Diamond compact annular concentric simultaneous casing drilling bit and working method thereof

A technology of diamond composite sheets and drill bits, which is applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve the problems that the casing is difficult to follow the long hole section, frequent accidents, and increase the time for hole making, so as to ensure the diameter of the hole range, bushing follow-up smoothly, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

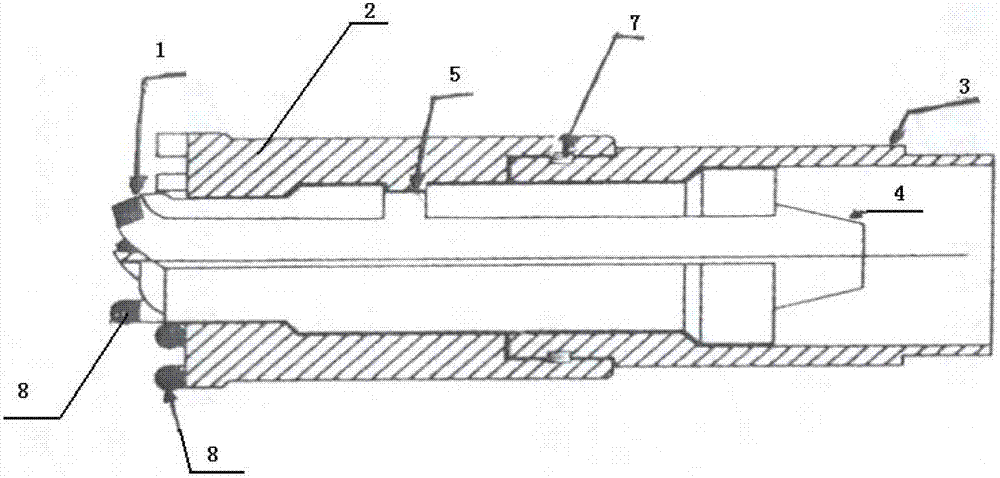

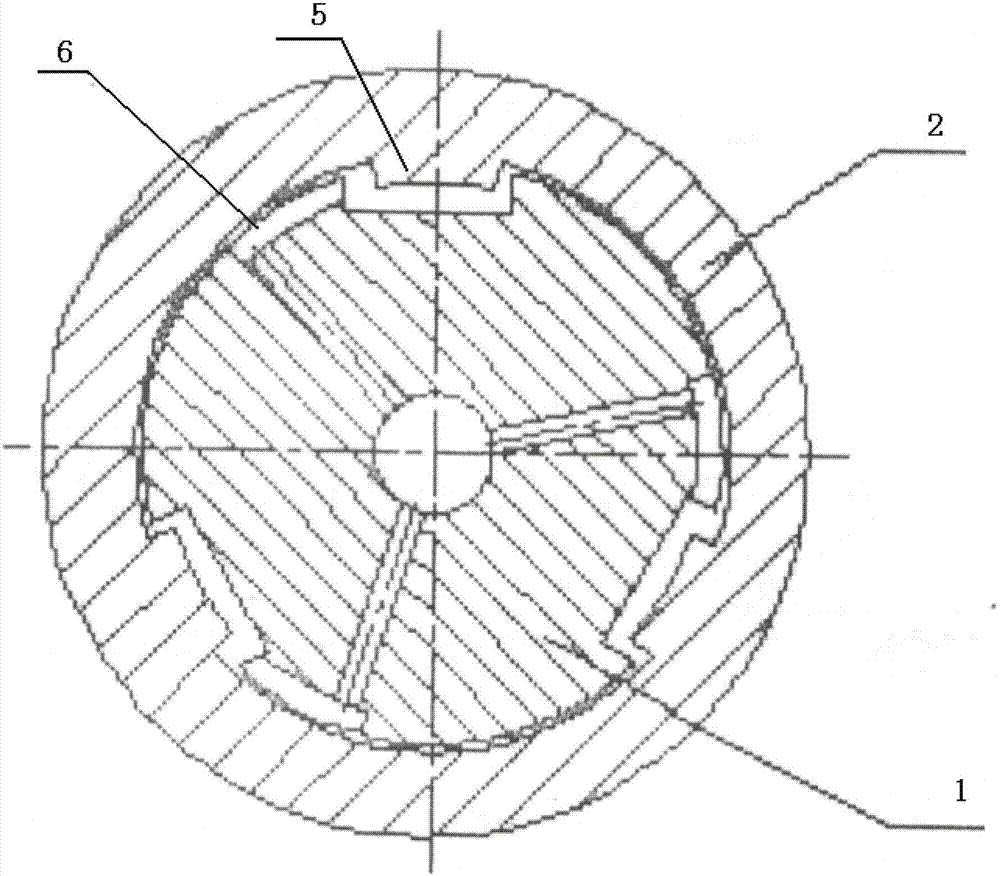

[0047] Such as Figure 1-3 shown.

[0048] A diamond composite annular concentric drill bit, comprising a center drill bit 1, a casing drill bit 2 and a casing shoe 3; the center drill bit 1 is connected to a drill pipe through a drill pipe joint 4, and the casing shoe 3 is connected to the casing threaded connection; a casing bit 2 and a casing shoe 3 are sleeved on the center bit 1, and the bit end face of the casing bit 2 is flush with the bit end of the center bit 1; the center bit 1 It is realized by bonding with the casing bit 2: the center bit 1 rotates in one direction around the axis in the casing bit 2; the casing bit 2 and the casing shoe 3 are connected by relative rotation around the axis through sleeve installation. .

[0049] The bonding structure between the center bit 1 and the casing bit 2 is as follows: the inner wall of the casing bit 2 is provided with an arc-shaped convex key 5 around the axis, and the center bit body 1 is provided with a The male key ...

Embodiment 2

[0053] A diamond compact annular concentric heel pipe drill bit as described in Example 1 is characterized in that the casing drill bit 2 and the casing shoe 3 are both made of 35CrMo alloy structural steel. Before assembly, the 35CrMo alloy structural steel needs to be quenched and tempered, carburized, quenched, and heat treated according to the existing technology to increase the toughness and strength of the casing bit and the casing shoe; Compared with the traditional drilling tool DZ40, the strength of the above-mentioned drilling tool has been greatly improved.

Embodiment 3

[0055] Such as Figure 4 shown. As described in Example 1, a diamond compact annular concentric heel drill bit is characterized in that an internal thread 9 is provided at the position where the casing shoe 3 is connected to the casing 2, and the internal thread is an arc buckle shape.

[0056] The parameters of the arc button-shaped internal thread 9 are left thread, metric increased thread, and the screw moment is 10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com