Fluidization moving series arrangement steam drying system and technology

A fluidized bed drying, tandem technology, applied in drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of low heat exchange intensity, small processing capacity, and difficult water recovery, and achieve reasonable utilization. resources, preventing combustion and explosion, and reducing heat dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further explained below in conjunction with specific examples.

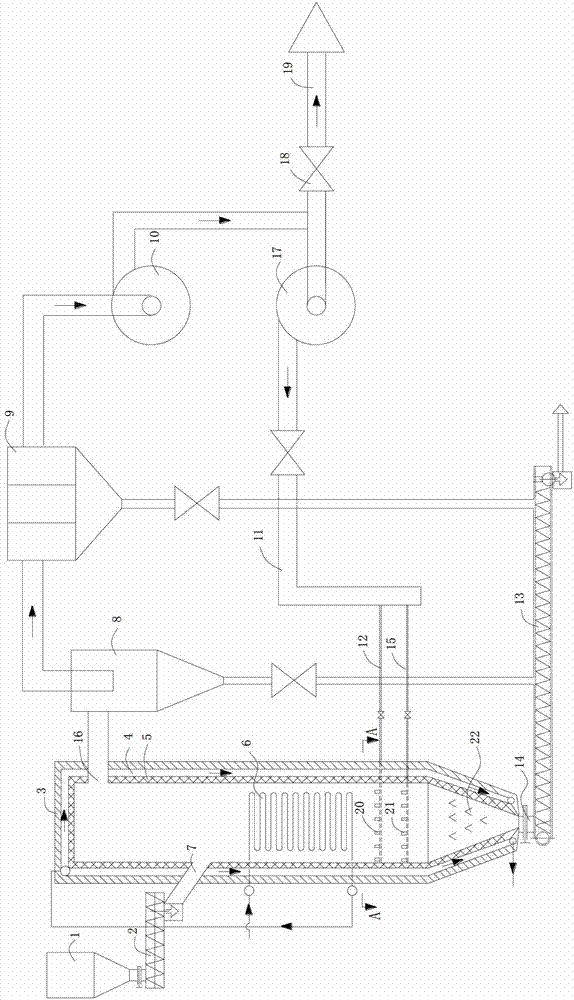

[0052] Such as figure 1 As shown, in the fluidized mobile serial steam drying system in this embodiment, the place where materials are dried is the fluidized bed drying device 3 .

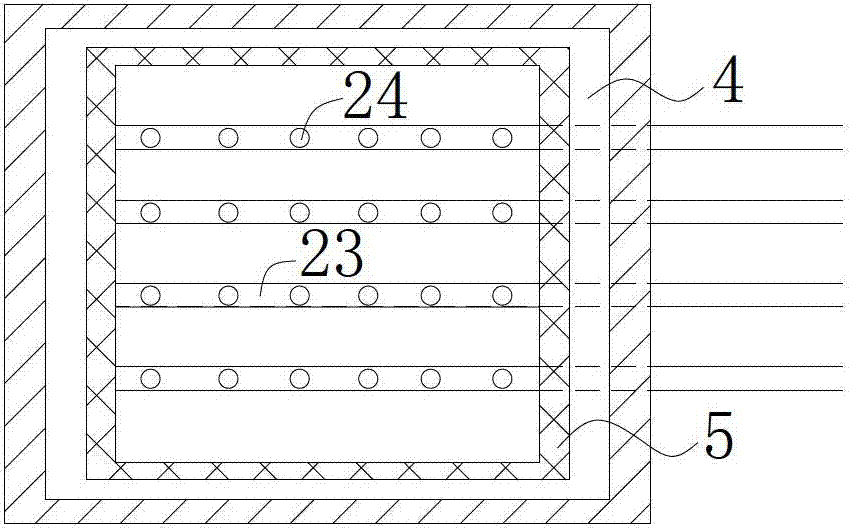

[0053] The top of the fluidized bed drying device 3 is provided with an exhaust port 16 , the middle part is provided with a feed port 7 , and the bottom part is provided with a discharge port 14 . An upper layer air distribution pipe 20 and a lower layer air distribution pipe 21 are sequentially provided between the material inlet 7 and the material outlet 14 . Such as figure 2 As shown, the upper air distribution pipes 20 are horizontally arranged air distribution pipes 23, and air caps 24 are arranged at intervals on the air distribution pipes, which can evenly distribute and send steam. The structure of the lower floor air distribution pipe 21 is the same as that of the upper floor air dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com