Fusion epoxy powder coating surface processing device and adjusting method thereof

A technology of melting epoxy powder and surface treatment device, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc. The uneven surface texture of the layer affects the anti-corrosion effect of the prefabricated anti-corrosion layer of the steel pipeline, etc., to achieve the effects of stable lifting, uniform grinding effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

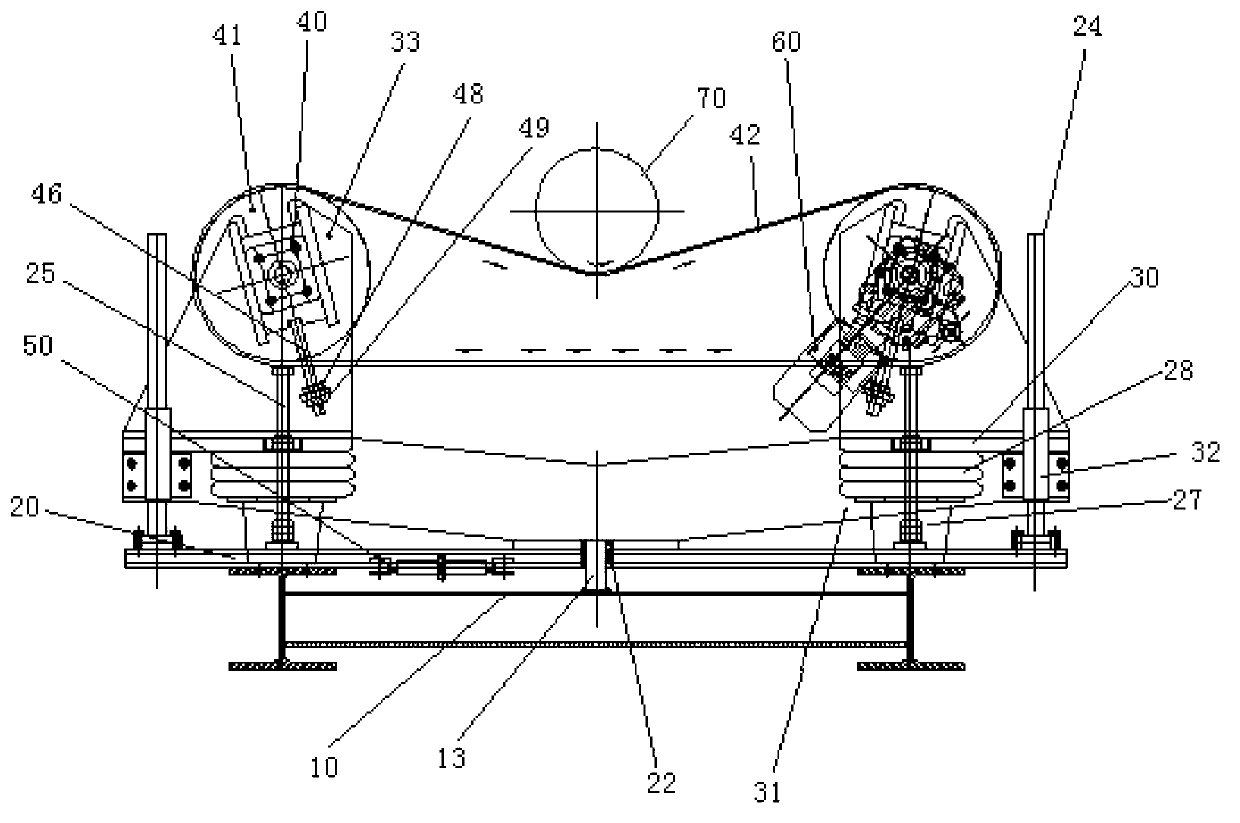

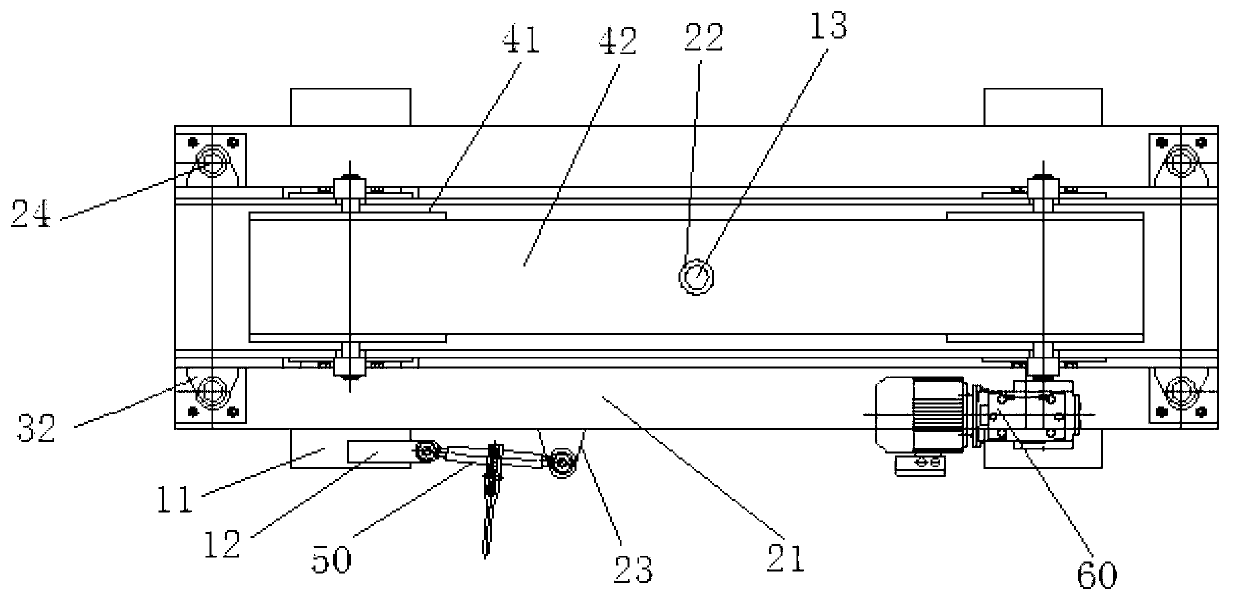

[0025] like figure 1 , figure 2 As shown, the present invention includes a supporting device 10 , a guide rod bracket 20 , a lifting bracket 30 , a roller adjusting device 40 , a screw adjusting assembly 50 and a driving device 60 .

