Microfiltration machine riding wheel and manufacturing method thereof

A manufacturing method and technology of a microfiltration machine, which can be used in ultrafiltration and other directions, and can solve the problems of poor wear resistance of the supporting roller of the microfiltration machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

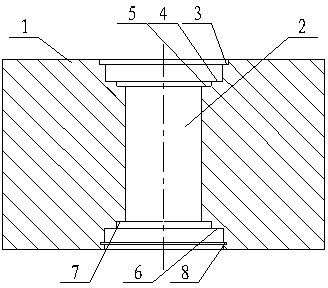

[0013] Such as figure 1 As shown, the supporting wheel of the microfiltration machine according to the embodiment of the present invention includes a body 1, which is made of nylon double 66, and has a shaft hole 2 in the center of the body 1, and on the body 1 on the side of the shaft hole 2 There are first circular platform 3, second circular platform 4, and third circular platform 5 successively from the outside to the inside, the diameters of the first circular platform 3, the second circular platform 4, and the third circular platform 5 decrease successively, and the width of the second circular platform 4 is greater than The width of the first circular platform 3 and the second circular platform 5; on the body 1 on the other side of the shaft hole 2, a fourth circular platform 6 and a fifth circular platform 7 are sequentially opened from the outside to the inside, and the width of the fourth circular platform 6 is Greater than the width of the fifth platform 7, an annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com