Method and device for assembling and forming wood box

A molding device and molding method technology, applied in the directions of packaging, transportation and packaging, and box making operations, can solve the problems of not meeting the bonding requirements of wooden boxes of different specifications, increasing the production time of wooden boxes, and low degree of automation. High production efficiency, reduced scrap rate, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

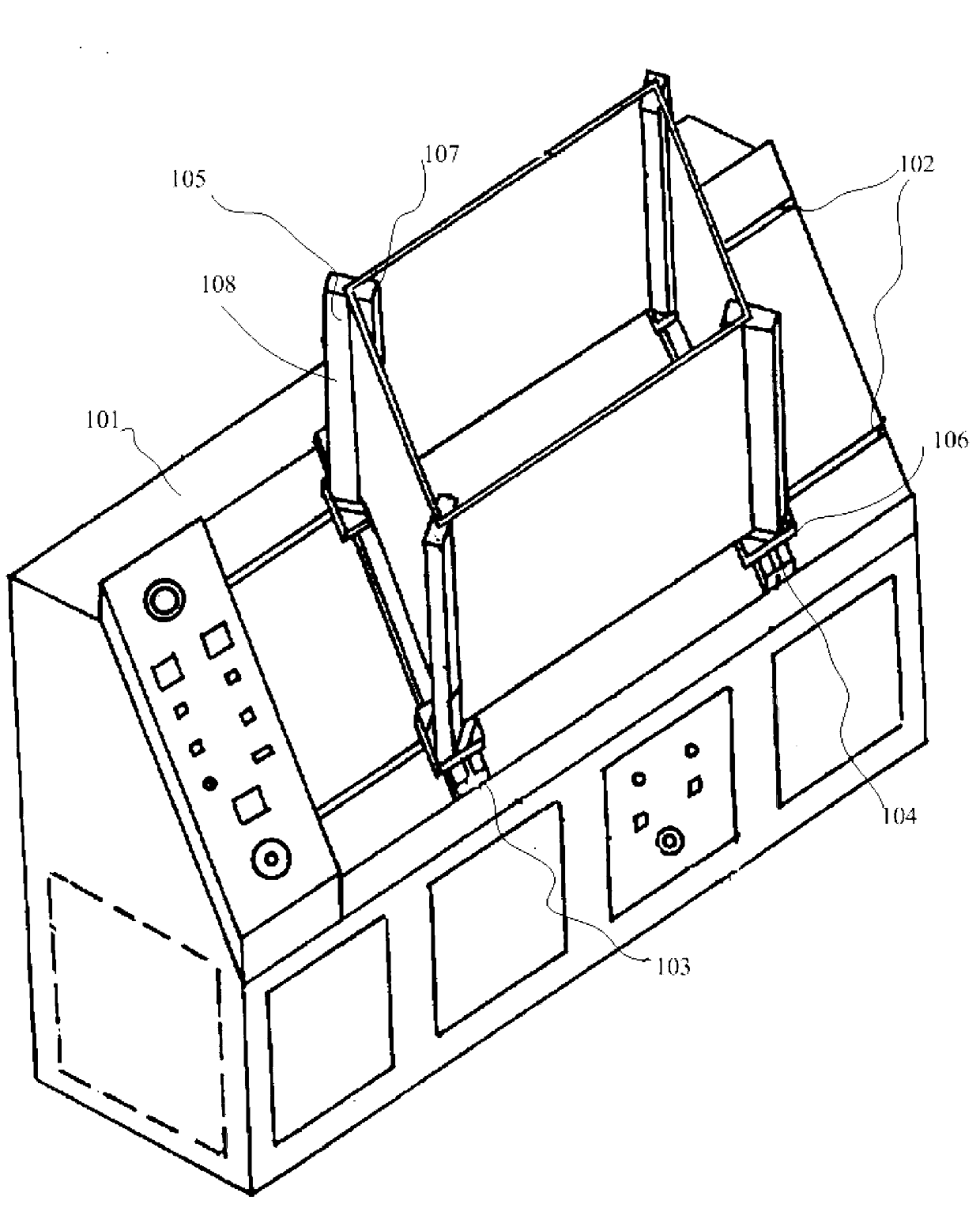

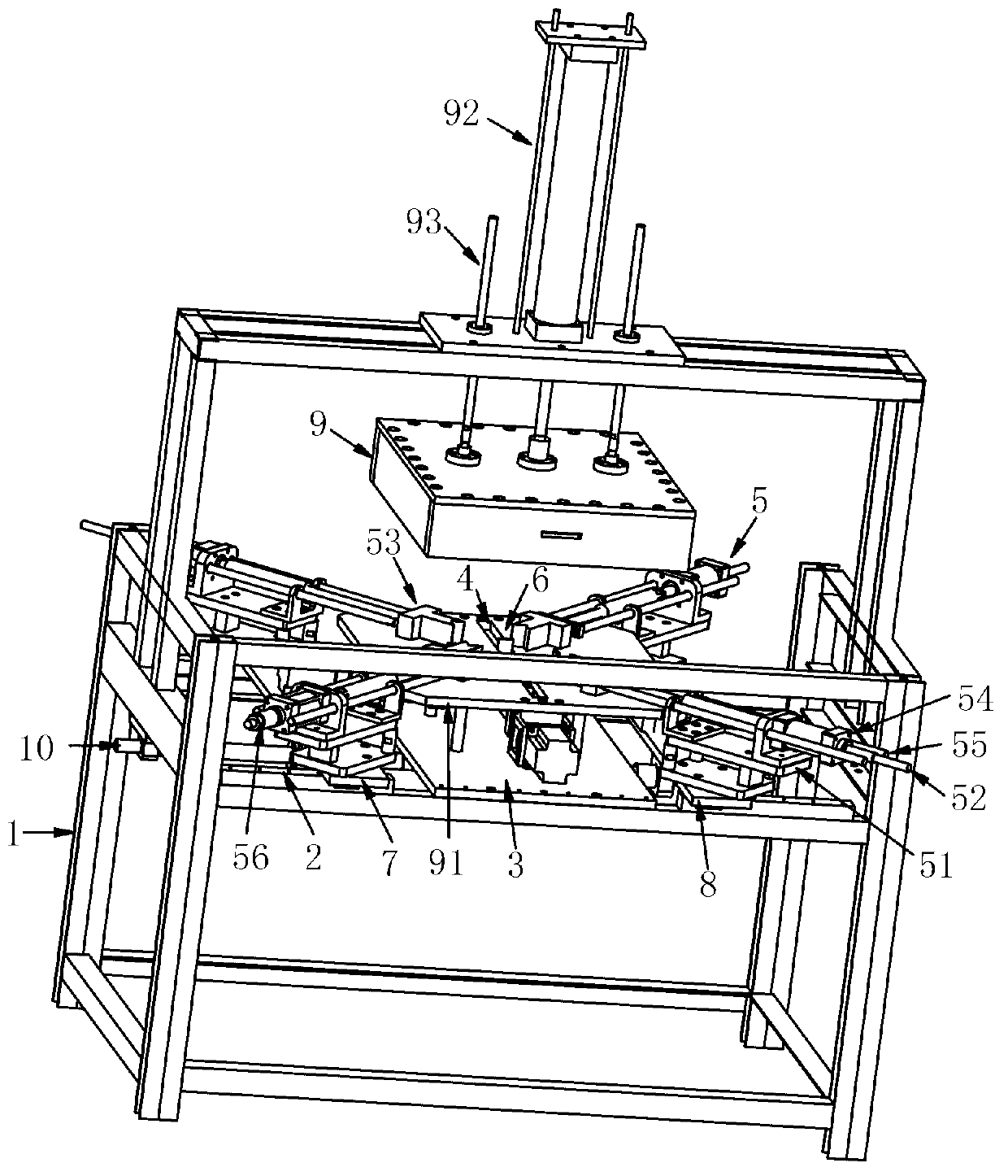

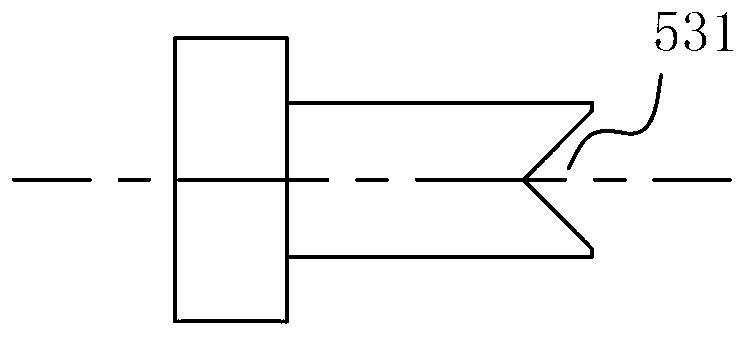

[0059] Such as figure 2 As shown, the wooden box assembly and molding device described in this embodiment is used to produce square or rectangular wooden boxes, including an elastic push limit clamping device 5 for automatic positioning from the outside of the wooden box, and a The inner limit device for automatic limit on the inside of the box 6, the high-frequency generator and control system for fast drying glue on the assembled wooden box, this control system is respectively connected with the elastic push limit clamping device 5, the inner limit The device 6 is connected with the high-frequency generating device, so that the elastic advance limit clamping device 5, the inner limit device 6 and the high-frequency generating device are all controlled by the control system to realize automatic control.

[0060] The elastic propulsion limit clamping device 5, the inner limit device 6 and the high-frequency generating device are placed on the frame 1, and the frame 1 is provi...

Embodiment 2

