Processing method of lens cone inner wall die

A processing method and lens barrel technology, which can be applied to electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, high cost, waste of mold base, etc., and achieve material cost saving, consistent effect and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

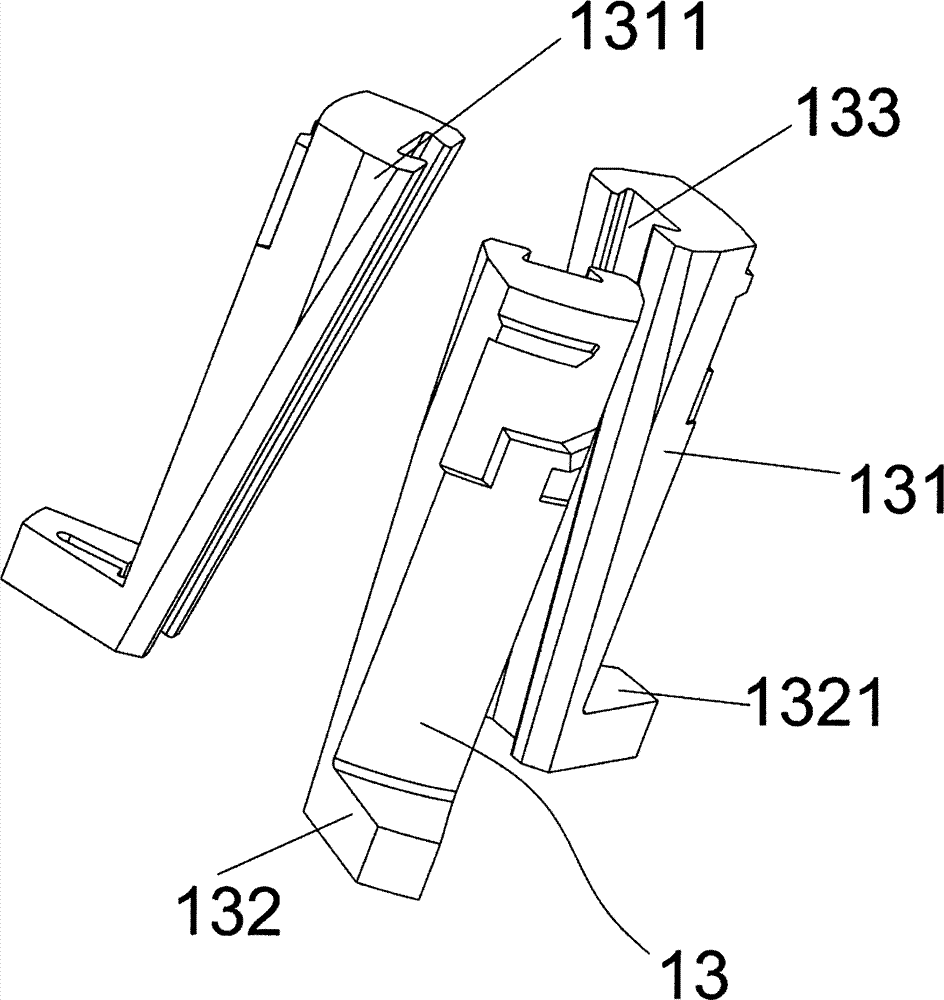

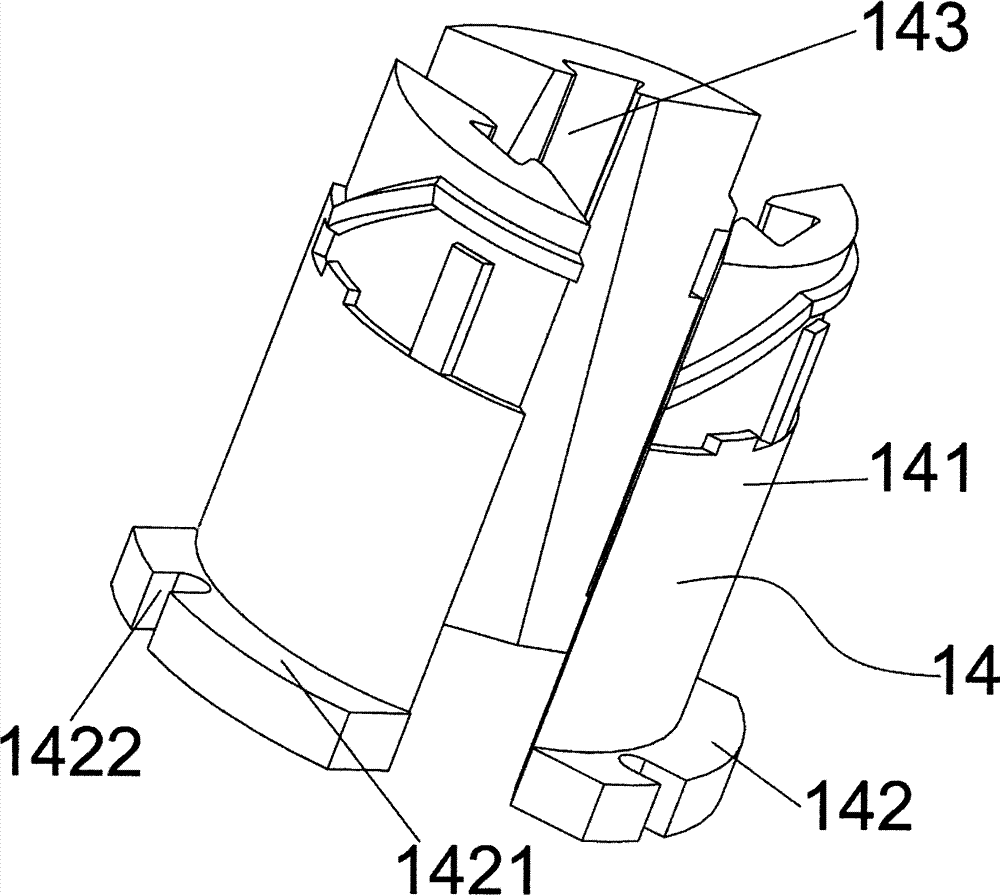

[0039] Such as Figure 1-7 As shown, the present invention provides a method for processing a lens barrel inner wall mold, the method comprising:

[0040] S1: A hexagonal platform 11 is processed by wire cutting according to the size requirements. The upper end of the hexagonal platform 11 is thin and the lower end is thick, and there is