Method for preparing magnesium-oxy-chloride cement by utilizing chromium slag produced through salt sub-melting technology

A technology of magnesium oxychloride cement and sub-molten salt, which is applied in the field of resource utilization of chromium slag, can solve the problems of concentrated heat release, cracking of hardened body, long duration, etc., and achieve simple and easy process and equipment flow, and realize resource utilization Use and improve the effect of structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

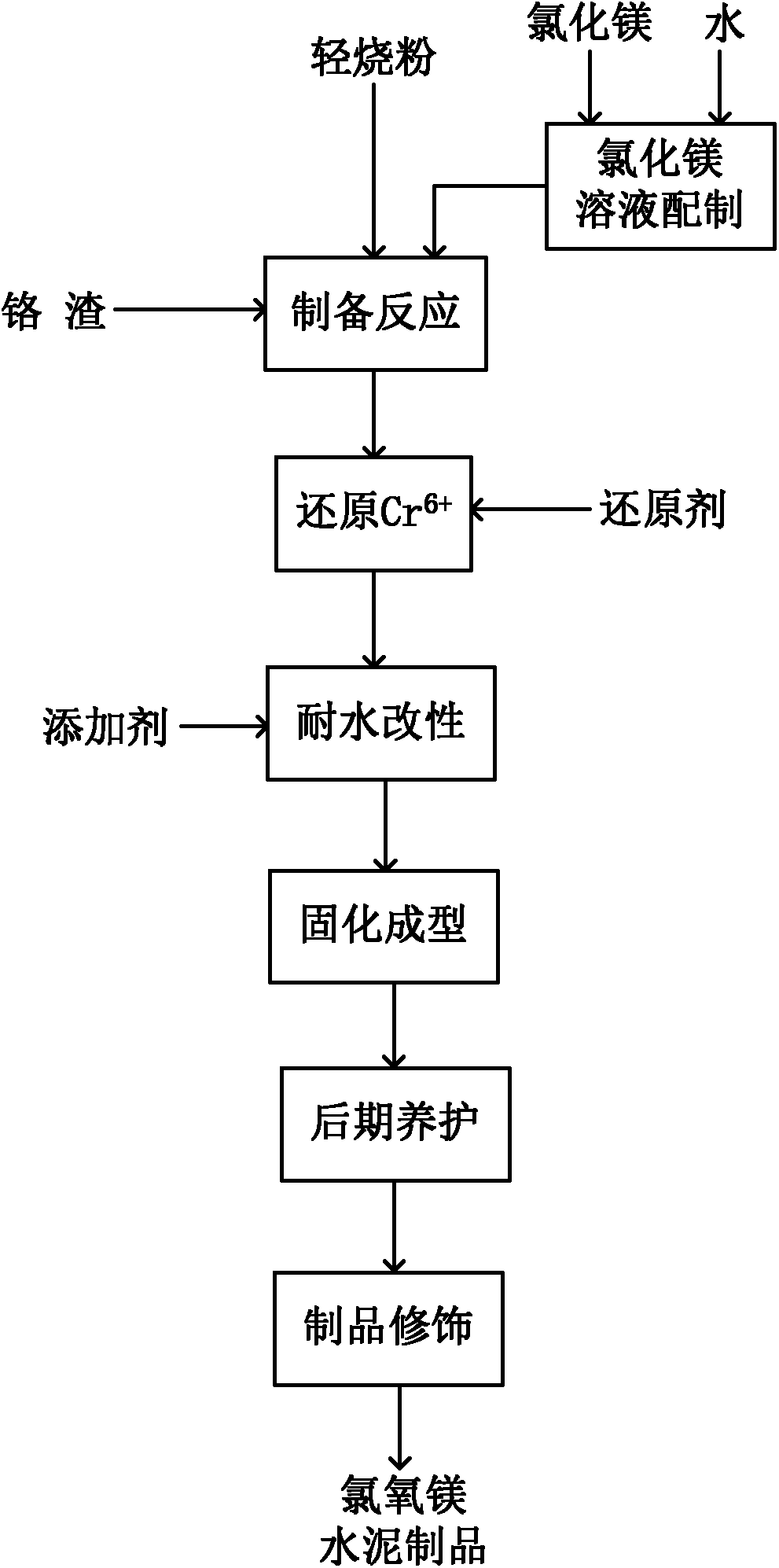

Method used

Image

Examples

Embodiment 1

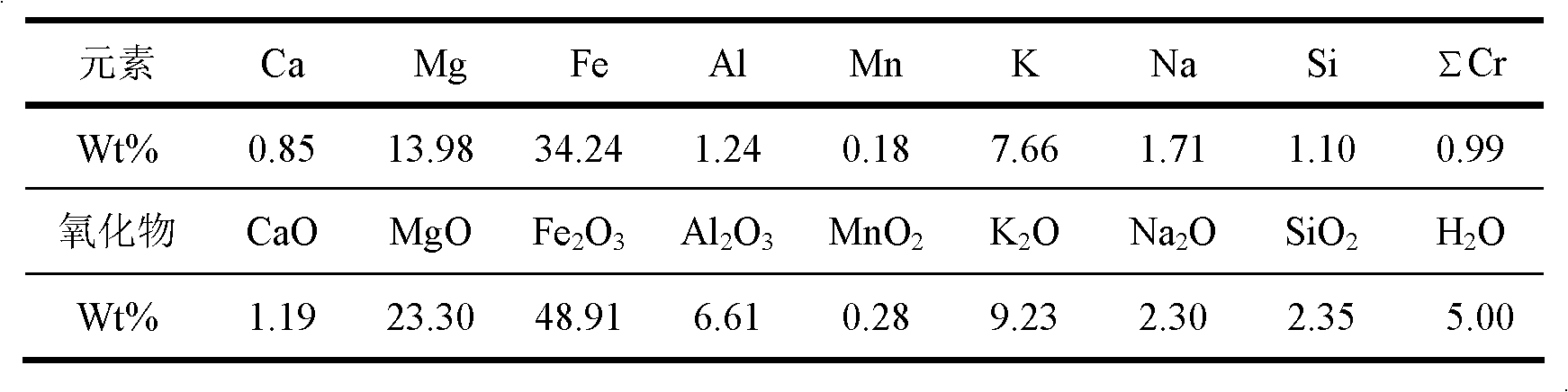

[0043] Experimental ingredients: Liaoning Haicheng magnesite light burnt powder (passed through a 200 mesh sieve, the composition is shown in Table 2) 135g, chromium slag (passed through a 300 mesh sieve, the composition is shown in Table 1) 70g, magnesium chloride hexahydrate 101.5g, Ferrous chloride tetrahydrate 5g, calcium hydrogen phosphate dihydrate 8.5g, deionized water 110ml.

[0044] Experimental conditions: the molar ratio of magnesium oxide, magnesium chloride and water in magnesite lightly burned powder is 6:1:18, the theoretical excess of hexavalent chromium in ferrous chloride relative to chromium slag is 10%, and the addition amount of chromium slag is 20%. The amount