Middle combustion beam for shaft furnace

A technology of burning beam and shaft furnace, applied in the field of kiln equipment, can solve the problems of loss of oil resources, structural rupture, large energy consumption, etc., and achieve the effects of reducing investment and maintenance costs, prolonging service life, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

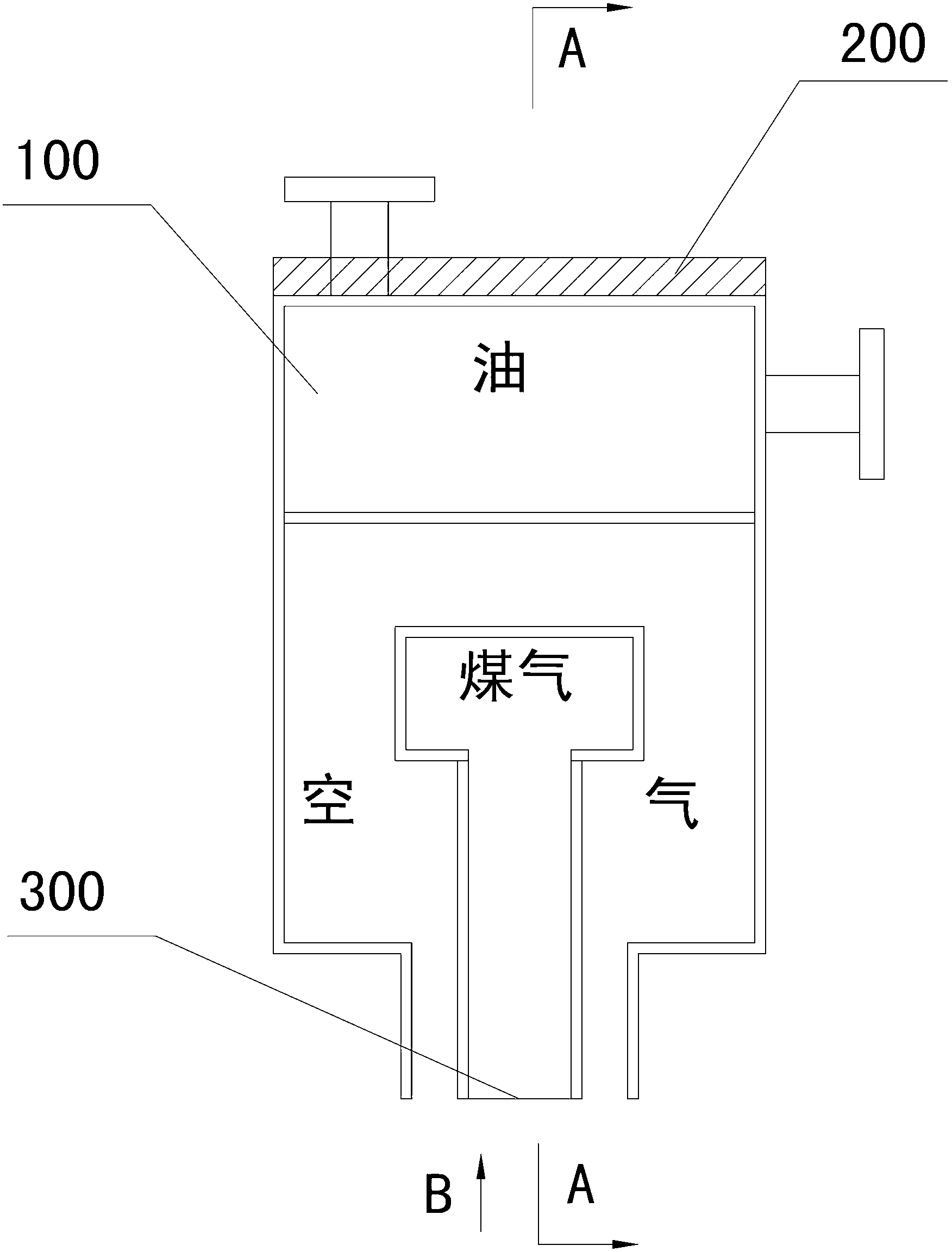

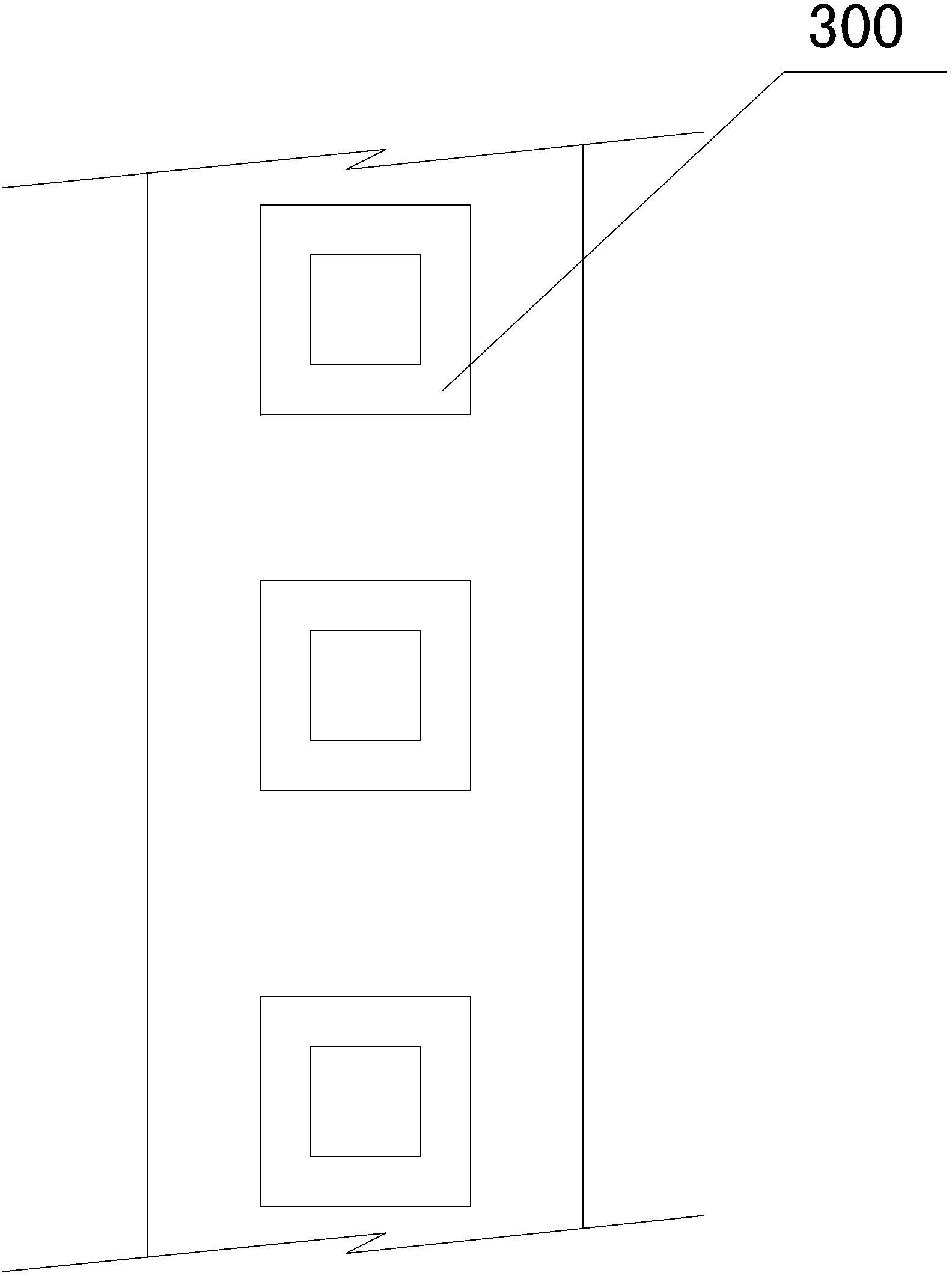