a vertical convex rail 111 in the center of each side of the hexagonal platform. The cross-sectional shape of the protruding rail 111 is trapezoidal, the outer side close to the protruding rail 111 is the long side of the trapezoid, and the inner side close to the protruding rail 111 is the short side of the trapezoid.

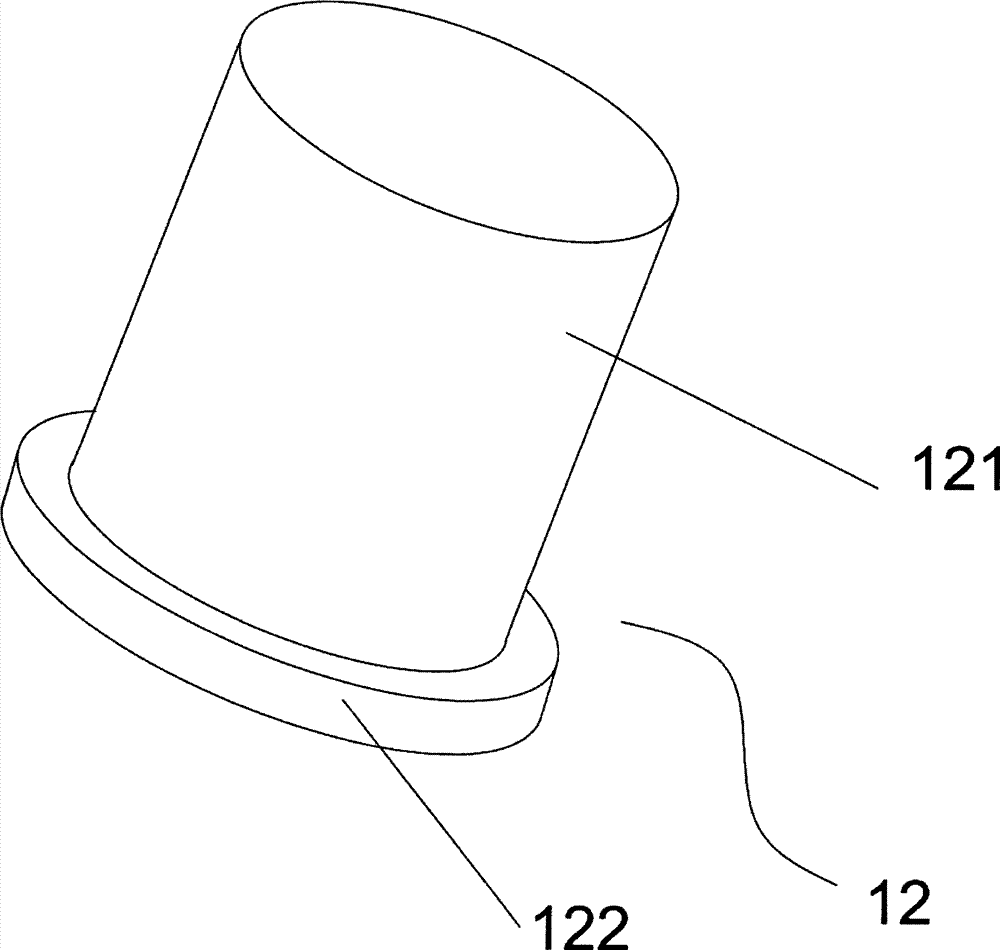

[0041] S2: According to the size requirements, two cylindrical mold blanks 12 with pallets are first processed by CNC machine tools. The cylindrical mold blanks include a cylindrical main body 121 and a disc-shaped pallet 122. The diameter of the cylindrical main body 121 is It is the same diameter as the cylindrical insert b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com