Electrolyte solution for negative lithium titanate battery, lithium ion battery and preparation method thereof

A negative electrode lithium titanate, lithium ion battery technology, applied in the direction of electrolyte storage battery manufacturing, secondary battery, non-aqueous electrolyte storage battery, etc., can solve the problems of affecting the electrochemical performance of the battery, using a large amount of organic solvents, and hidden dangers of battery safety, etc. Achieve the effect of easy industrialization, inhibition of reduction reaction, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the electrolyte for lithium ion batteries with lithium titanate as the negative electrode includes the following components in weight percentage: lithium hexafluorophosphate 15%, fluoroethylene carbonate 3%, vinylene carbonate 2% and solvent 80%; among them, the solvent It is made by mixing ethylene carbonate, ethyl methyl carbonate, diethyl carbonate and propylene carbonate in a volume ratio of 1:1:1:0.5.

[0038] The lithium ion battery using the electrolyte in this embodiment includes a positive electrode, a negative electrode, and an electrolyte, wherein the negative electrode includes 85wt.% of single-phase lithium titanate (primary particles are nanoscale), 4wt.% of carbon nanotubes, and 6wt.% .% conductive carbon black, 1.5wt.% sodium carboxymethyl cellulose, 2.5wt.% styrene butadiene rubber and 1wt.% oxalic acid; the positive electrode includes 92.5wt.% LiFePO 4 , 1wt.% carbon nanotubes, 2.5wt.% conductive carbon black and 4wt.% LA132.

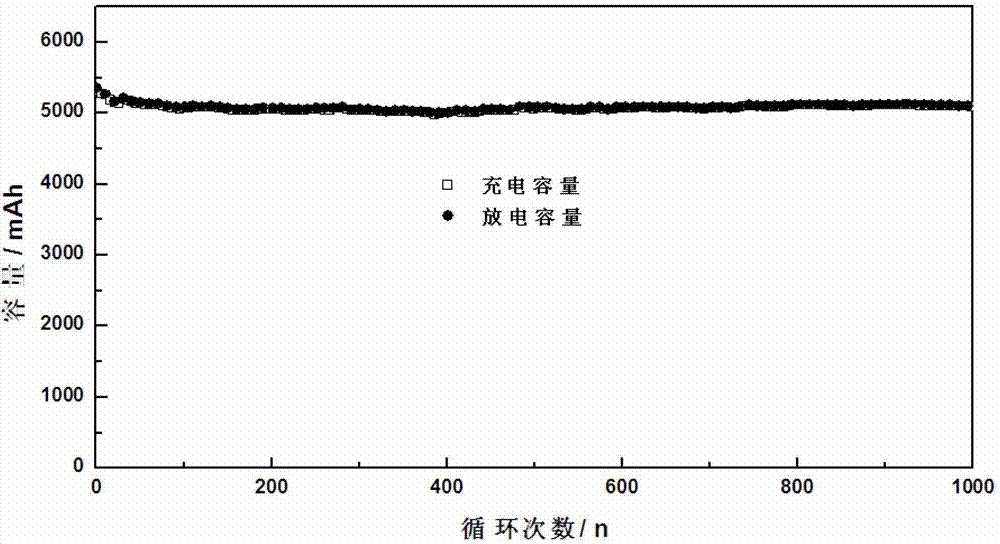

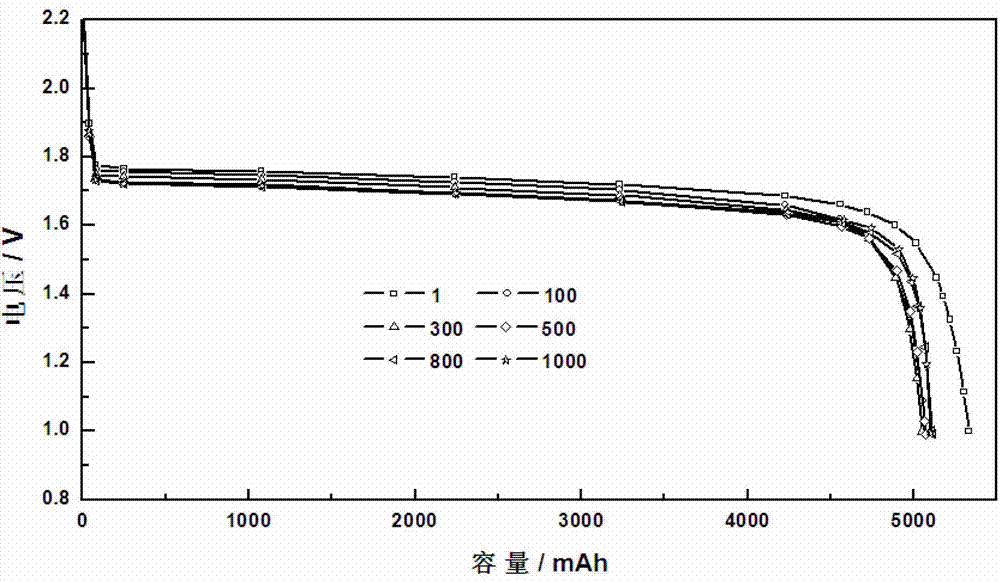

[0039] Th...

Embodiment 2

[0049] In this embodiment, the electrolyte for lithium ion batteries using lithium titanate as the negative electrode includes the following components in weight percentage: lithium hexafluorophosphate 10%, lithium bisoxalate borate 2% and solvent 88%; wherein the solvent is ethylene carbonate, methyl ethyl carbonate Ester, diethyl carbonate and propylene carbonate are mixed in a volume ratio of 1:1:1:1.

[0050] The lithium ion battery using the electrolyte in this embodiment includes a positive electrode, a negative electrode, and an electrolyte, wherein the negative electrode includes 94wt.% of modified lithium titanate coated with carbon (primary particles are nano-level), and 3wt.% of Conductive carbon black, 2.5wt.% LA132 and 0.5wt.% sodium carboxymethyl cellulose; positive electrode includes 95wt.% 0.5Li 2 MnO 3 ·0.5LiNi 0.5 Mn 0.5 O 2 , 1wt.% conductive carbon black, 1wt.% conductive graphite, 2wt.% LA132 and 1wt.% sodium carboxymethyl cellulose.

[0051] The method for pre...

Embodiment 3

[0060] In this embodiment, the electrolyte for lithium ion batteries with lithium titanate as the negative electrode includes the following components by weight percentage: lithium hexafluorophosphate 12.5%, lithium bisoxalate borate 1.5%, 1,3-propane sultone 1%, and sodium carbonate Vinyl ester 1% and solvent 84%; the solvent is made by mixing ethylene carbonate, ethyl methyl carbonate, diethyl carbonate and propylene carbonate in a volume ratio of 1:1:1:2.

[0061] In this embodiment, a lithium ion battery using the electrolyte includes a positive electrode, a negative electrode, and an electrolyte, wherein the negative electrode includes a modified lithium titanate (primary particles of nanometer level) with a surface of 89.5wt.% of carbon coated, 3wt. % Conductive carbon black, 2wt.% conductive graphite, 5wt.% LA133 and 0.5wt.% oxalic acid; the positive electrode includes 90wt.% LiNi 1 / 3 Mn 1 / 3 Co 1 / 3 O 2 , 3wt.% conductive carbon black, 2wt.% conductive graphite, 4wt.% LA133 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com