of calcium hydrogen phosphate modifier added is 2%; room temperature (about 28°C), stirring speed 150rpm, reaction time 0.5h, curing molding time 24h, curing time 5 days, water resistance test time 28 days.

[0045] Experimental results: According to the cement product strength inspection standard, ...

Embodiment 2

[0047] Experimental ingredients: Liaoning Haicheng magnesite lightly burned powder (passed through a 200-mesh sieve, the composition is shown in Table 2) 135g, chromium slag (passed through a 300-mesh sieve, the composition is shown in Table 1) 63.5g, magnesium chloride hexahydrate 101.5g, Ferrous chloride tetrahydrate 4.5g, calcium hydrogen phosphate dihydrate 7.7g, deionized water 81ml.

[0048] Experimental conditions: the molar ratio of magnesium oxide, magnesium chloride and water in magnesite lightly burned powder is 6:1:15, the theoretical excess of ferrous chloride relative to hexavalent chromium in chromium slag is 10%, and the addition amount of chromium slag is 20%. The amount of calcium hydrogen phosphate added is 2%; room temperature (about 28°C), stirring speed 150rpm, reaction time 0.5h, curing molding time 24h, curing time 5 days, water resistance test time 28 days.

[0049] Experimental results: According to the strength inspection standard of cement products,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com