Phosphated metal rust-proof oil and preparation method thereof

A metal rust prevention and phosphating technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of metal rust, film weight, phosphoric acid surface rust, etc., and achieve the effect of preventing scratches, low viscosity, and improving grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 phosphating metal antirust oil

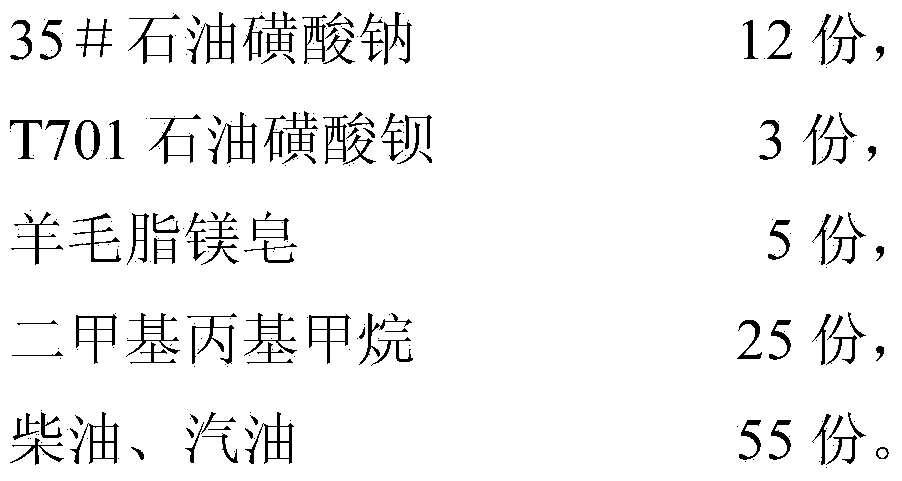

[0052] A kind of phosphating metal antirust oil, according to parts by weight, has the following components

[0053]

[0054] Formulation of table 1 phosphating metal antirust oil

[0055]

Recipe 1

Recipe 2

Recipe 3

Rust inhibitor 1

10

12

15

Rust inhibitor 2

2

3

1

8

5

2

stabilizer

20

25

30

Co-solvent

60

55

50

[0056] A preparation method of phosphating metal antirust oil, comprising the following steps:

[0057] (a) Add antirust agent 1 and antirust agent 2 into the reaction kettle, and stir at room temperature;

[0058] (b) Add soap agent and stir for 10-20 minutes;

[0059](c), adding a stabilizer and stirring for 10-20 minutes respectively; and

[0060] (d) After adding a co-solvent and stirring for 10-20 minutes, the phosphating metal antirust oil is obtained.

[0...

Embodiment 2

[0062] The detection of embodiment 2 phosphating metal antirust oil

[0063] The detection of phosphating metal antirust oil includes the following steps:

[0064] (1) Batch rules: products of the same shift, same specification, and same level are grouped together, and 2L are drawn from them:

[0065] (2) Sampling: Sampling shall be carried out according to GB / T4756, and 2L shall be taken as inspection samples and reserved samples.

[0066] (3) Factory inspection items: kinematic viscosity, flash point, kinematic viscosity test, corrosion test, damp heat test, salt spray test, sealed anti-rust test (steel sheet).

[0067] (4) Type inspection: type inspection is the entire content of the technical requirements of this standard, and type inspection should be carried out in any of the following situations;

[0068] a) When new products are put into production and changes in raw materials and processes may affect product performance;

[0069] b) When production is resumed after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com