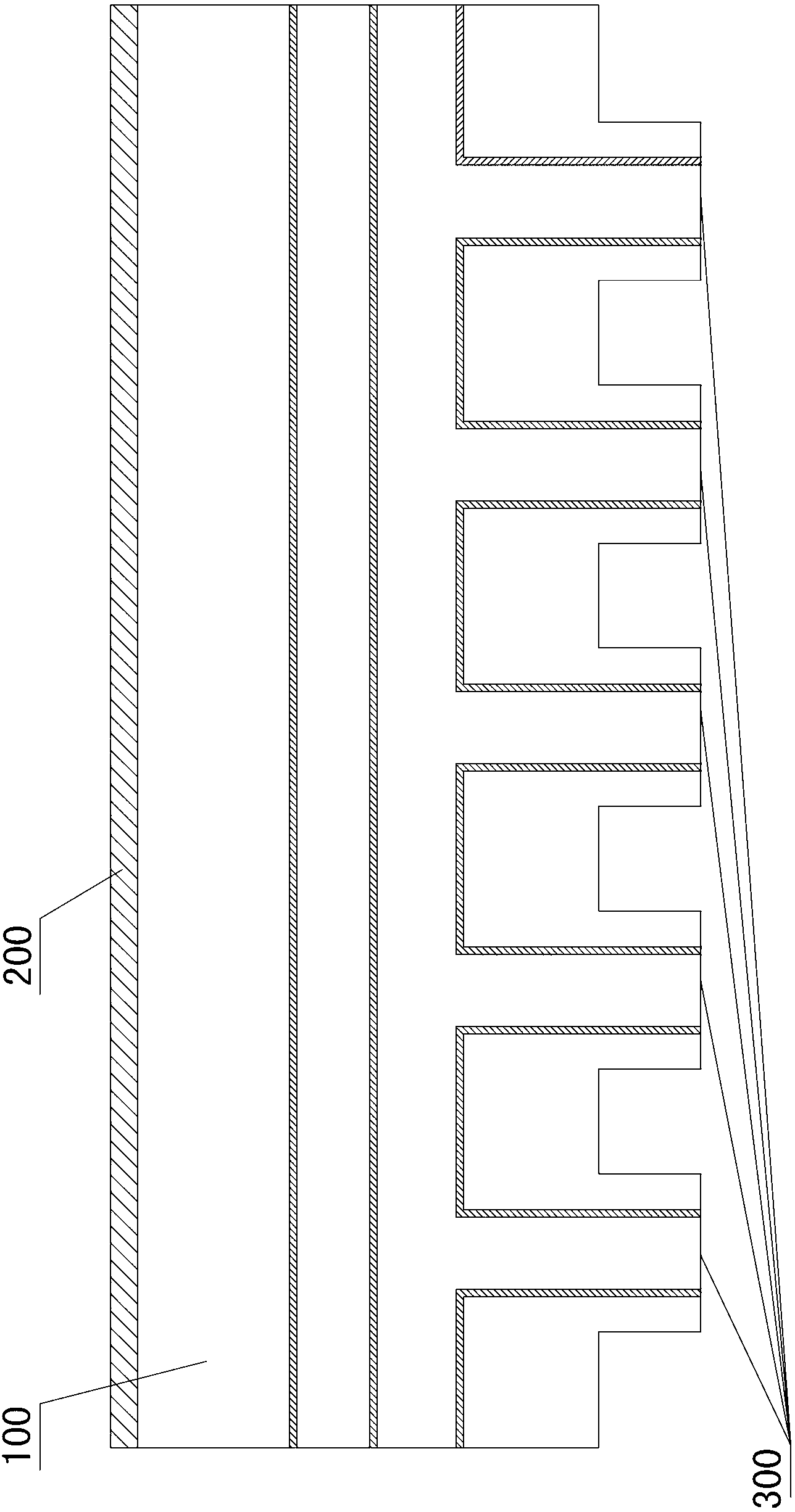

[0034] Such as Figure 4 , Figure 5 and Figure 6 As shown, the present invention is used for the central combustion beam of the shaft furnace, including a cavity 5 and more than one central burner assembly 4 installed in the cavity 5, the bottom of the cavity 5 is provided with a flame ejection port 6, and the cavity 5 is formed by a plurality of water-cooled beams 3 lapped and surrounded. The water-cooled beams 3 are fed with circulating water during operation to reduce the temperature of the middle burner assembly 4 during operation, thereby protecting the middle burner assembly 4 . The water-cooled beam 3 can be made of seamless steel pipe, which has a firm structure, strong load-bearing capacity, is not easy to break, and will not leak. By changing the existing oil-cooled structure into a water-cooled structure, the investmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com