Lithium ion battery

A lithium-ion battery, electrolyte technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high temperature performance deterioration, increased contact area, structural changes, etc., to achieve excellent cycle life and storage life, suppress DC Increase of internal resistance, effect of inhibiting oxidative decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

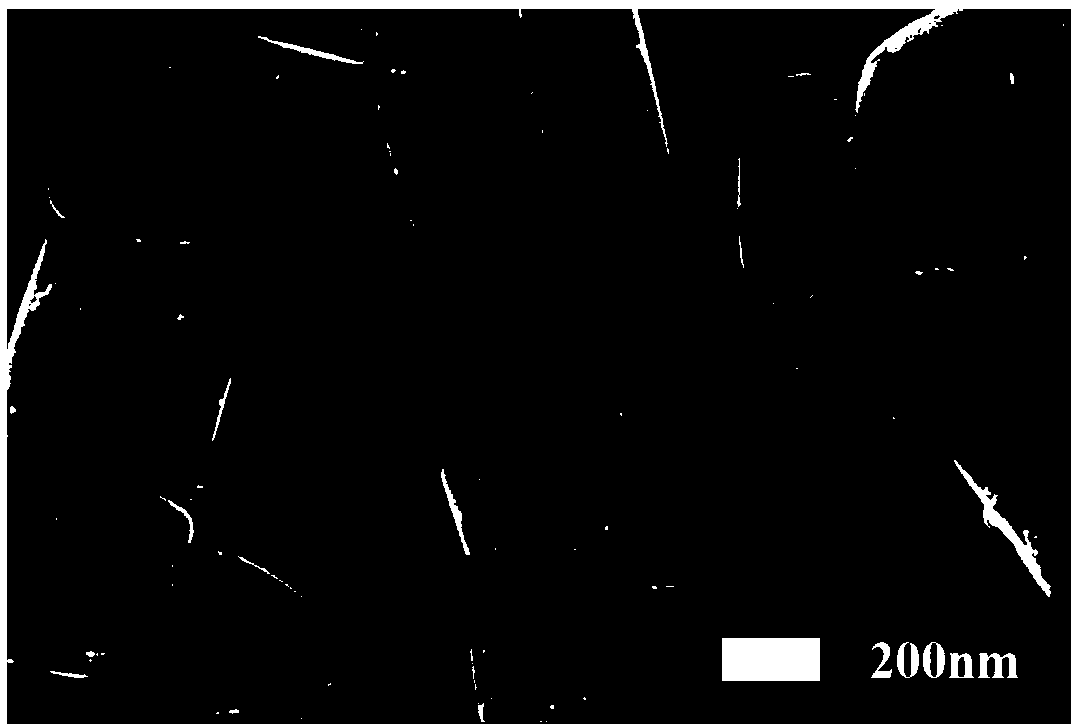

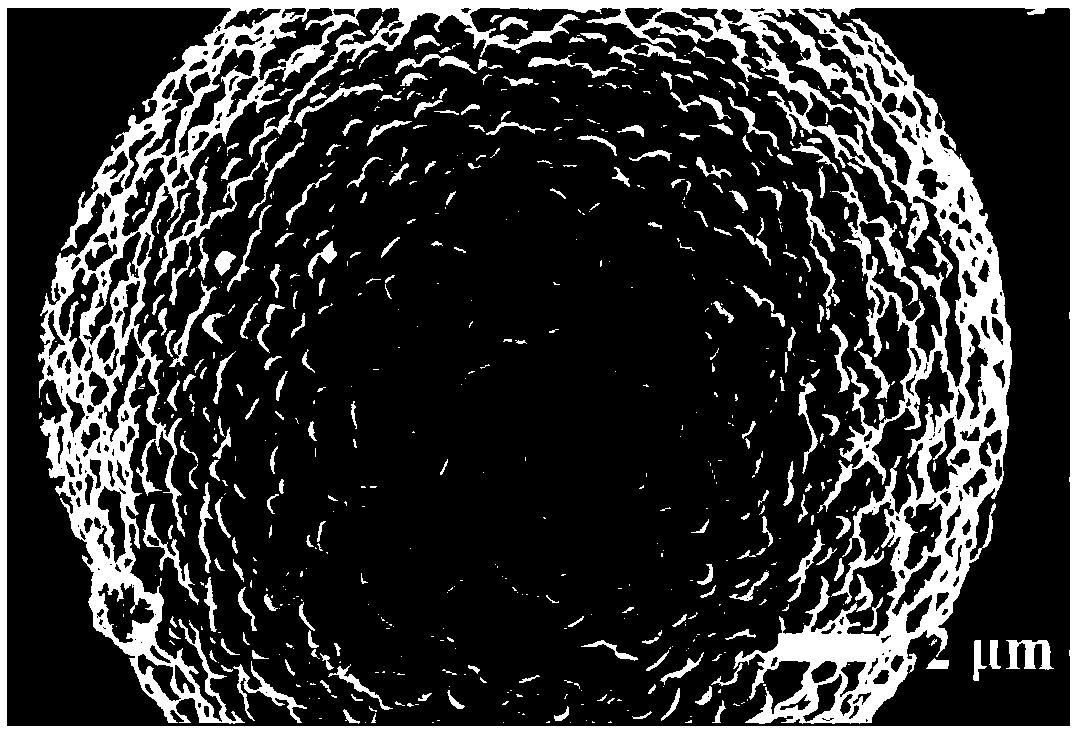

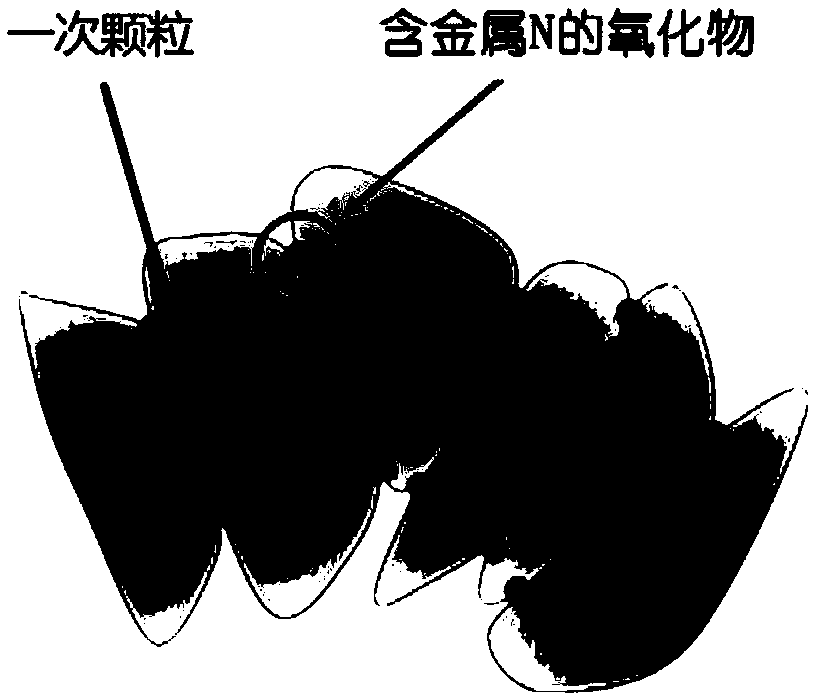

[0031] In the lithium ion battery of the present invention, the preparation method of the positive electrode active material may include the steps: S1, adding metal N oxide nanoparticles into deionized water, stirring and ultrasonic vibration, to obtain a uniformly dispersed metal N oxide aqueous solution; S2, The matrix Li of the positive electrode active material x Ni y co z m k Me p o r A m Add it to the metal N oxide aqueous solution, stir to dissolve the residual lithium on the surface of the substrate in the water, the metal N oxide nanoparticles are attached to the surface of the substrate, and then filter and dry to remove the solvent to obtain a powder; S3, the obtained in step S2 The powder is mixed with a simple substance or compound containing element N', and then heat-treated to obtain a positive electrode active material.

[0032] In the preparation method of the positive electrode active material, the substrate is washed with water while the first coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com