Cooling module and assembling method thereof

A technology of heat dissipation module and assembly method, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as affecting the efficiency of heat energy transfer, increasing the thermal resistance of two adjacent components, and failing to fully fit the contact surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

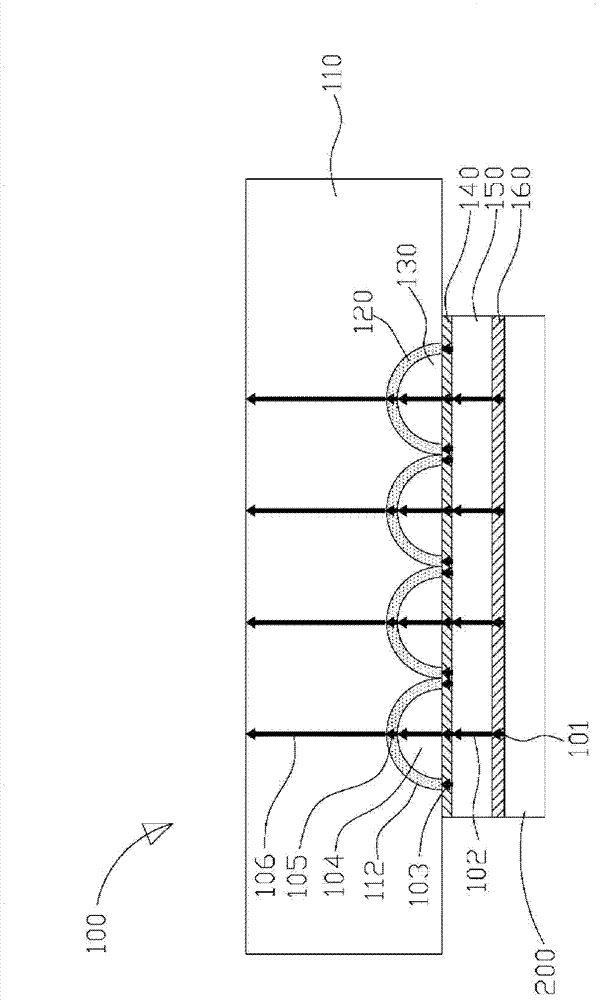

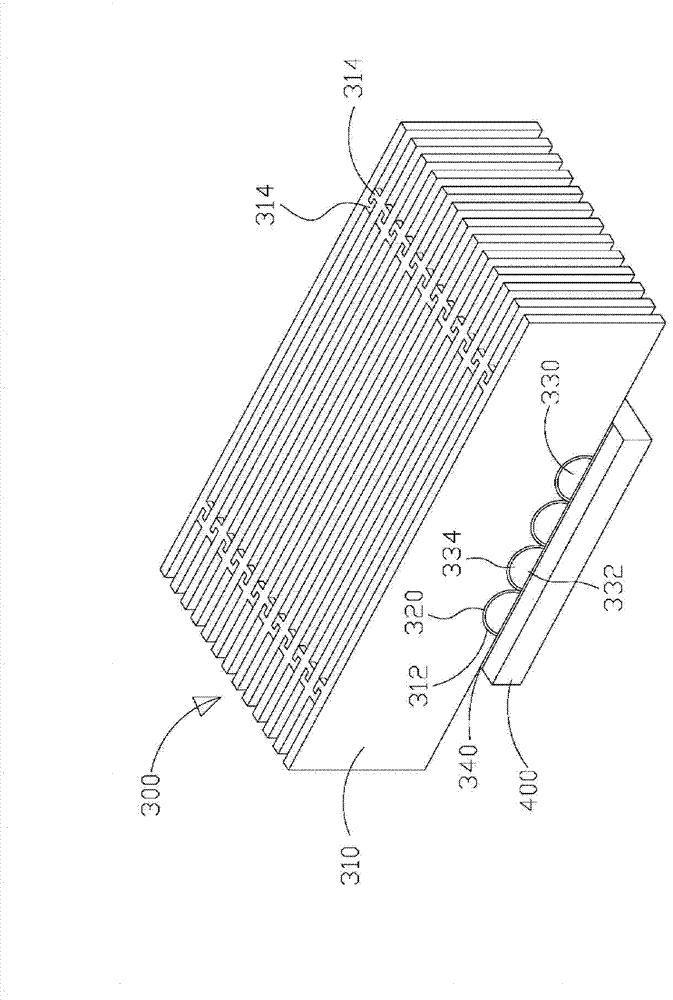

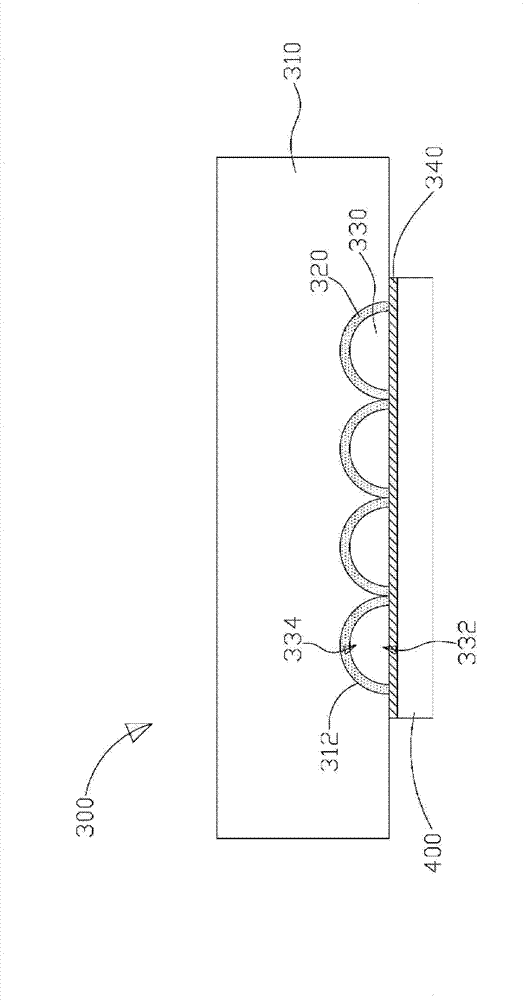

[0056] see Figure 2A , Figure 2B and image 3 , which are a schematic perspective view, a schematic plan view and a flowchart of an assembly method of the heat dissipation module in the first preferred embodiment of the present invention.

[0057]As shown in the figure, the heat dissipation module 300 of the first preferred embodiment of the present invention is suitable for a heat generating component 400. The heat dissipation module 300 of the first preferred embodiment includes a plurality of heat dissipation fins 310, a first heat conducting medium 320, A heat pipe 330 and a second heat conducting medium 340 . The plurality of heat dissipation fins 310 are respectively provided with a housing groove 312, the first heat transfer medium 320 is arranged in the accommodation groove 312, the heat pipe 330 passes through a plurality of heat dissipation fins 310, and the heat pipe 330 is arranged on the heat dissipation fin 310 In each accommodating groove 312 , the heat pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com