Starch-based composite blown film and preparation process of same

A blown film, starch-based technology, applied in the field of starch-based composite blown film and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

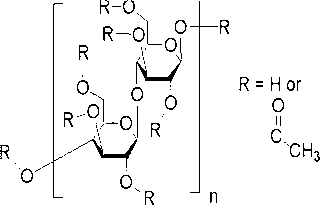

Image

Examples

Embodiment 1

[0036] The starch-based composite blown film material of this embodiment consists of base material tapioca starch, bamboo fiber, acetate-esterified tapioca starch, cellulose acetate, low-density polyethylene, linear low-density polyethylene and auxiliary plasticizer glycerin, reinforcing agent agar , nano-SiO 2 , coupling agent DL-171, stearic acid, antioxidant 1076, light stabilizer o-hydroxybenzophenone, processing lubricant liquid paraffin compounded; the content of tapioca starch in the base material is 40wt%, and acetate The content of starch is 15wt%, the content of bamboo fiber is 15wt%, the content of cellulose acetate is 10wt%, the content of low-density polyethylene is 12wt%, and the content of low-density linear polyethylene in the base material is 8wt%. The dosage of the softening agent glycerin is 30wt% of the starch, the dosage of the reinforcing agent agar is 5wt% of the starch, and the nano-SiO 2 The dosage is 2.5wt% of the starch, the dosage of auxiliary...

Embodiment 2

[0047] In this embodiment, the starch-based composite blown film material is made of base material cornstarch, acetate-esterified cornstarch, cotton fiber, cellulose acetate butyrate, low-density polyethylene, linear low-density polyethylene and auxiliary plasticizer glycerin. Reagent agar, nano-SiO 2 , coupling agent DL-171, stearic acid, antioxidant 1076, light stabilizer o-hydroxybenzophenone, and processing lubricant liquid paraffin; the content of corn starch in the base material is 55wt%, and the acetate The content of starch is 10wt%, the content of cotton fiber is 10wt%, the content of cellulose acetate butyrate is 5wt%, the content of low-density polyethylene is 10wt%, and the content of low-density linear polyethylene in the base material is 10wt%. The dosage of agent plasticizer glycerin is 30wt% of starch, the consumption of reinforcing agent agar is 8wt% of starch, nano-SiO 2 The dosage is 2.5wt% of starch, the dosage of auxiliary coupling agent DL-171 is 3wt% of...

Embodiment 3

[0057] The starch-based composite blown film material of this embodiment consists of base material tapioca starch, acetate-esterified tapioca starch, cotton fiber, cellulose acetate, low-density polyethylene, linear low-density polyethylene and auxiliary plasticizer glycerin, reinforcing agent agar , nano-SiO 2 , coupling agent DL-171, stearic acid, antioxidant 1076, light stabilizer o-hydroxybenzophenone, and processing lubricant liquid paraffin; the content of tapioca starch in the base material is 60wt%, and acetate The content of starch is 10wt%, the content of cotton fiber is 10wt%, the content of cellulose acetate butyrate is 5wt%, the content of low-density polyethylene is 10wt%, and the content of low-density linear polyethylene in the base material is 5wt%, Auxiliary plasticizer glycerin dosage is 30wt% of starch, the dosage of strengthening agent agar is 8wt% of starch, nano-SiO 2 The dosage is 2.5wt% of the starch, the dosage of auxiliary coupling agent DL-171 is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com