Construction method of phosphoric acid functionalized carbon nanometer pipe-titanium dioxide composite nanometer photocatalyst

A nano-photocatalyst and acidifying carbon nanotube technology, applied in the field of photocatalyst construction, can solve problems such as poor activity, and achieve the effects of promoting separation, mild reaction conditions and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

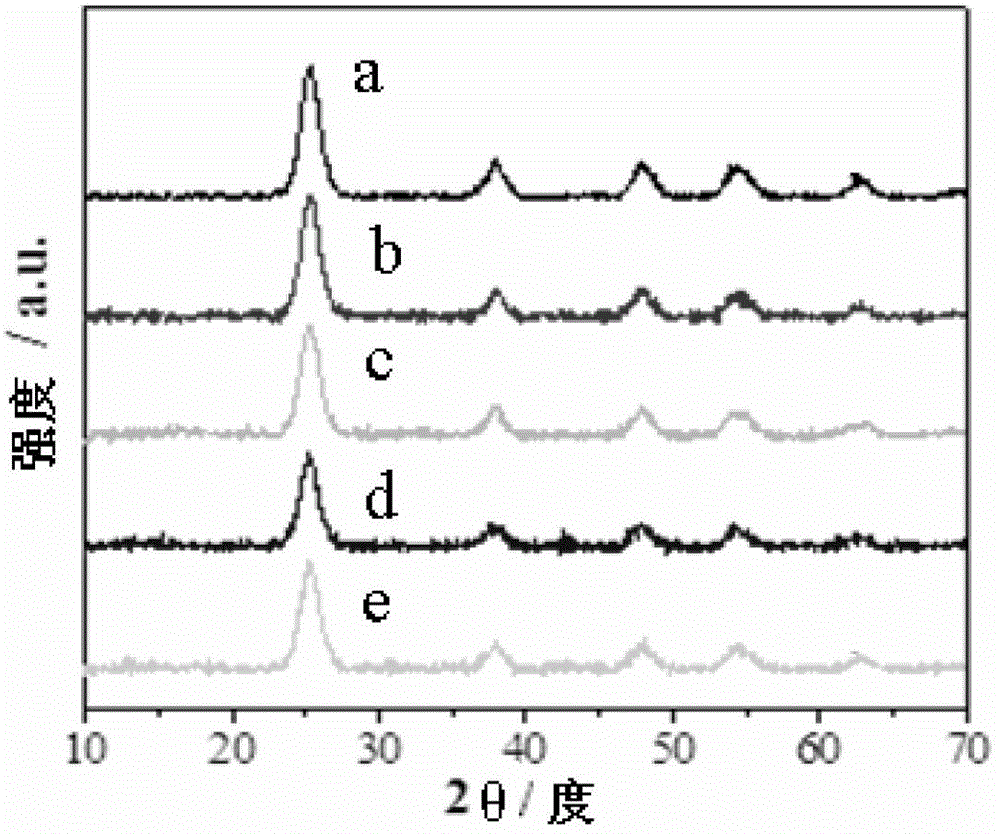

[0022] Specific implementation mode 1: The construction method of phosphoric acid functionalized carbon nanotube-titanium dioxide composite nano photocatalyst in this embodiment is carried out according to the following steps:

