Method for preparing titanium-based graphene coating for solid phase microextraction

A technology of carboxylated graphene and graphene, which is applied in the fields of analytical chemistry and environmental analysis, can solve the problems of limiting the service life of quartz fibers and being easy to break, and achieve the effects of long-term use, strong adsorption, and improved extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

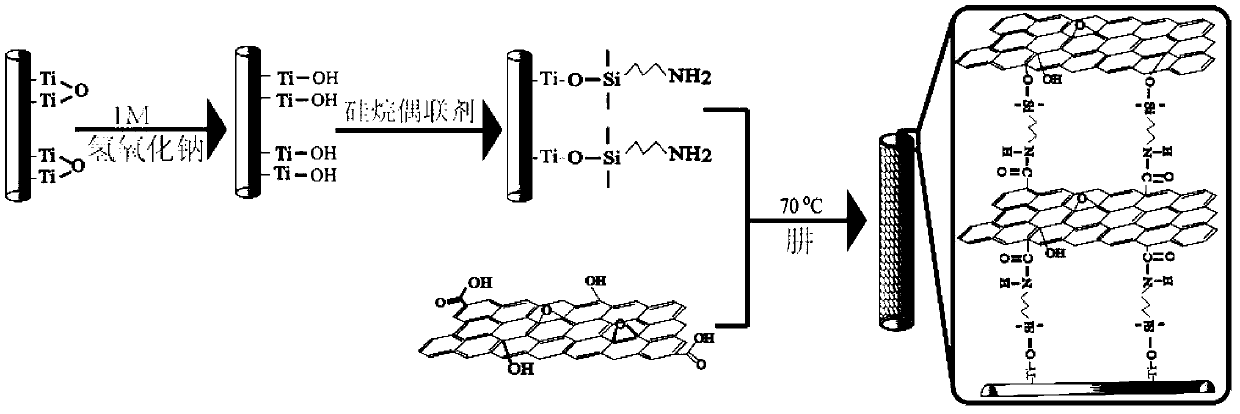

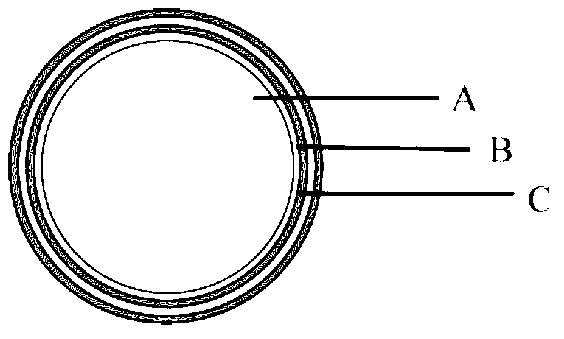

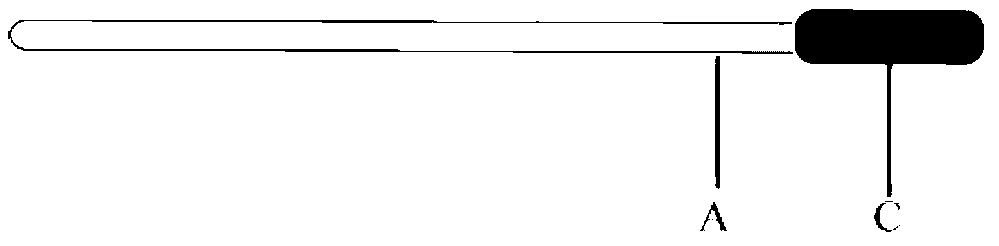

[0033] see figure 1 —— image 3 , Take a 10cm-long titanium wire, and sonicate it in 5mL acetone, methanol and deionized water for 5min to remove surface dirt. After taking it out, it was immersed in a 1mol / L sodium hydroxide solution for hydroxylation treatment in a water bath at 70°C for 1 hour, and immediately placed in an oven at 120°C to react for 30 minutes. After the titanium wire is taken out, use 1 mol / L hydrochloric acid solution, methanol and deionized water to wash the free hydroxide ions on the surface. After drying, the titanium wire was immersed in a 10% toluene solution of 3-propyltriethoxysilane for 12 hours for silanization. Under ultrasonic conditions, 0.1 mg of carboxylated graphene was added to 5 mL of N,N'-dimethylformamide, followed by 0.1 mg of N,N'-dicyclohexylcarbodiimide, and mixed well. Remove the titanium wire from the silanization reagent, and immediately put it in the oven for drying and stabilization; after the drying, insert the titanium wire ...

Embodiment 2

[0036] According to the above experimental scheme, the prepared titanium-based graphene solid phase microextraction coating was compared with the commercial solid phase microextraction coating PDMS:

[0037] 1) Use commercial SPME's 100μm thick PDMS to age at 280°C for 30min, immerse it in 8mL 0.1μg / L phthalate solution at 70°C in a water bath, 400r / min speed, potassium chloride At a concentration of 20%, extract for 40 minutes; insert the extracted extraction head directly into the GC port, analyze at 280°C for 5 minutes, and perform GC-MS analysis to obtain Figure 5 The result shown.

[0038] 2) Use the titanium-based graphene solid phase microextraction coating to extract the prepared phthalate solution under the same conditions, and then perform GC-MS analysis to obtain Figure 5 The result shown.

[0039] by Figure 5 As shown, the extraction effect of the titanium-based graphene micro-extraction coating prepared in Example 1 is better than that of a commercial 100 μm thick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com