Sponge cadmium filtering and feeding device and sponge cadmium filtering and feeding method

A feeding device, sponge cadmium technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of sponge cadmium oxidation, poisoning hidden dangers, quality decline, etc., to reduce oxidation, reduce contact area and time, The effect of less material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

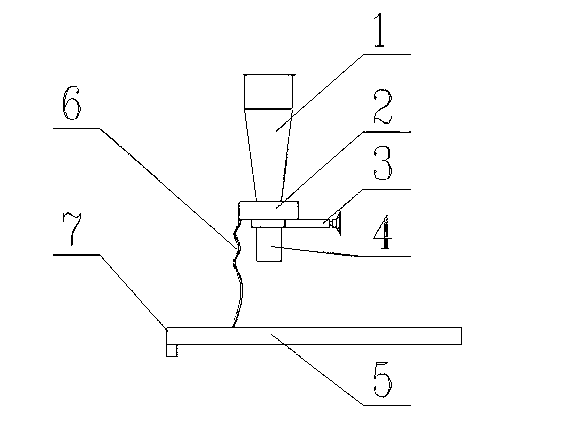

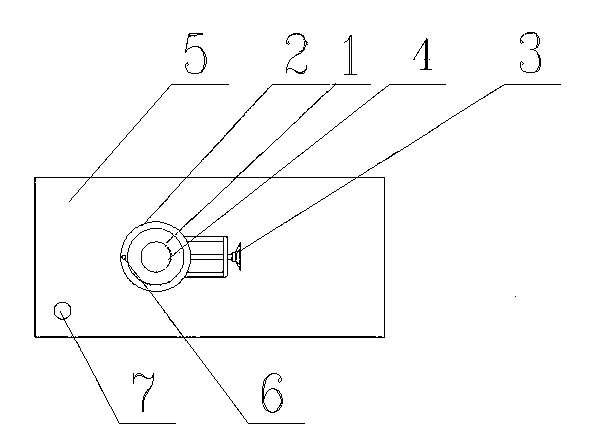

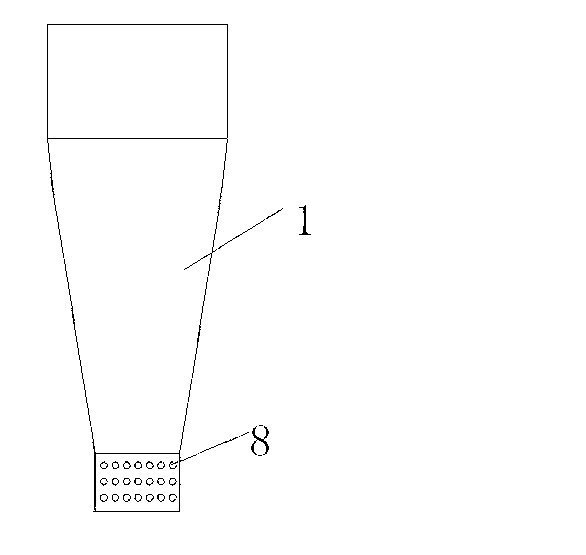

[0029] A sponge cadmium filtering and feeding device, comprising a silo 1 with upper and lower openings, a silo liquid accumulation plate 2 surrounding the bottom of the entire silo, a silo lower material tube 4 connected to the outlet at the lower end of the silo, and placed under a briquetting machine 9 And surround the waste liquid tray 5 of the entire briquetting machine 9; the bottom side wall of the silo 1 is provided with a plurality of filter holes 8 for the waste liquid to flow out; A pumping plate valve 3 is provided; the hopper fluid tray 2 is connected to the waste liquid tray 5 through the liquid outlet pipe a6, and the bottom of the waste liquid tray 5 is provided with a liquid outlet pipe b7 for the waste liquid to flow out.

[0030] The silo feeding pipe 4 is arranged facing the feeding port of the briquetting machine 9 .

[0031] The outlet at the lower end of the silo 1, the mouth of the liquid outlet pipe a6 and the mouth of the liquid outlet pipe b7 are all...

Embodiment 2

[0035] The structure and working process are the same as in Embodiment 1, except that the pumping plate valve 3 adopts an electric control valve to automatically control the amount of sponge cadmium released this time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com