The technical method of joint application of multiple composite pavement materials to pave the deck of highway steel bridges

A combined application and pavement material technology, which is applied in the direction of on-site paved condensate pavement, roads, roads, etc., to achieve good promotion and use value, bad weather adaptability, and anti-oxidation and corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

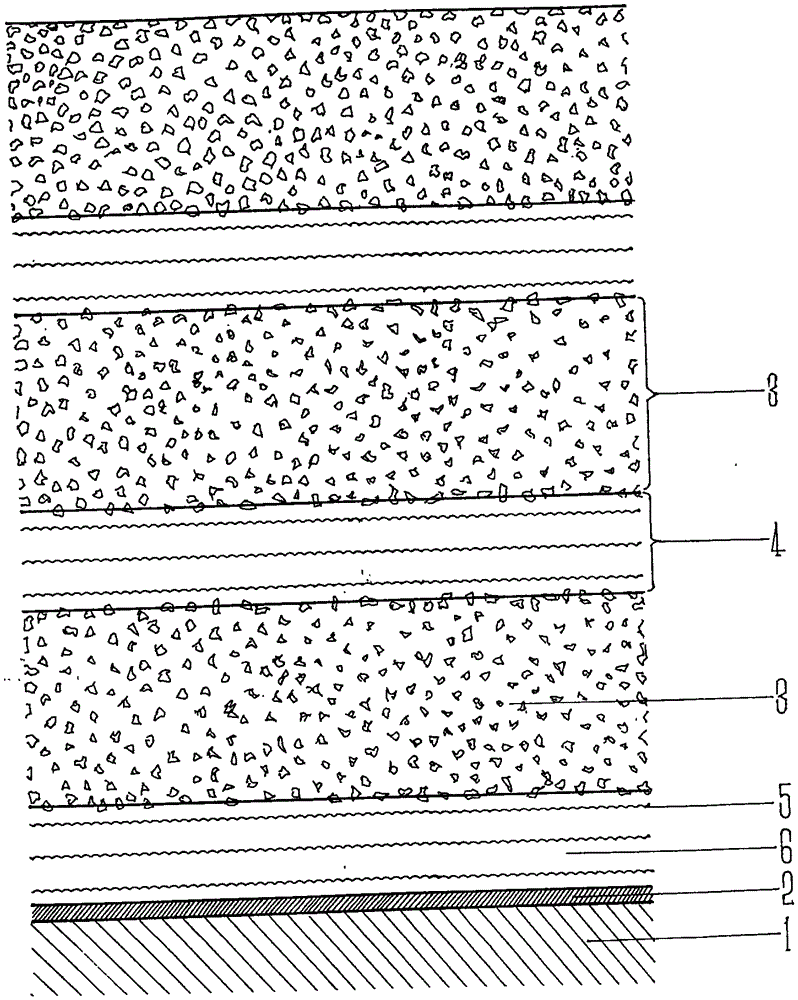

[0015] as attached figure 1 As shown, multiple composite paving materials of the present invention are jointly applied to the technical method of paving the deck of a highway steel bridge, and its structure includes an adhesive layer 2, a bulk material 3 and a roll material 4. The adhesive layer 2 is a spray paint with waterproof, anti-rust, stable physical and chemical properties, and strong adhesion with the steel bridge deck 1. The coiled material 4 is a sheet-like pavement material composed of inorganic, high-strength, and low-elastic filament braids as the supporting grid 5 and polyurethane asphalt concrete as the filler 6, which can be rolled and spread. Bulk material 3 is modified asphalt concrete with more coarse aggregate, more mineral powder, more asphalt and less fine aggregate.

[0016] During construction, the steel bridge deck 1 is derusted and cleaned, the spray coating is evenly and tightly sprayed, and cured to form an adhesive layer 2, the paving coil 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com