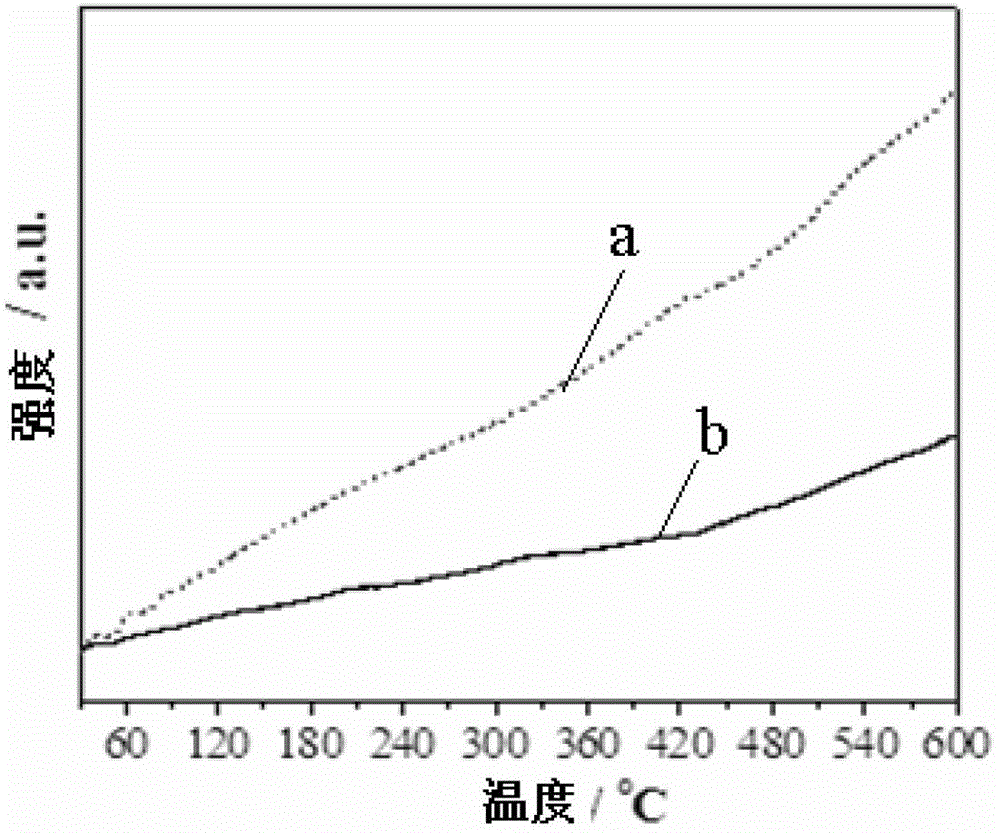

[0023] 1. Add carbon nanotubes to concentrated nitric acid, reflux at 120°C to 140°C for 4 to 8 hours, centrifuge, wash, and dry to obtain acidified carbon nanotubes;

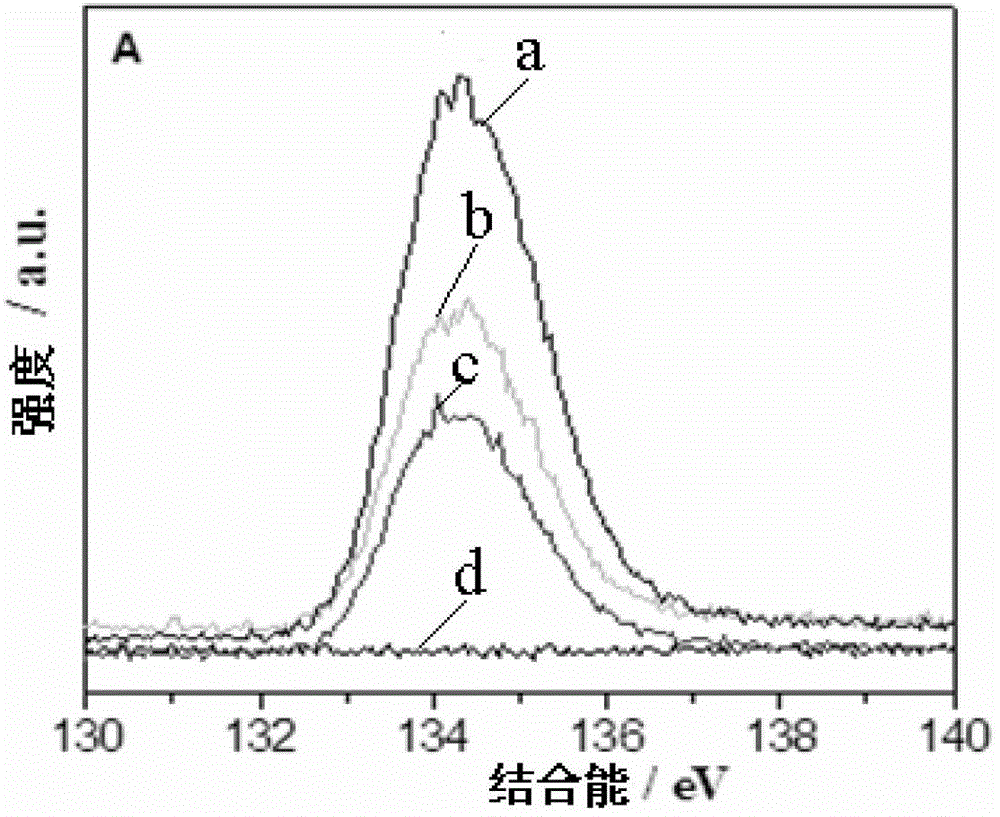

[0024] 2. Add the acidified carbon nanotubes to the phosphoric acid aqueous solution with a concentration of 0.1mol / L~1.0mol / L, stir for 20min~60min, ultrasonic for 30min~60min, then centrifuge, wash, dry, roast and grind to obtain phosphoric acid functionalized carbon nanotubes;

[0025] In step 2, the mass ratio of the acidified carbon nanotubes to the aqueous phosphoric acid solution is 1: 20 to 30;

[0026] 3. Add 0.05 to 0.5 parts by mass of phosphoric acid functionalized carbon nanotubes to 40 to 60 parts by mass of butyl titanate, and then repeat the order of stirring for 10 to ...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass fraction of concentrated nitric acid described in step one is 65%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the reflux is carried out at 130° C. for 5 hours. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com