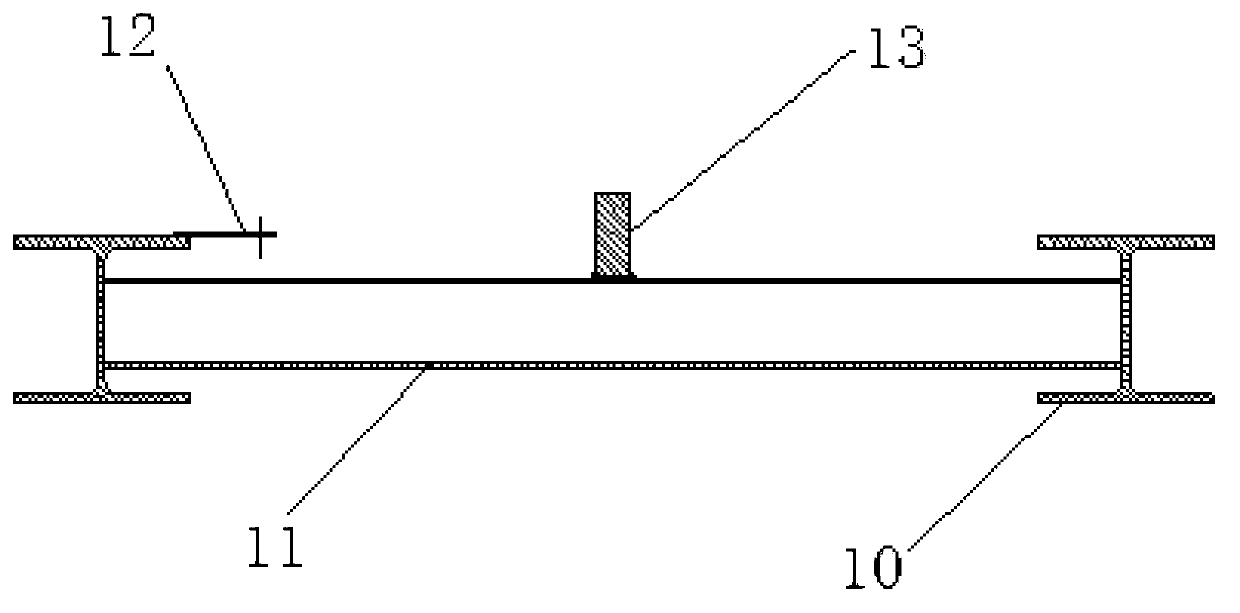

[0026] like image 3 , Figure 4 As shown, the supporting device 10 of the present invention includes a chassis 11, a hinged plate 12 is arranged on a platform at one side of the chassis 11, and a vertical pin 13 is arranged at the center of the top of the chassis 11.

[0027] like figure 1 , Figure 5 , Image 6 As shown, the guide rod bracket 20 of the present invention includes a rotating base plate 21, and a shaft sleeve 22 is arranged at the center of the rotating base plate 21. There is another hinge plate 23, and four corners of the rotating base plate 21 are respectively provided with a guide rod 24 protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com