[0078] The wooden box assembly molding device described in this embodiment is used to produce triangular wooden boxes, including an elastic push limit clamping device for automatic limit from the outside of the wooden box, and an automatic limit clamp from the inside of the wooden box. The internal limit device, the high-frequency generating device and the control system for fast drying glue on the assembled wooden box, this control system is respectively connected with the elastic push limit clamping device, the internal limit device and the high-frequency generating device to The elastic push limit clamping device, the inner limit device and the high-frequency generating device are all controlled by the control system to realize automatic control.

[0079] The elastic push limit clamping device, the inner limit device and the high-frequency generating device are placed on the frame, and the frame is provided with a placement table for placing wooden boxes, and the placement t...

Embodiment 3

[0086] The wooden box forming device described in this embodiment is used to produce hexagonal wooden boxes, including an elastic push limit clamping device for automatic limiting from the outside of the wooden box, and an automatic limit clamping device for automatic limiting from the inside of the wooden box. The internal limit device, the high-frequency generator and control system for fast drying glue on the assembled wooden box, the control system is respectively connected with the elastic push limit clamping device, the internal limit device and the high-frequency generator, So that the elastic advance limit clamping device, the inner limit device and the high-frequency generating device are all controlled by the control system to realize automatic control.

[0087] The elastic push limit clamping device, the inner limit device and the high-frequency generating device are placed on the frame, and the frame is provided with a placement table for placing wooden boxes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com