosure

[0374] First, an outline of the present disclosure will be described before describing specific embodiments.

[0375] According to an embodiment of the present disclosure, the ultraviolet emission spectrum is predicted by performing simulations based on data of the visible emission spectrum without directly monitoring the ultraviolet emission.

[0376] Furthermore, the amount of damage to the film was predicted using the result of prediction of the ultraviolet emission spectrum by simulation as input information.

[0377] Furthermore, in order to reduce damage due to ultraviolet rays in real time, a semiconductor manufacturing device on which software based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com